Integrated-type control system of roll steel heating furnace

A control system and heating furnace technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as uncertainty, and achieve the effect of preventing transmission signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

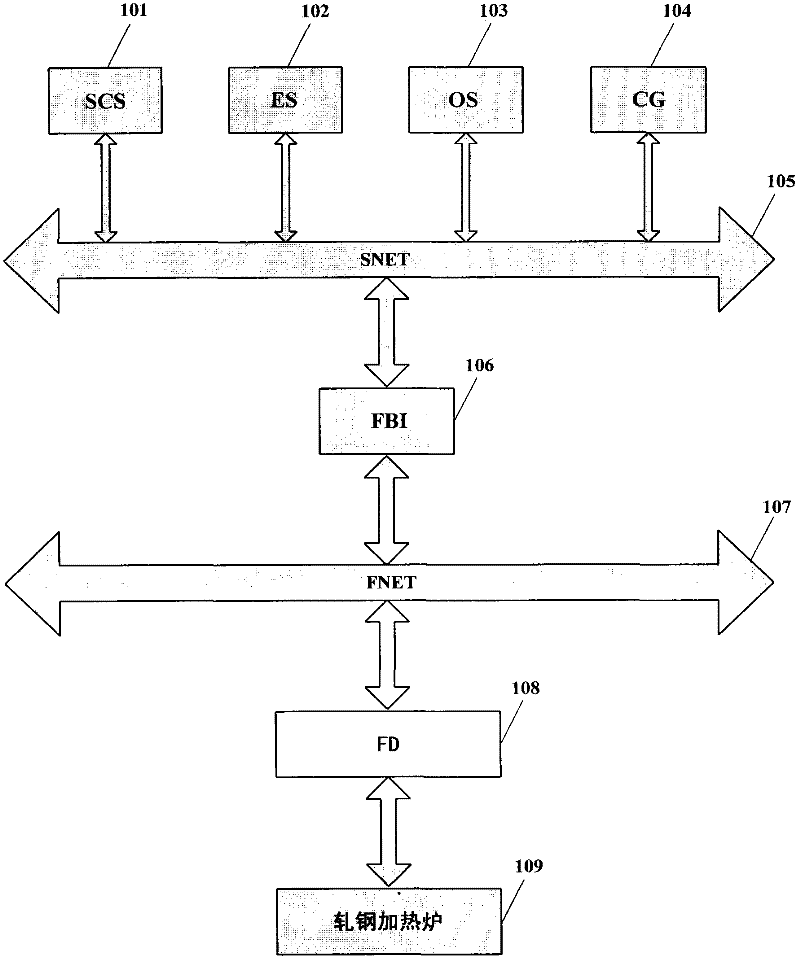

[0115] figure 1 It is a structural schematic diagram of an integrated control system for a rolling heating furnace of the present invention.

[0116] Including: SCS monitoring computer system 101, ES engineer control machine 102, OS operator computer 103, CG computer gateway 104, SNET monitoring network 105, FBI field bus interface 106, FNET field bus network 107, FD field bus instrument and auxiliary equipment 108 .

[0117] The SCS monitoring computer system 101 is used to establish the fault diagnosis model of the steel rolling heating furnace production process, the billet temperature control model, the furnace temperature temperature rise optimization control model, the information fusion of various models, the establishment, update and maintenance of the database and knowledge base, and the realization of Advanced process control strat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com