Method for preparing Ln2O3:RE<3+> and Ln2O3:RE<3+>@SiO2 monodisperse rare earth nano particles

A nanoparticle, monodisperse technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effect of simple method, long fluorescence lifetime and reliable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

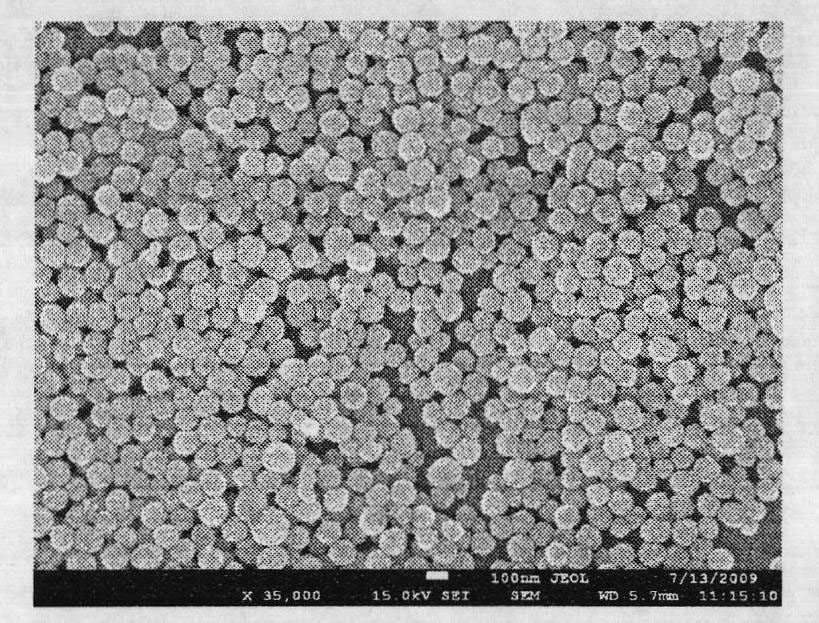

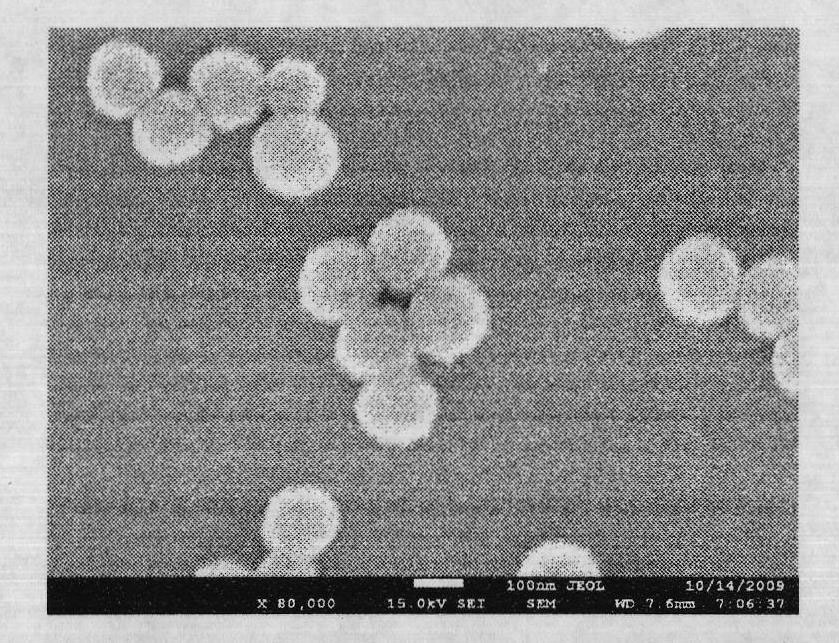

[0026] The preparation process of monodisperse rare earth oxide nanoparticles is as follows, which is divided into two steps:

[0027] 1. Synthesis of Gd(OH) 3 :Eu 3+ Nanospheres:

[0028] Add 0.2 g of Gd(NO 3 ) 3 ·5H 2 O powder, 0.01 g Eu(NO 3 ) 3 ·5H 2 O, 0.504 g CTAB and 0.0032 g FeCl 6H 2 O, so that the molar ratio is 1.0Gd(NO 3 ) 3 ·5H 2 O: 0.05Eu(NO 3 ) 3 ·5H 2 O: 3CTAB: 0.025FeCl 3 ·6H 2 O, stir for 30 minutes to make it evenly mixed; then add 0.2 g of PVP at one time, stop stirring for 12 hours, put it into the reaction kettle, and crystallize at 180°C to obtain monodisperse particles with a diameter of about 100 nanometers Gd(OH) 3 :Eu 3+ Nanospheres; Gd(OH) can be obtained by drying at 60°C after washing by centrifugation 3 :Eu 3+ Nanosphere samples;

