Multiphase transparent ceramic, multiphase transparent ceramic optical fiber and preparation method and application of multiphase transparent ceramic

A technology for transparent ceramics and optical fibers, applied in the field of multiphase transparent ceramic optical fibers and their preparation, and multiphase transparent ceramics, achieving the effects of simple preparation process, low equipment requirements, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

[0057] (1) Weigh the following component raw materials according to the following molar percentages: 25% SiO 2 , 25% BaCO 3 , 25% Al 2 o 3 , 24.5% LaF 3 , 0.5% Eu 2 o 3 Then fully grind with an agate mortar for 15 minutes;

[0058] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1500° C. for 30 minutes, and melt them to obtain molten glass;

[0059] (3) Pour molten glass into the formwork for cooling and forming to obtain a transparent glass block;

[0060] (4) Quickly transfer the glass to a muffle furnace, and anneal at 500°C for 48 hours to obtain a precursor glass;

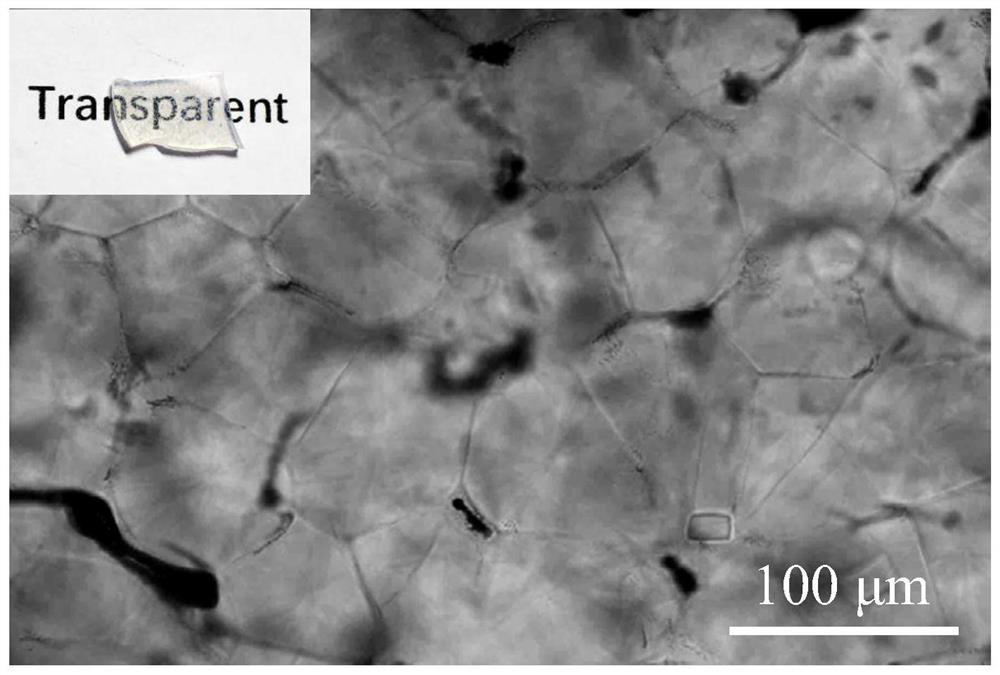

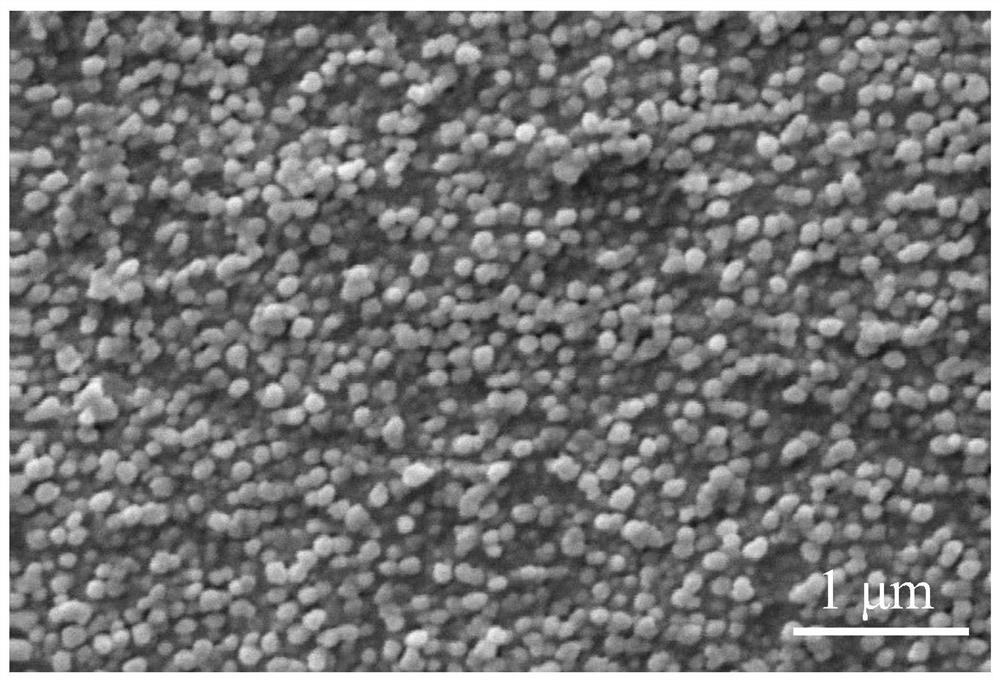

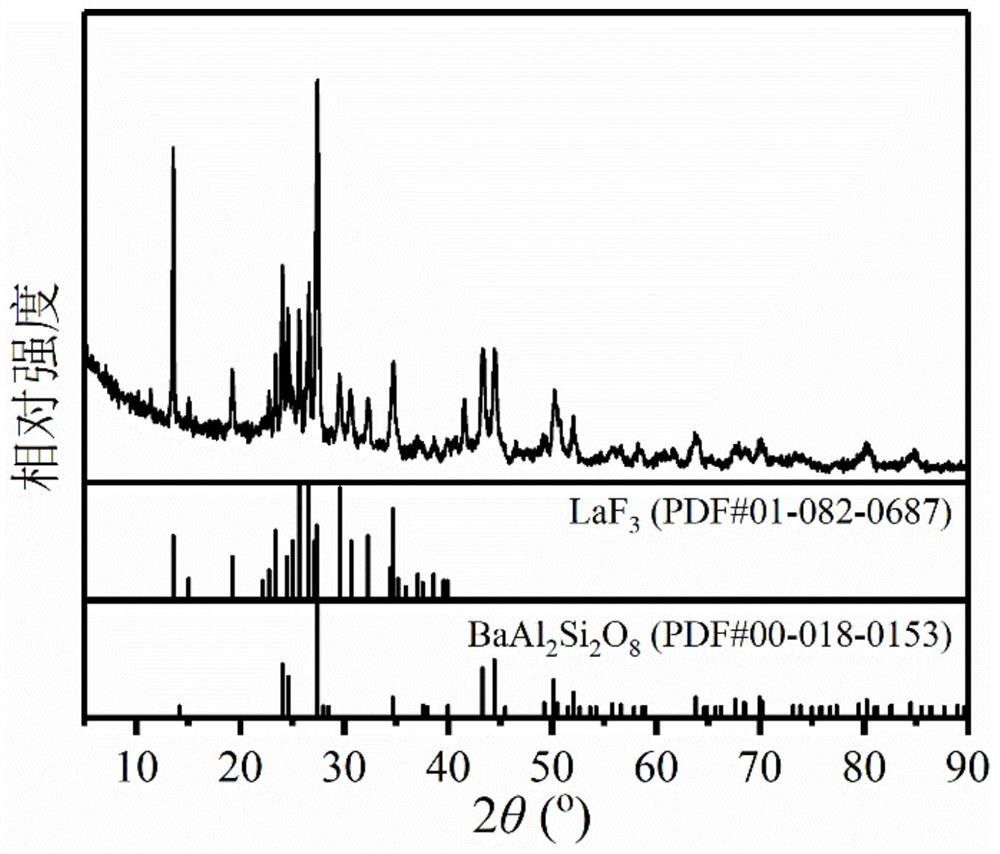

[0061] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 830°C, hold the temperature for 4 hours, and take it out after returning to room temperatur...

Embodiment 2

[0074] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

[0075] (1) Weigh the following component raw materials according to the following mole percentage: 30% SiO 2 , 20% BaCO 3 , 30% Al 2 o 3 , 19.9% GdF 3 , 0.1% Eu 2 o 3 Then fully grind it with an agate mortar for 25 minutes;

