Gas displacement method air conditioner vacuum pumping device and vacuum pumping method

A gas replacement method and a technology of a vacuuming device, which are applied in the field of air-conditioning vacuuming, can solve the problems of low vacuuming efficiency and easy residual moisture, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

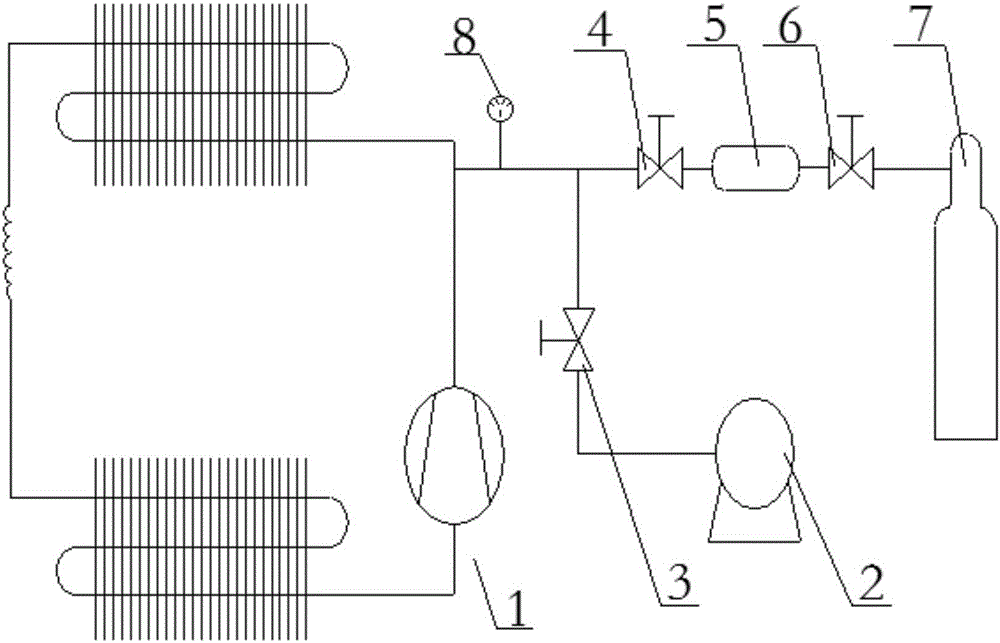

[0037] combine figure 1 , a kind of air-conditioning vacuum pumping device of the gas replacement method of the present embodiment, mainly by vacuum pump 2, gas storage device 5 and gas storage bottle 7, on the pumping pipeline of refrigeration system 1, there are two branch roads, one branch road and vacuum pump 2 connected, and the first control valve 3 is set on the pipeline; the second control valve 4, the gas storage device 5, the third control valve 6, and the gas storage bottle 7 are connected in sequence on the other branch.

