Preparation method of rare-earth colorant

A colorant and rare earth technology, applied in the field of preparation of rare earth colorants, can solve problems such as unfavorable safe production, and achieve the effects of low cost, easy industrial production and safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a preparation method of a rare earth colorant, comprising:

[0029] The rare earth coloring agent is obtained by reacting rare earth compound, sulfur and solid carbon in a closed reactor at 1000-1500 DEG C, and the rare earth compound is rare earth carbonate or rare earth oxide.

[0030] In the present invention, the rare earth carbonate is preferably cerium carbonate, lanthanum carbonate or praseodymium carbonate, and the rare earth oxide is preferably ceria, lanthanum trioxide or praseodymium trioxide.

[0031] The present invention uses sulfur and solid carbon as vulcanizing agents, and the sulfur and solid carbon react at high temperature to generate carbon disulfide, and its chemical reaction formula is as follows:

[0032] C+S→CS 2 (carbon disulfide)

[0033] The carbon disulfide produced by the sulfur and solid carbon reacts with the rare earth carbonate or rare earth oxide to form rare earth sulfide. The solid carbon used in the presen...

Embodiment 1

[0043]0.375 moles of sublimated sulfur, 0.25 moles of cerium oxide, 0.00375 moles of anhydrous sodium carbonate, and 12.5 moles of graphite were reacted in a closed crucible at 1000° C. for 5 hours to obtain a reaction product;

[0044] The reaction product is ground, washed with water, and dried to obtain the red rare earth colorant Ce 2 S 3 .