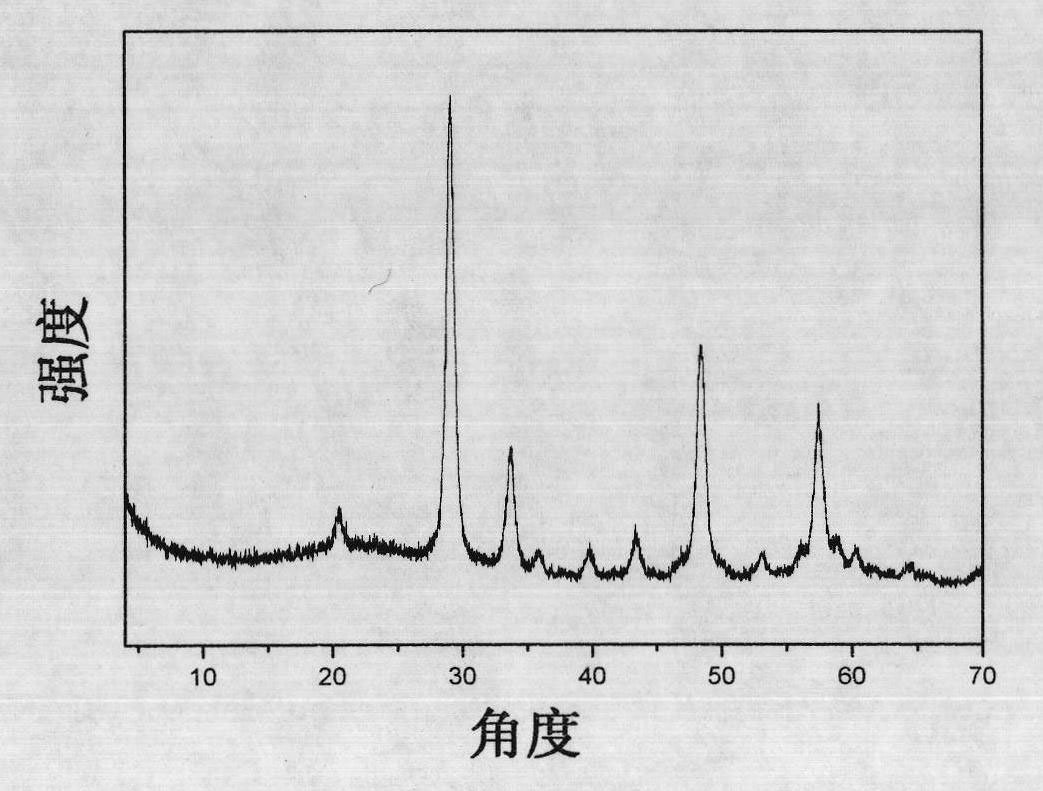

[0029] 2. Gd 2 o 3 :Eu 3+ Synthesis

[0030] Gd(OH) prepared by step 1 3 :Eu 3+ Nanospheres were annealed in a muffle furnace at 550°C for 4 hours to make the Gd(OH) 3 :Eu 3+ Nanosphere Nan...

Embodiment 2

[0032] The preparation process of monodisperse rare earth oxide nano-luminescent materials is as follows, which is divided into two steps:

[0033] 1. Synthesis of La(OH) 3 :Eu 3+ Nanospheres:

[0034] Add 0.19 g La(NO 3 ) 3 ·5H 2 O powder, 0.01 g Eu(NO 3 ) 3 ·5H 2 O, 0.504 g CTAB and 0.0032 g FeCl 3 ·6H 2 O, so that its molar ratio is 1.0La(NO 3 ) 3 ·5H 2 O: 0.05Eu(NO 3 ) 3 ·5H 2 O: 3CTAB: 0.025FeCl 3 ·6H 2 O, stirred for 30 minutes to make it evenly mixed; then added 0.2 g of PVP at one time, stopped after 12 hours of stirring, put it into the reaction kettle, and internally crystallized at 180 ° C to obtain a single crystal with a diameter of about 100 nanometers. Disperse La(OH) 3 :Eu 3+ Nanospheres; La(OH) can be obtained by drying at 60°C after washing by centrifugation 3 :Eu 3+ sample;

[0035] 2. La 2 o 3 :Eu 3+ Synthesis

[0036] La(OH) prepared by step 1 3 :Eu 3+ Nanospheres were annealed in a muffle furnace at 550°C for 4 hours to make La...

Embodiment 3

[0038] The preparation process of monodisperse rare earth oxide nano-luminescent materials is as follows, which is divided into two steps:

[0039] 1. Synthesis of Y(OH) 3 :Eu 3+ Nanospheres:

[0040] Add 0.24 g of Y(NO 3 ) 3 ·5H 2 O powder, 0.01 g Eu(NO 3 ) 3 ·5H 2 O, 0.504 g CTAB and 0.0056 g AgNO 3 , so that the molar ratio is 1.0Y(NO 3 ) 3 ·5H 2 O: 0.05Eu(NO 3 ) 3 ·5H 2 O: 3CTAB: 0.05AgNO 3 , stirred for 30 minutes to make it evenly mixed; then added 0.2 g of PVP at one time, stopped after 12 hours of stirring, put it into the reaction kettle, and crystallized at 180°C to obtain a monodisperse Y with a diameter of about 100 nanometers. (OH) 3 :Eu 3+ Nanospheres; Y(OH) can be obtained by drying at 60°C after centrifugal washing 3 :Eu 3+ sample;

[0041] 2. Y 2 o 3 :Eu 3+ Synthesis

[0042] Y(OH) prepared by step 1 3 :Eu 3+ Nanospheres were annealed in a muffle furnace at 550°C for 4 hours to make Y(OH) 3 :Eu 3+ Nanospheres Nanospheres transform i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com