Railway transportation automatic dumping system

A technology of railway transportation and automatic turning, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems affecting dumping and increasing dumping capacity, and achieve the effects of avoiding waste, increasing dumping capacity, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

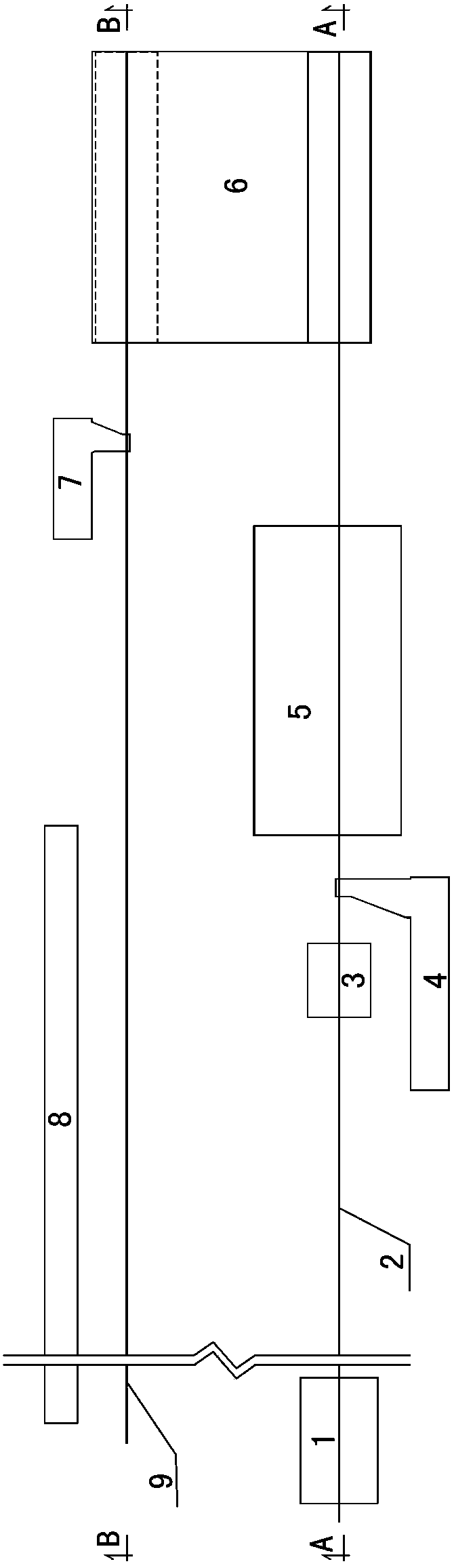

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

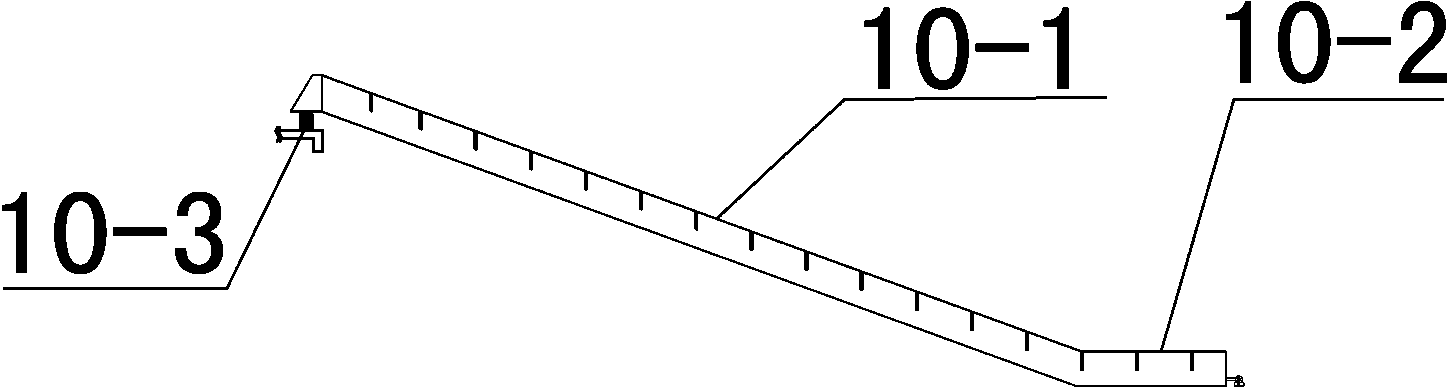

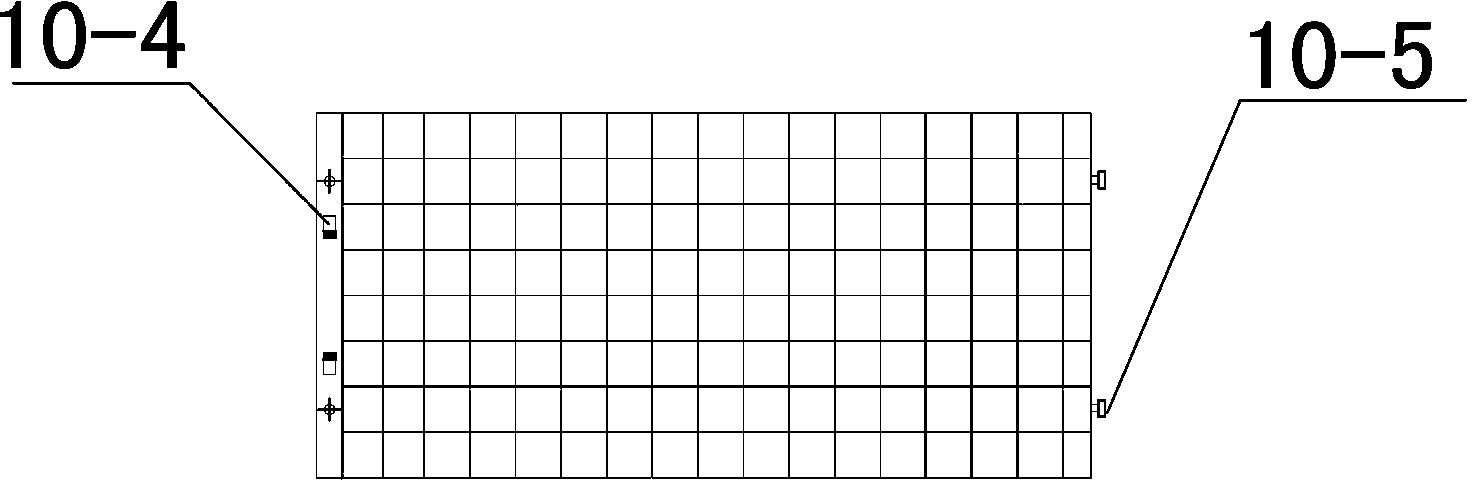

[0024] Such as figure 1 , figure 2 , image 3 As shown, the automatic dumping system for railway transportation of the present invention includes a heavy vehicle track line 2, an empty car track line 9, a dumper 5 arranged on the heavy vehicle track line 2, and a buffer mine 11 located at the dumper 5 below , the tape conveyor 13 located under this buffer ore bin 11 is characterized in that the heavy vehicle track line 2 is arranged parallel to the empty car track line 9, and the end of the heavy vehicle track line 2 and the empty car track line 9 Between vertically be provided with pull car platform 6, be provided with loosening machine track outside described heavy vehicle track line 2, be provided with loosening machine 1 on this loosening machine track, the material frozen in the heavy vehicle compartment is crushed, loosened. Nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com