Device and method for scalding slaughtered poultry

A poultry and tank washing technology, applied in the field of scalding medium, can solve problems such as difficult equipment cleaning, skin and meat damage, heat loss on the surface of scalding medium, etc., and achieve the effect of simplifying maintenance and preventing the risk of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

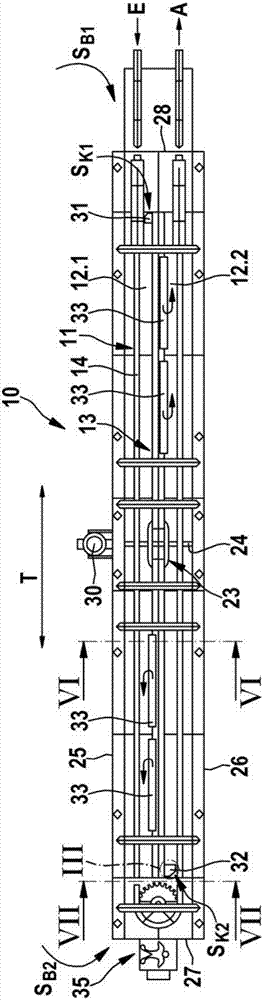

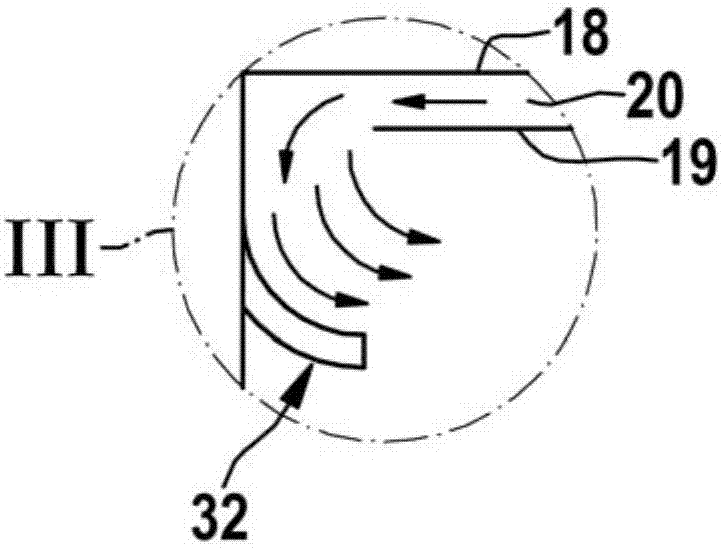

[0037] The equipment shown in the figure is used to scald upside down chickens, and transfer the chickens to a scalding tank with a high water level scalding medium, so that the chickens are completely immersed under the surface of the scalding medium, so that The chicken is covered with the scalding medium held in the conveying line and the scalding medium flowing from the upper side and the end side of the channel. Obviously, the water level of the scalding medium can be relatively low, so that the chicken is not immersed or partially submerged in the scalding medium at all, for example, up to the neck of the chicken, so that the chicken is exclusively or completely covered with the water flowing upward from the channel. Scald the medium. The present invention can be correspondingly applied to birds such as turkeys, ducks, geese and waterfowls.

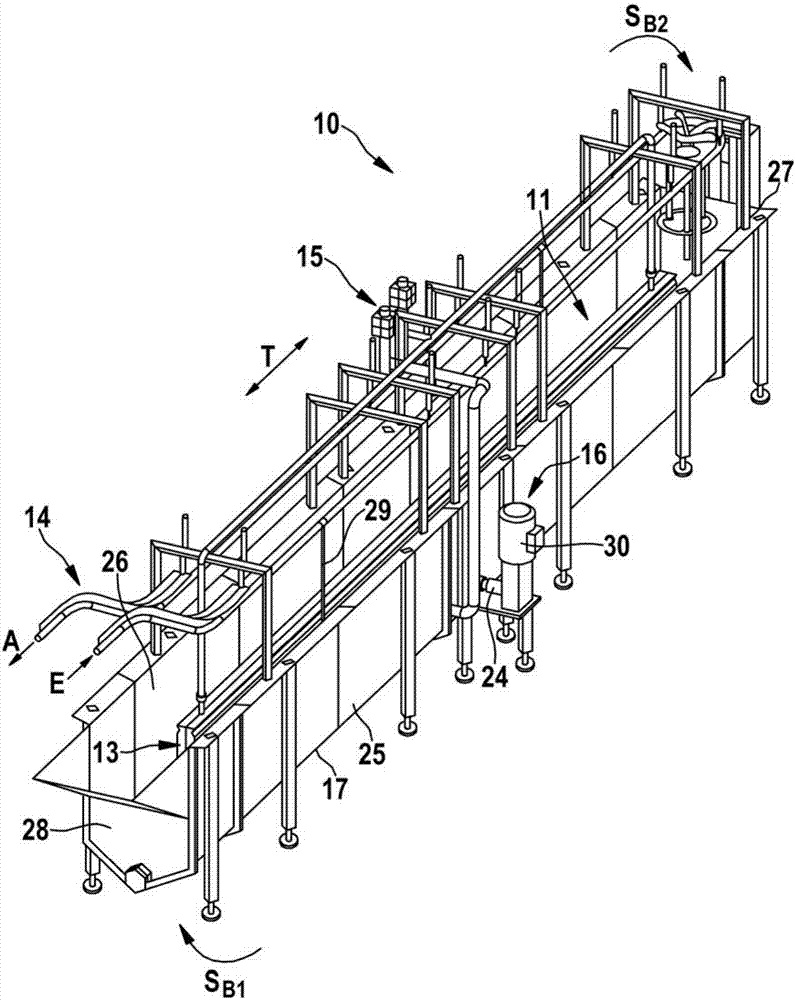

[0038] figure 1 A device 10 constructed and designed for scalding slaughtered birds G is shown. The device 10 includes a linear sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com