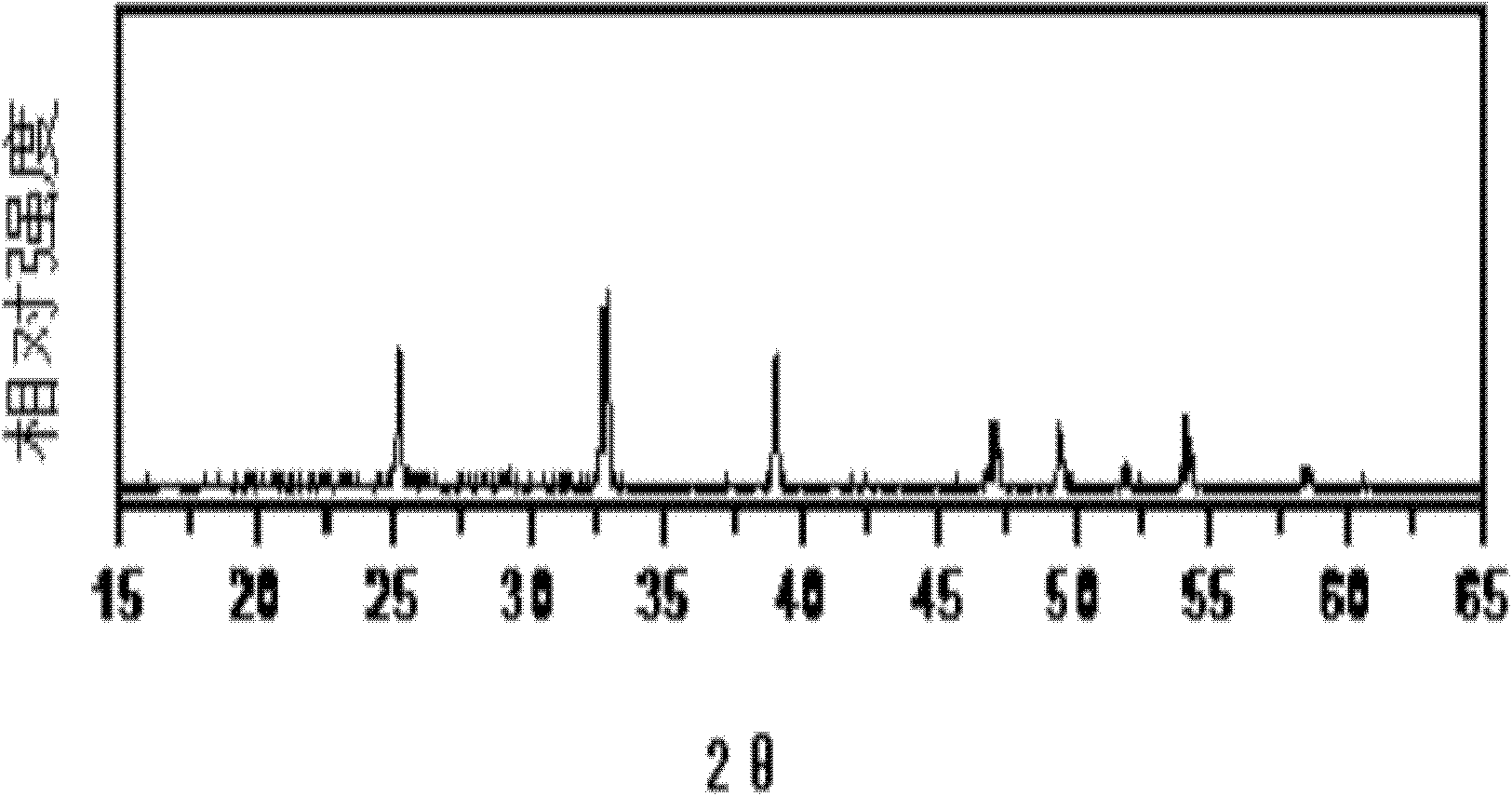

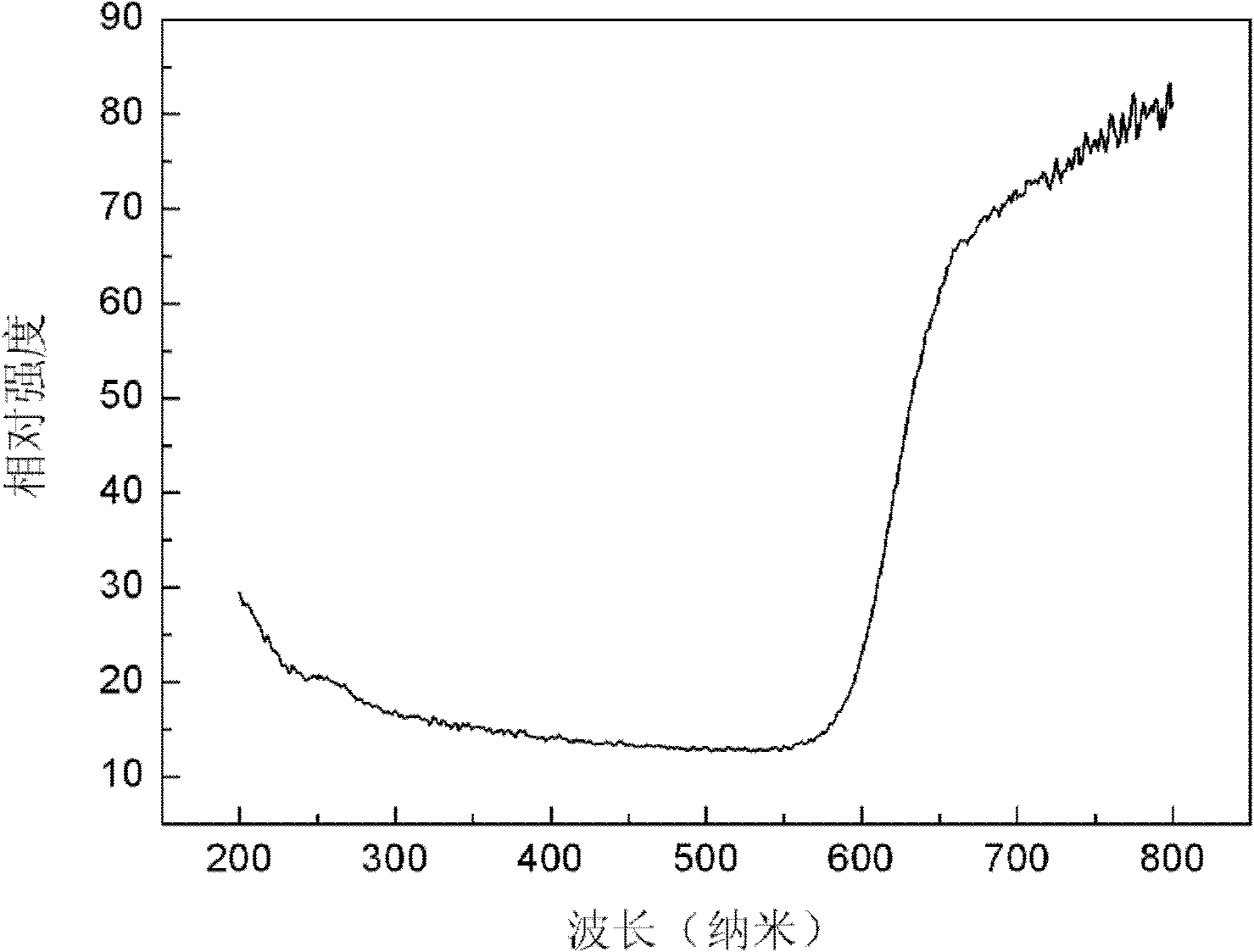

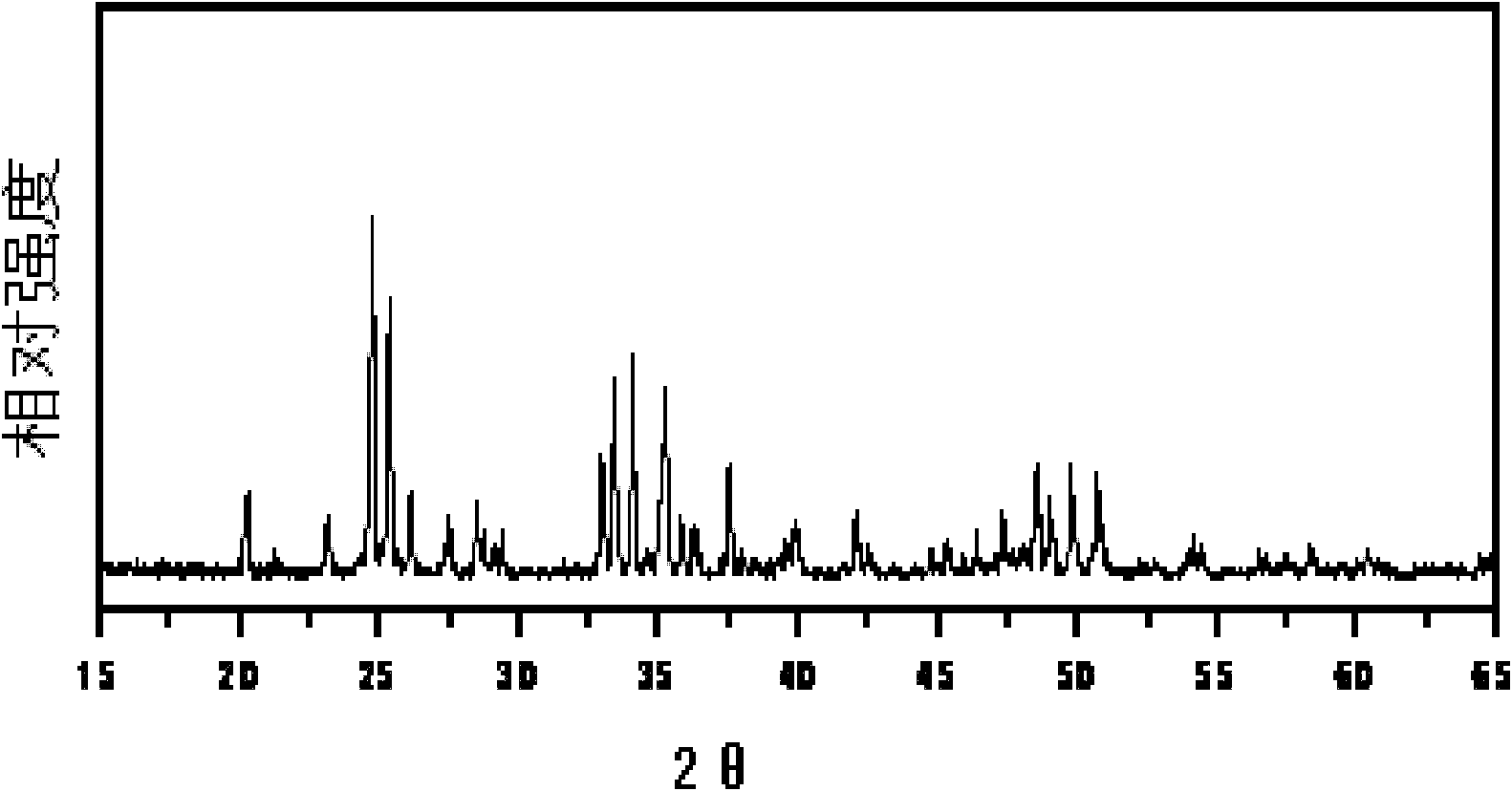

[0045] The chromaticity coordinates of the rare earth colorant prepared in this embodiment are (L*=38, a*=55, b*=40), and the X-ray diffraction spectrum of the rare earth colorant is as follows: figure 1 As shown, the diffuse reflectance spectrum as figure 2 shown.

Embodiment 2

[0047] React 1 mole of sublimed sulfur, 0.25 moles of ceria, 0.075 moles of anhydrous sodium carbonate, and 0.75 moles of graphite in a closed crucible at 1200°C for 1 hour to obtain a reaction product;

[0048] The reaction product is ground, washed with water, and dried to obtain the red rare earth colorant Ce 2 S 3 .

[0049] The chromaticity coordinates of the rare earth colorant prepared in this example are (L*=38, a*=55, b*=40).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com