Nickel iron slag micropowder and preparation method thereof

A technology for ferronickel slag and micropowder, which is applied in the field of ferronickel slag micropowder and its preparation, can solve the problems of undisclosed micronization treatment of ferronickel slag, and achieve the effects of excellent crystallinity, advanced technology and good activity index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

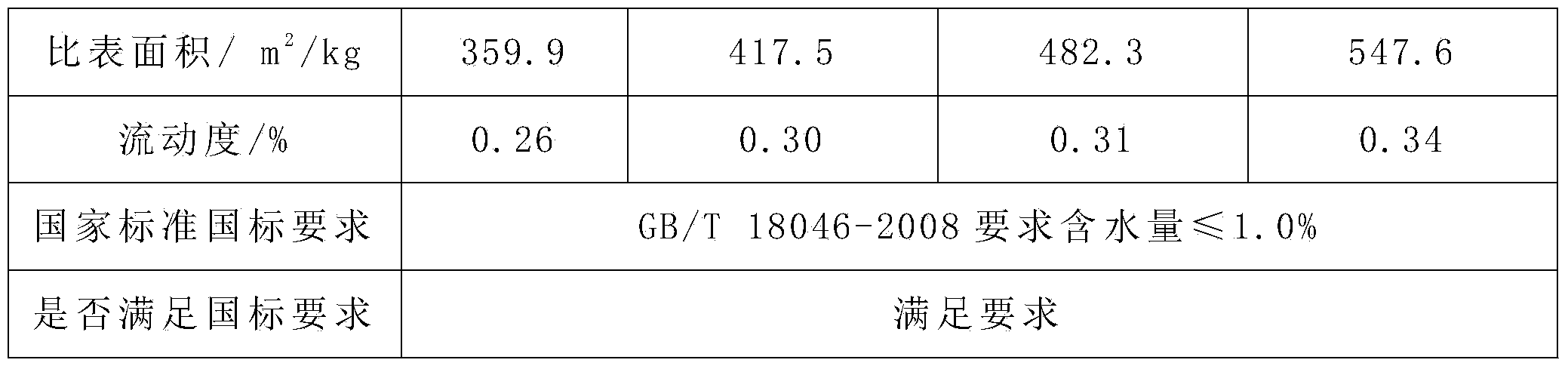

[0037] The present invention provides that the specific surface area is respectively 359.9m 2 / kg, 417.5m 2 / kg, 482.3m 2 / kg, 547.6m 2 / kg of ferronickel slag powder.

[0038] The preparation method of above ferronickel slag fine powder:

[0039] a. Send the ferronickel slag to the iron remover for magnetic separation;

[0040] b. Dry the ferronickel slag after magnetic separation until the water content of the ferronickel slag is less than or equal to 3%, pulverize it, and collect coarse material with a particle size less than 10 mm;

[0041] c. Weigh the coarse material of the prescribed amount, send it into the mill, the rotating speed of the mill is 27.8r / min, carry out grinding, drying, the drying temperature is 500 ℃, cool down, and the grinding temperature is 80 ℃, the ferronickel slag fine powder is obtained;

[0042] d. Send the ferronickel slag fine powder into the separator, and collect the ferronickel slag fine powder with the above different specific surface...

Embodiment 2

[0047] The present invention obtains ferronickel slag micropowders with different specific surface areas by performing a grinding test on ferronickel slag, and compares different ratios according to the method specified in GB / T18046-2008 "Granulated Blast Furnace Slag Used in Cement and Concrete". Surface area of ferronickel slag fine powder is tested for technical indicators.