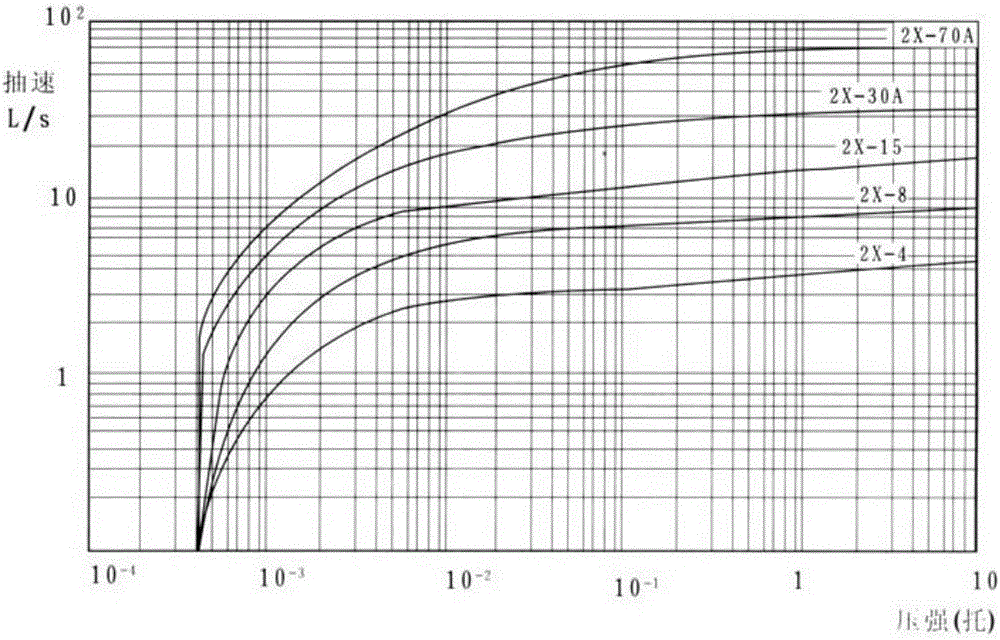

[0038] When vacuuming the refrigeration system, when the ultimate pressure of the vacuum pump performance parameters is reached, the corresponding pumping rate will decrease, and the final vacuuming is more difficult, and it is difficult to completely remove the water vapor. Therefore, the volume of the gas storage device 5 in this embodiment is scientifically designed and calculated according to the performance parameter curves such as the ultim...

Embodiment 2

[0042] The basic structure of the air-conditioning vacuum pumping device by gas replacement method in this embodiment is the same as that of Embodiment 1, the difference is that in order to facilitate the observation of the vacuum degree in the refrigeration system 1, a digital display vacuum gauge is installed on the pumping pipeline. 8. The digital display vacuum gauge 8 can detect the vacuum degree in the refrigeration system 1 in real time, judge according to the measured vacuum degree, and orderly switch and coordinate the three control valves to achieve the purpose of gas replacement and circular vacuuming.

Embodiment 3

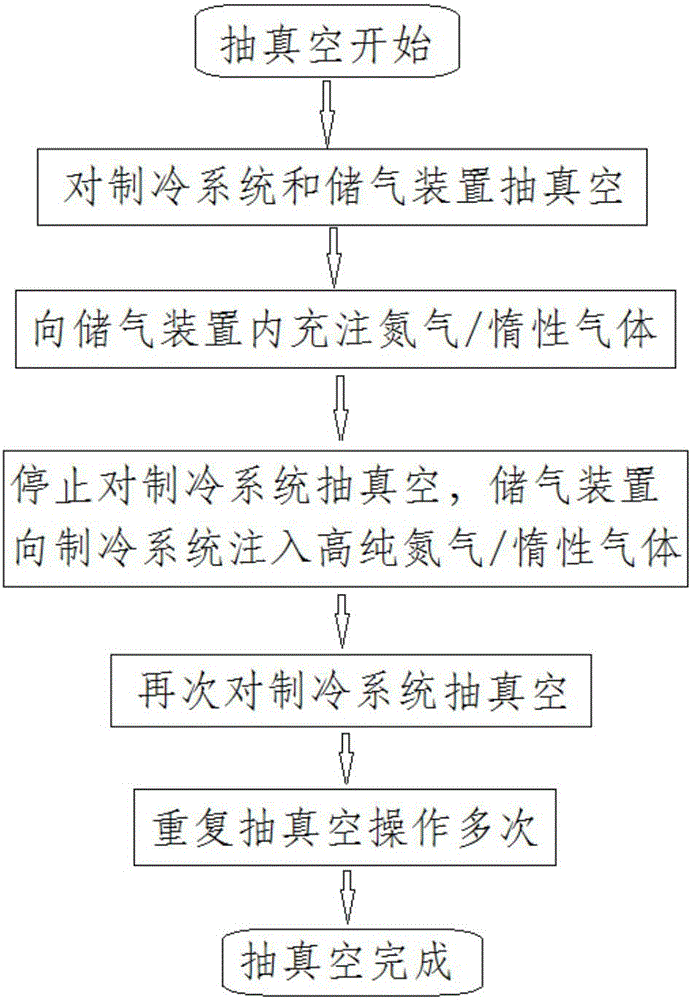

[0044] to combine figure 2 , a kind of air-conditioning vacuum pumping method by gas replacement method in the present embodiment adopts the air-conditioner vacuum pumping device by gas replacement method in the above-mentioned embodiment to carry out vacuum pumping, and high-purity nitrogen is taken as an example for illustration, and the steps are as follows:

[0045] Step 1: open the first control valve 3 and the second control valve 4, and vacuumize the refrigeration system 1 and the gas storage device 5;

[0046] The main purpose of this step is to firstly evacuate the refrigeration system 1 and at the same time evacuate the gas storage device 5, so that the gas storage device 5 can be filled with high-purity nitrogen later.

[0047] Step 2, close the second control valve 4, open the third control valve 6, fill the high-purity nitrogen in the gas storage device 5, and then close the third control valve 6; It is charged into the gas storage device 5 first, and then the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com