Blast furnace gas sulfur resource utilization device

A blast furnace gas and resource technology, which is applied in the field of blast furnace gas sulfur resource utilization devices, can solve the problems of low utilization rate of adsorbents, large bed pressure loss, large loading capacity of microcrystalline adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

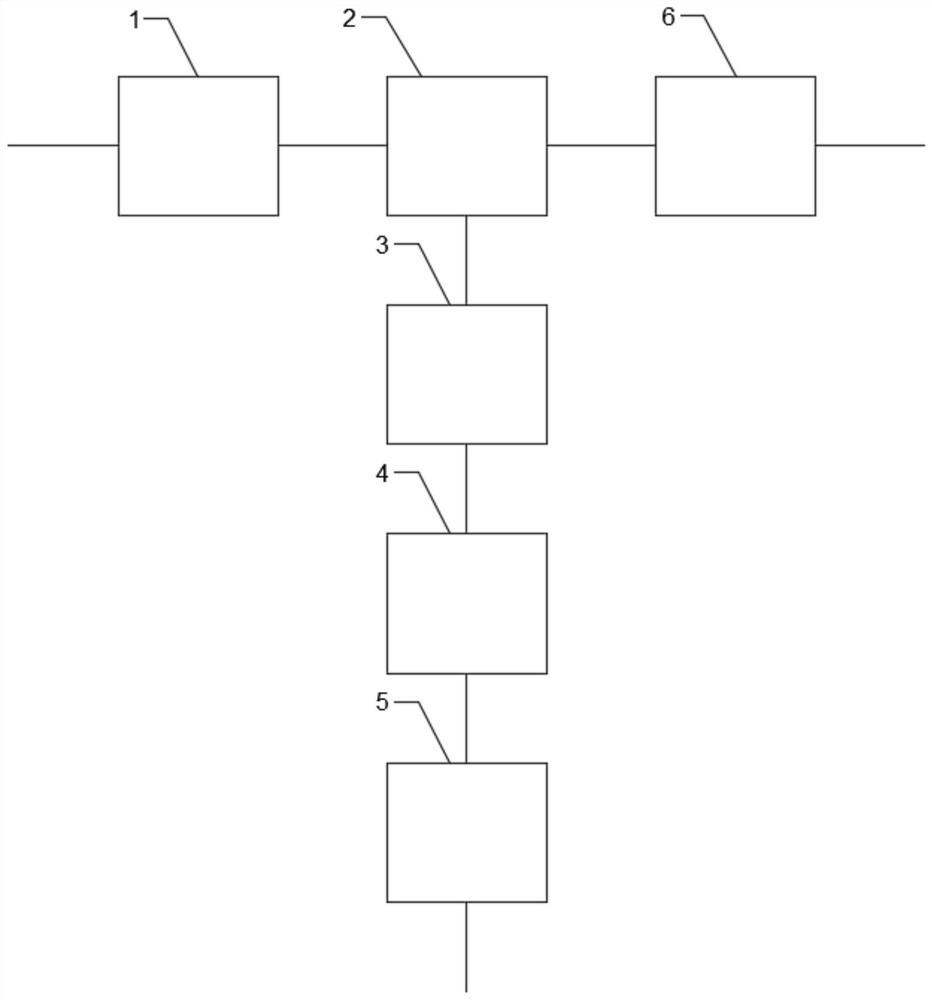

[0043] Such as figure 1 As shown, the blast furnace gas sulfur resource utilization device provided by the embodiment of the present invention includes: a pretreatment unit 1 , an adsorption / desorption unit 2 , a delivery unit 6 , a heating unit 3 , a catalytic unit 4 and a condensation recovery unit 5 .

[0044] Among them, the pretreatment unit 1 includes a plurality of functional sub-modules, which respectively realize different functions, such as dechlorination, cooling and dehydration, heating and dehumidification, filtration and deoxidation, and the like. The inlet of the pretreatment unit 1 is in communication with the blast furnace gas to be treated.

[0045] The inlet of the adsorption / desorption unit 2 is connected to the outlet of the pretreatment unit 1, and the adsorption / desorption unit 2 includes at least two sub-modules, such as an adsorption module and a desorption module, which are used to separate the sulfur-containing substances of the blast furnace gas . ...

Embodiment 2

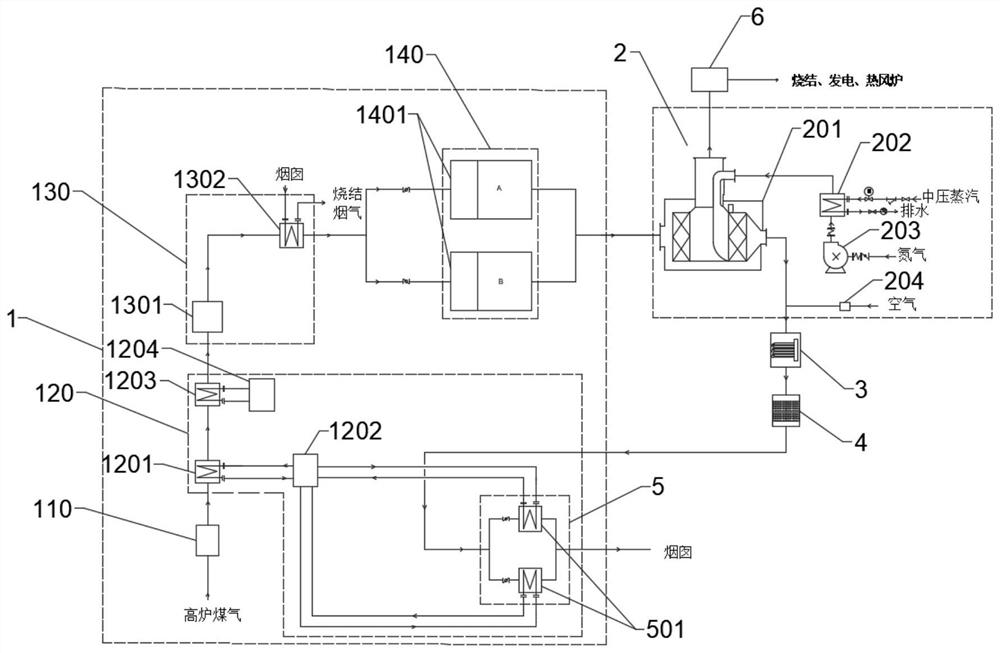

[0053] This embodiment is an optional implementation of the device for utilizing sulfur resources of blast furnace gas in Embodiment 1. Such as figure 2 As shown, in this embodiment, the pretreatment unit 1 includes a dechlorination module 110 , a cooling module 120 , a dehumidification module 130 and a filter deoxygenation module 140 . Wherein, the inlet of the pretreatment unit 1 receives blast furnace gas to be treated, and the received blast furnace gas first enters the dechlorination module 110, and the dechlorination module 110 is used for removing chlorine-containing substances. After the blast furnace gas passes through the dechlorination module 110, it needs to be cooled by the cooling module 120. The cooling can condense the unsaturated water in the gas into supersaturated liquid water, and then remove it through the precision demister, so that the subsequent reheating process The relative humidity of the gas is reduced, thereby ensuring the adsorption efficiency o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com