[0076] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1550° C. for 60 minutes, and heat them for 60 minutes to melt to obtain a glass melt;

[0077] (3) Pour molten glass into the formwork for rapid cooling and forming to obtain a transparent glass block;

[0078] (4) Quickly transfer the glass to a muffle furnace, and anneal at 650°C for 96 hours to obtain a precursor glass;

[0079] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 790°C, hold the temperature for 2 hours, and take it out af...

Embodiment 3

[0090] A preparation method of multiphase transparent ceramics, the preparation steps are as follows:

[0091] (1) Weigh the following component raw materials according to the following molar percentages: 40% SiO 2 , 20% BaCO 3 , 25%Al 2 o 3 , 14% BaF 2 , 1% Eu 2 o 3 Then fully grind it with an agate mortar for 25 minutes;

[0092] (2) Put the uniformly mixed raw materials into an alumina crucible, place them in a high-temperature box furnace at 1500°C for 20 minutes, and heat them for 20 minutes to melt to obtain a molten glass;

[0093] (3) Pour molten glass into the formwork for cooling and forming to obtain a transparent glass block;

[0094] (4) Quickly transfer the glass to a muffle furnace, and anneal at 550°C for 96 hours to obtain a precursor glass;

[0095] (5) Cut the precursor glass into the desired size, place it in a muffle furnace for heat treatment, the crystallization temperature is 800°C, the holding time is 2.5h, and take it out after returning to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com