[0048] 1.1 Activity index determination test

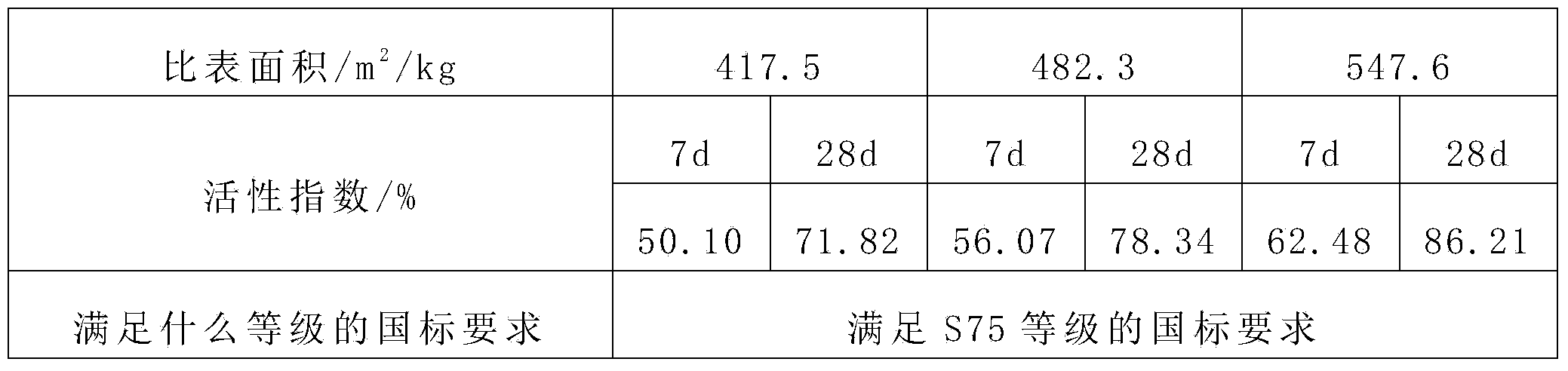

[0049] According to the method specified in GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete", the activity index of nickel-iron slag fine powder 7d and 28d with different specific surface areas was measured, and the results are shown in Table 2;

[0050] Table 2 The activity index value of ferronickel slag powder with different specific surface area

[0051]

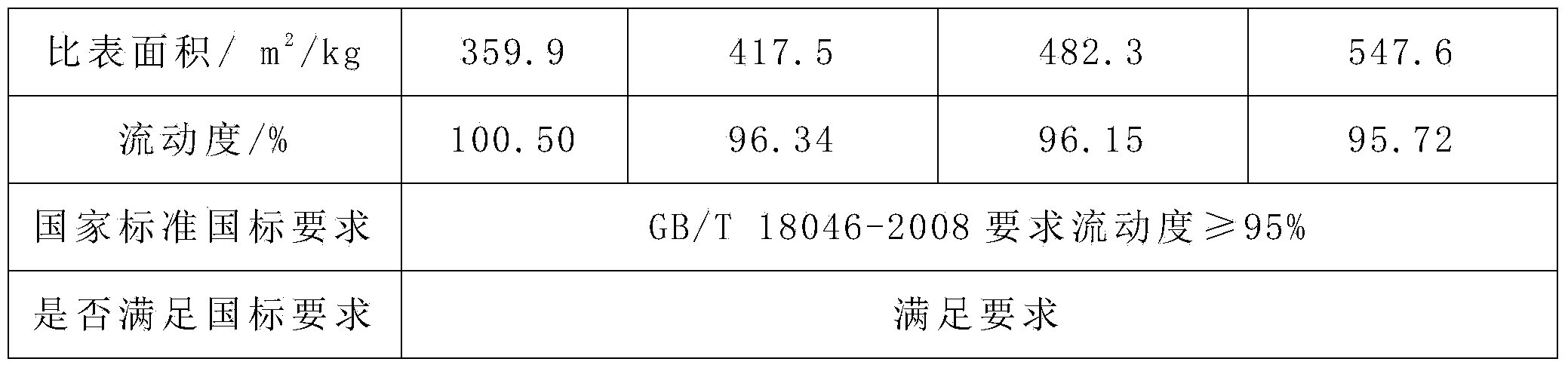

[0052] 1.2 Fluidity test

[0053] According to the method specified in GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete", the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com