Sandwich type transparent conductive film and preparation method thereof

A transparent conductive film, sandwich-type technology, applied in chemical instruments and methods, ion implantation plating, gaseous chemical plating, etc., can solve problems such as reducing device performance, and achieve improved device stability The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

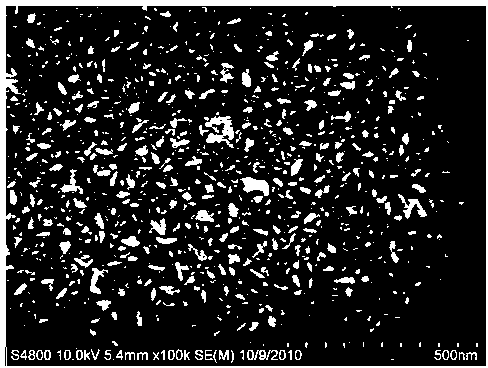

Image

Examples

Embodiment 1

[0028] The reaction chamber is evacuated to a low vacuum below 20 hPa with a vacuum pump and heated to 200° C., and then the reaction chamber is cleaned with high-purity nitrogen with a purity of 5N. Put the cleaned quartz glass substrate into the reaction chamber. The diethylzinc precursor is pulsed into the reaction chamber with high-purity nitrogen gas for 0.1s, chemically adsorbed onto the substrate, and then pulsed with pure nitrogen gas for 3s to clean the substrate physically adsorbed and excess in the reaction chamber. Diethyl zinc precursor; then a 0.2s water vapor pulse is introduced to react surface chemically with the previously chemisorbed diethyl zinc, and then a 4s high-purity nitrogen pulse is used to clean off excess water vapor. 500 cycles are completed in this way, and the thickness of the obtained zinc oxide film is about 100 nm. Put the quartz glass substrate deposited with the zinc oxide film into the sputtering reaction chamber, pump the vacuum to above...

Embodiment 2

[0030] The reaction chamber is evacuated to a low vacuum below 20 hPa with a vacuum pump and heated to 200° C., and then the reaction chamber is cleaned with high-purity nitrogen with a purity of 5N. Put the cleaned quartz glass substrate into the reaction chamber. The diethylzinc precursor is pulsed into the reaction chamber with high-purity nitrogen gas for 0.1s, chemically adsorbed onto the substrate, and then pulsed with pure nitrogen gas for 3s to clean the substrate physically adsorbed and excess in the reaction chamber. Diethyl zinc precursor; then a 0.2s water vapor pulse is introduced to react surface chemically with the previously chemisorbed diethyl zinc, and then a 4s high-purity nitrogen pulse is used to clean off excess water vapor. 500 cycles are completed in this way, and the thickness of the obtained zinc oxide film is about 100 nm. Put the quartz glass substrate deposited with the zinc oxide film into the sputtering reaction chamber, pump the vacuum to above...

Embodiment 3

[0032]The reaction chamber is evacuated to a low vacuum below 20 hPa with a vacuum pump and heated to 200° C., and then the reaction chamber is cleaned with high-purity nitrogen with a purity of 5N. Put the cleaned quartz glass substrate into the reaction chamber. The diethylzinc precursor is pulsed into the reaction chamber with high-purity nitrogen gas for 0.1s, chemically adsorbed onto the substrate, and then pulsed with pure nitrogen gas for 3s to clean the substrate physically adsorbed and excess in the reaction chamber. Diethyl zinc precursor; then a 0.2s water vapor pulse is introduced to react surface chemically with the previously chemisorbed diethyl zinc, and then a 4s high-purity nitrogen pulse is used to clean off excess water vapor. 500 cycles are completed in this way, and the thickness of the obtained zinc oxide film is about 100 nm. Put the quartz glass substrate deposited with the zinc oxide film into the sputtering reaction chamber, pump the vacuum to above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com