Process for producing bamboo fiber

A production process, bamboo fiber technology, applied in the chemical post-processing of fibers, fiber processing, manufacturing tools, etc., can solve the problems of high-efficiency large-scale production of bamboo processing, thick fibers, and low production efficiency, and achieve high-efficiency large-scale production. Production problems, high resource utilization, and the effect of reliable production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

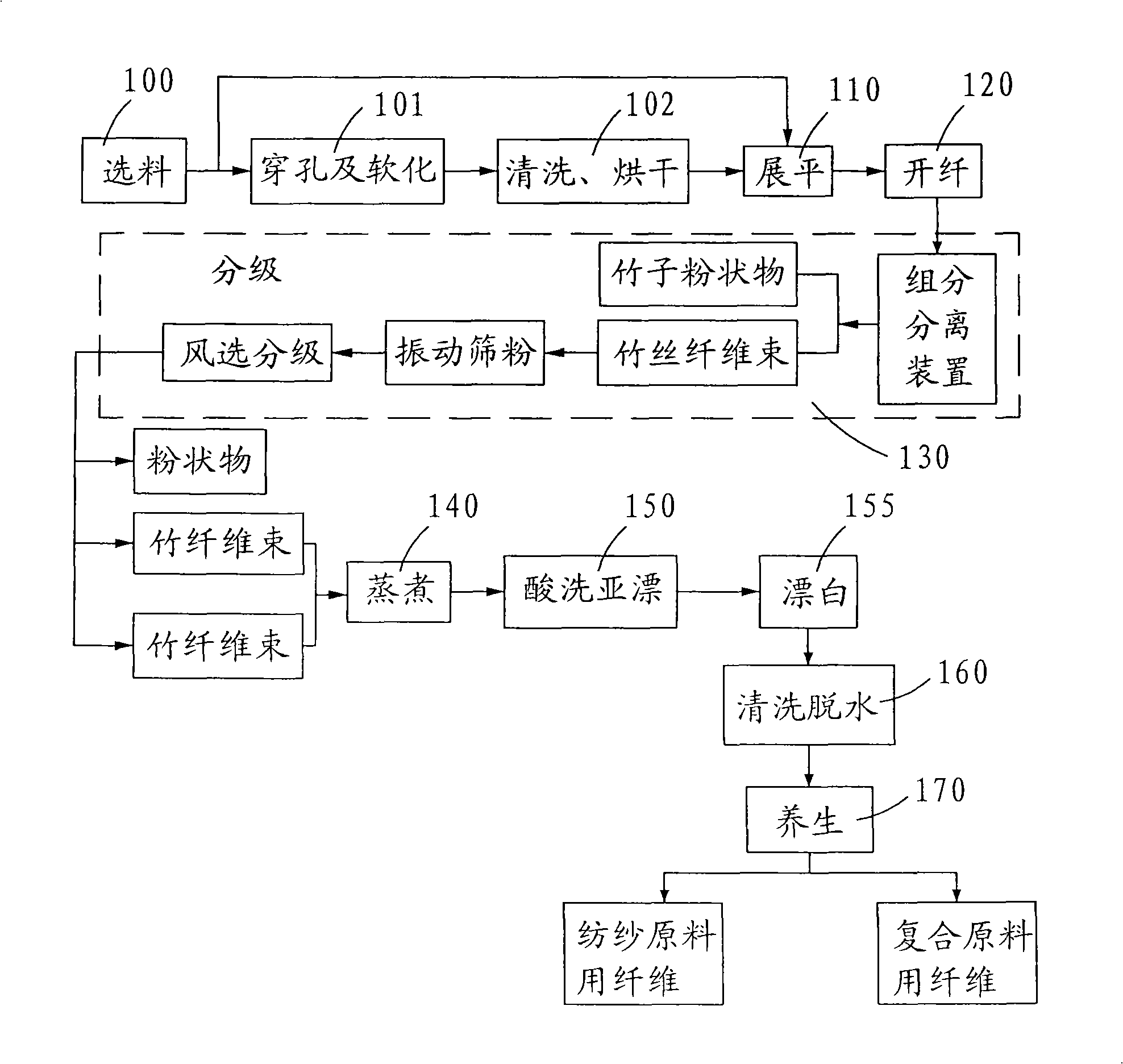

Image

Examples

Embodiment 1

[0039] Step 10: Choose three-year-old moso bamboo or Ci bamboo or green bamboo or Ma bamboo or Qingpi bamboo and other bamboo materials.

[0040] Step 11: Perforate with a perforator or other methods, or cut the cylindrical bamboo into two halves with a machine tool, so that the bamboo becomes a hollow cylindrical (conical) tube shape or a semi-cylindrical (conical) tube shape, so that the softening liquid enters the bamboo Inside the cavity, sodium hydroxide in the softening solution: 80g / l, sodium carbonate 180g / l, sodium sulfite 45g / l, sodium silicate 45g / l or waste alkali solution (alkali content 12%), and completely immerse the bamboo in In the softening solution, place it at room temperature for 15 days, or heat it to 90-100°C and keep it warm for 1-5 hours.

[0041] Step 12: Soak the softened bamboo in the designated cleaning pool for 15 minutes, then rinse and send it to the area to be processed to dry, then send the dried bamboo to the continuous mechanical processing...

Embodiment 2

[0051] Step 30: Choose bamboo materials such as annual Moso bamboo or Ci bamboo or green bamboo or Ma bamboo or green bamboo.

[0052] Step 33: Send directly to the continuous mechanical processing area, through heating and baking or without heating and baking, and send it to the flattening area with the help of feeding force, using a special mold to split the lower edge of the front end of the bamboo first and then gradually flatten.

[0053] Step 34: After the bamboo is flattened, it is combed, and then the bamboo is formed into a fiber bundle by a fiber-opening separator.

[0054] Step 35: After airflow classification, the bamboo tow fibers are further classified by vibrating conveyor belt and winnowing grading system to remove ultra-short fibers and powder particles to obtain bamboo fiber bundles with uniform length and fineness.

[0055] Step 36: Put the bundle of fibers in a cooking pot (pool) and heat for 60 minutes. The temperature during scouring is 70° C., the bath r...

Embodiment 3

[0061] Step 50: Select two to five-year-old moso bamboo or citron bamboo or green bamboo or hemp bamboo or green bamboo and other bamboo materials.

[0062] Step 51: Use a perforator or other methods to perforate the bamboo into a hollow cylindrical (conical) shape, so that the softening liquid can enter the bamboo cavity. The softening liquid is the spent scouring liquid used in Embodiment 1 and Embodiment 2. , or the scouring solution used in step 56 of the present embodiment, or the mixed solution of the two above, etc., and the bamboo is completely immersed in the softening solution, placed at room temperature for a certain period of time (60 days) or heated to 90~100 ° C, Keep warm for 5 hours.

[0063] Step 52: Soak the softened bamboo in a designated cleaning pool for 15 minutes, then rinse and send it to the area to be processed to dry, then send the dried bamboo to the continuous mechanical processing area for processing, and then heat and bake.

[0064] Step 53: Sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com