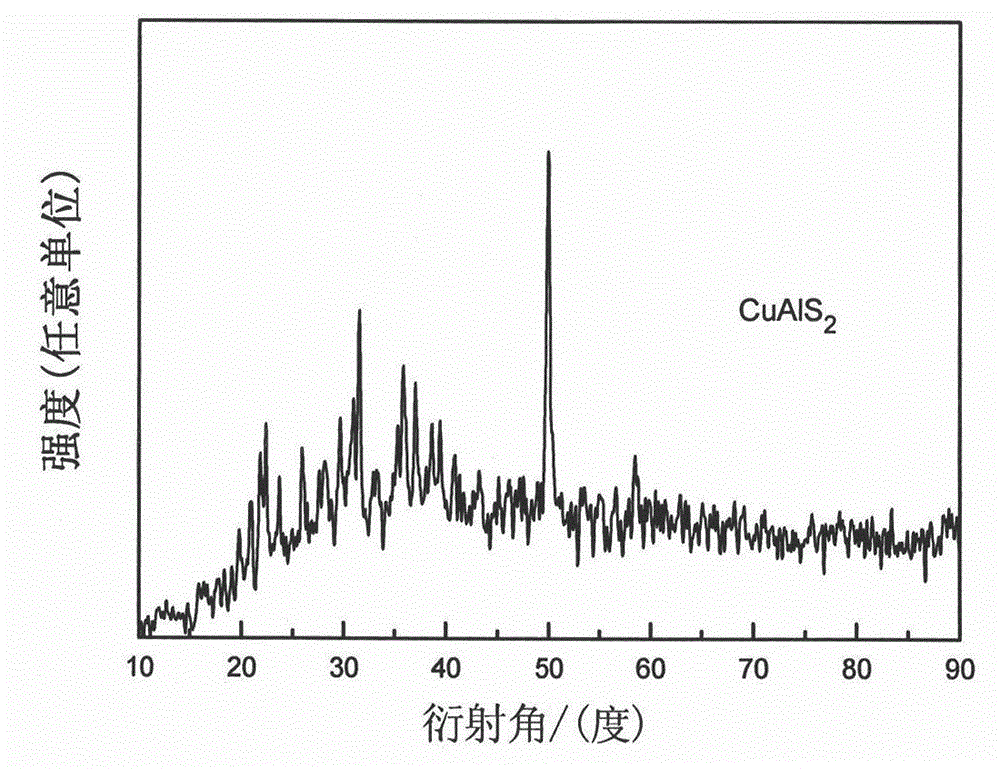

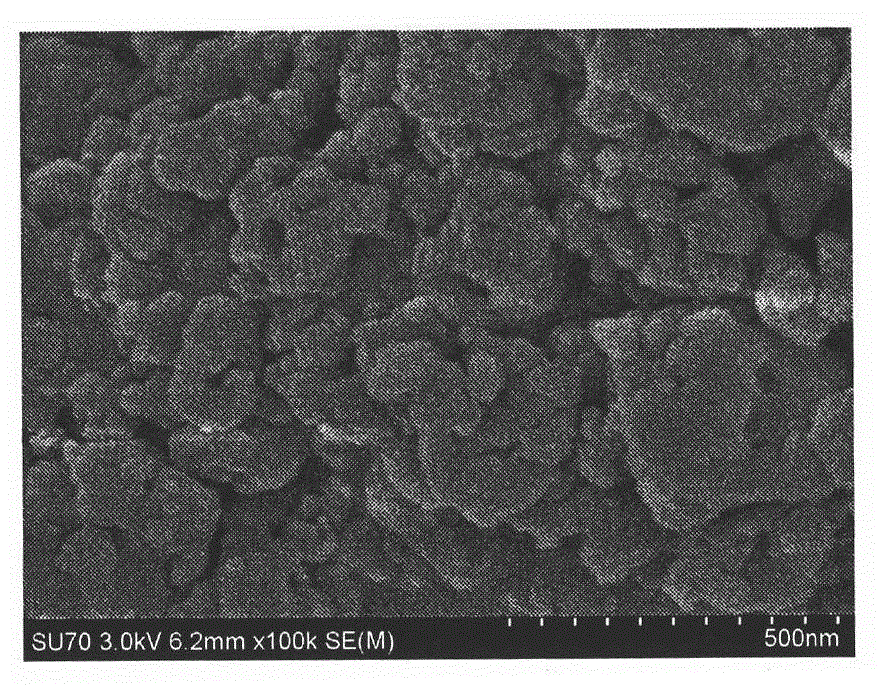

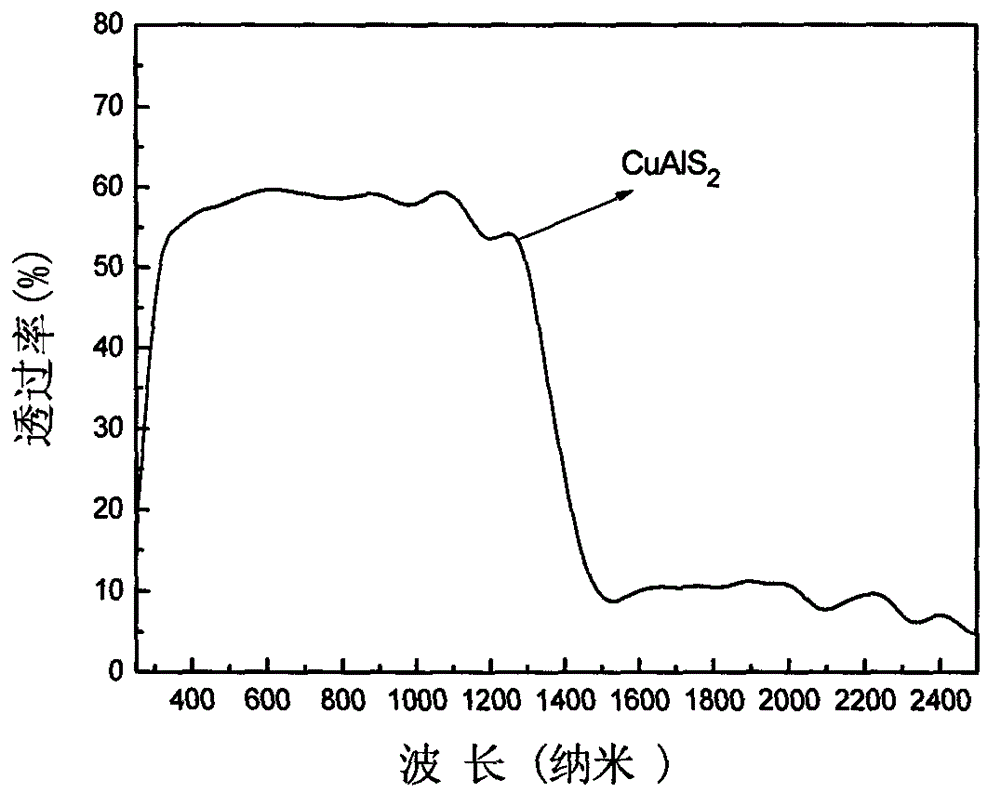

Isolation film containing nano copper-aluminum sulfide and preparation method thereof

A technology of nano-copper aluminum sulfide and isolated film, which is applied in the field of solar heat insulation materials, can solve problems such as complex manufacturing process, inability to form independent film, visible light pollution, etc., and achieve the effect of low production cost, rich energy level structure and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve copper nitrate and aluminum nitrate in deionized water to form a mixed solution of copper nitrate and aluminum nitrate with a concentration of 0.10 mol / liter of copper nitrate / aluminum nitrate, and prepare a solution of sodium sulfide with a concentration of 0.20 mol / liter of sodium sulfide. or ammonia water to adjust the pH value of copper nitrate / aluminum nitrate mixed solution and sodium sulfide solution to 6-8 for later use; put 2 liters of copper nitrate / aluminum nitrate mixed solution into the spray container of ultrasonic atomization device, and put 4 liters of sodium sulfide The solution is packed into the reaction barrel of the ultrasonic atomization device, the surface area of the sodium sulfide solution in the reaction barrel is 30 square centimeters (can be 18 square centimeters, 50 square centimeters, etc.), the ultrasonic power is 20W, the frequency is 50KHz, the ultrasonic spray head At an internal liquid flow rate of 100 ml / hour, the copper nit...

Embodiment 2

[0022] It is basically the same as Example 1, except that butyl titanate and MTES are mixed in a molar ratio of 1:4.

Embodiment 3

[0024] It is basically the same as Example 1, except that butyl titanate and MTES are mixed in a molar ratio of 1:19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com