Wet-type rotary vane electric vacuum pump for automobile

An electric vacuum pump, wet technology, applied in the direction of rotary piston/swing piston pump components, rotary piston pumps, components of pumping devices for elastic fluids, etc., can solve the problem of limited pumping rate of vacuum pumps Meet the requirements, affect the braking effect of the vehicle, etc., and achieve the effect of compact structure, light weight and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

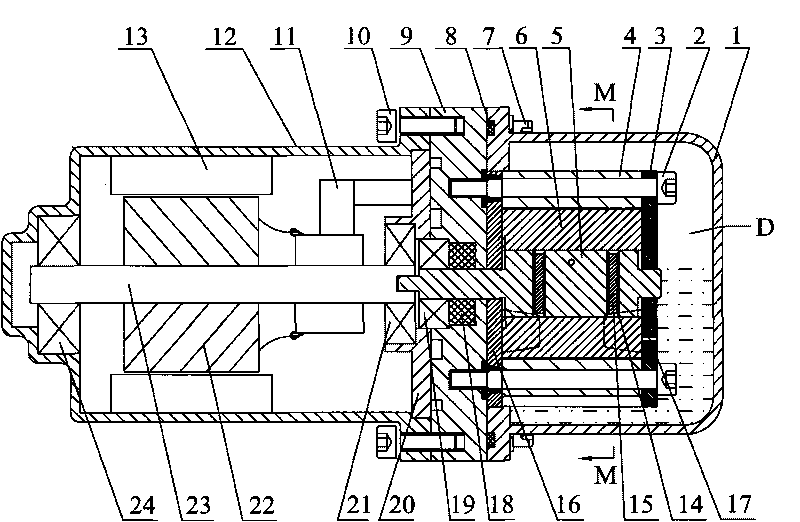

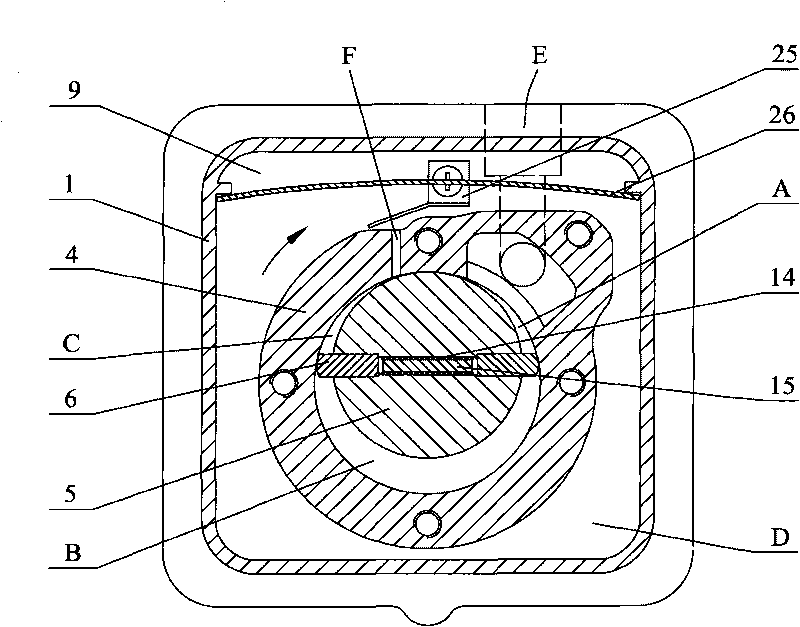

[0020] Such as Figure 1 to Figure 3 As shown, it is a wet rotary vane electric vacuum pump for automobiles according to the present invention, which includes a fixedly connected motor assembly and a pump body assembly. The motor assembly includes a fixedly connected shell 12 and a sealing end cover 20, and the inner wall of the shell 12 is fixedly connected The ring-shaped permanent magnet stator 13 is provided with a coil 22 inside the ring-shaped permanent magnet stator 13, and the center of the coil 22 is fixedly connected with a motor shaft 23, one end of the motor shaft 23 is connected to the casing 12, and the other end of the motor shaft 23 is connected to the sealing end On the cover 20, the motor shaft 23 is connected to the sealing end cover 20 and the casing 12 respectively through the bearing I 21 and the bearing II 24, and the motor shaft 23 is provided with a brush 11 connected to the coil 22. The pump body assembly includes a fixedly connected rear end cover 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com