Dehydrogenation method for aluminum or aluminum alloy fused mass by using solid-state proton conductor and device thereof

A technology for aluminum alloy melts and proton conductors, applied in the field of dehydrogenation of aluminum or aluminum alloy melts with solid proton conductors and its devices, can solve problems such as the dehydrogenation of metal melts that have not been reported, and achieve industrial production, The effect of simple equipment and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

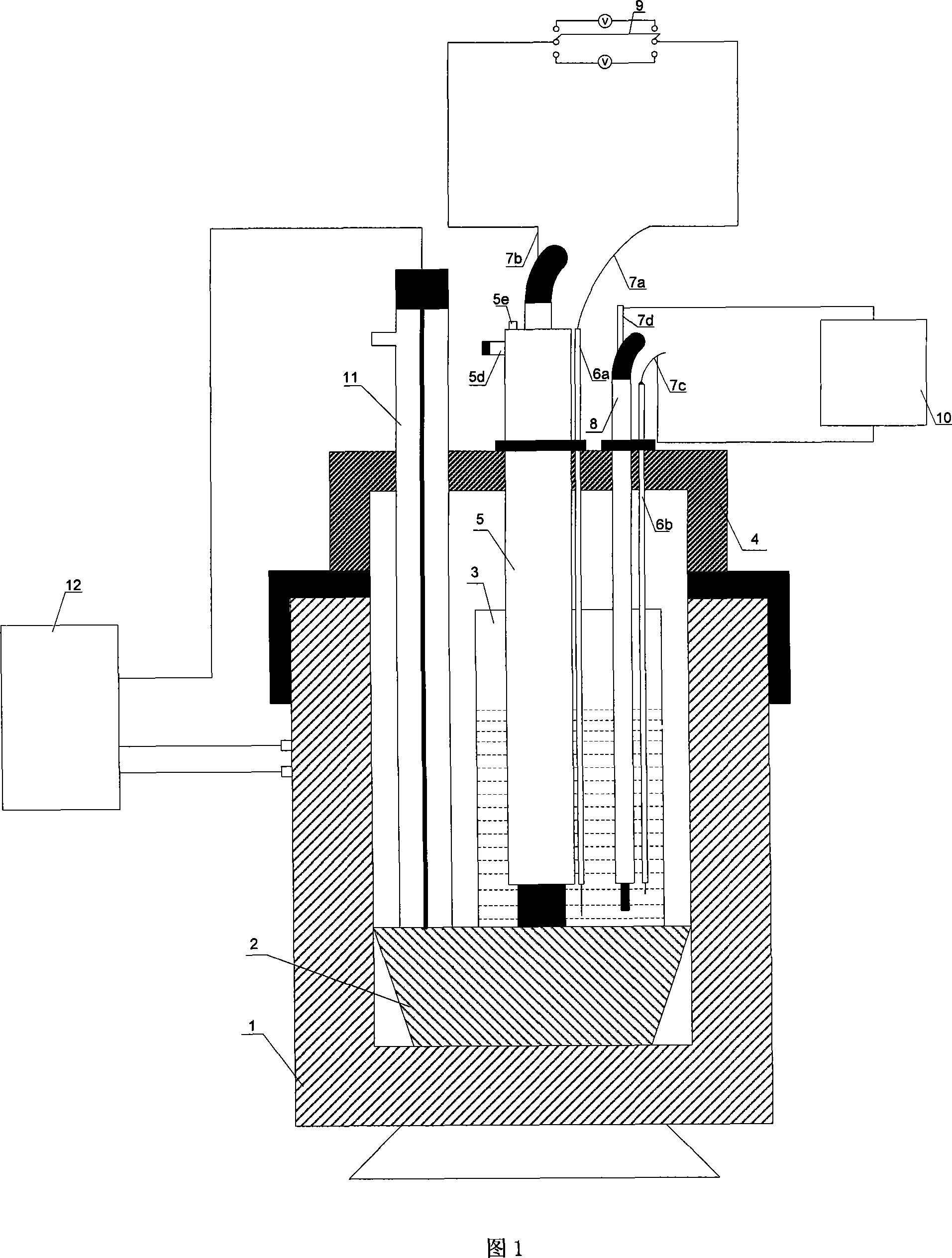

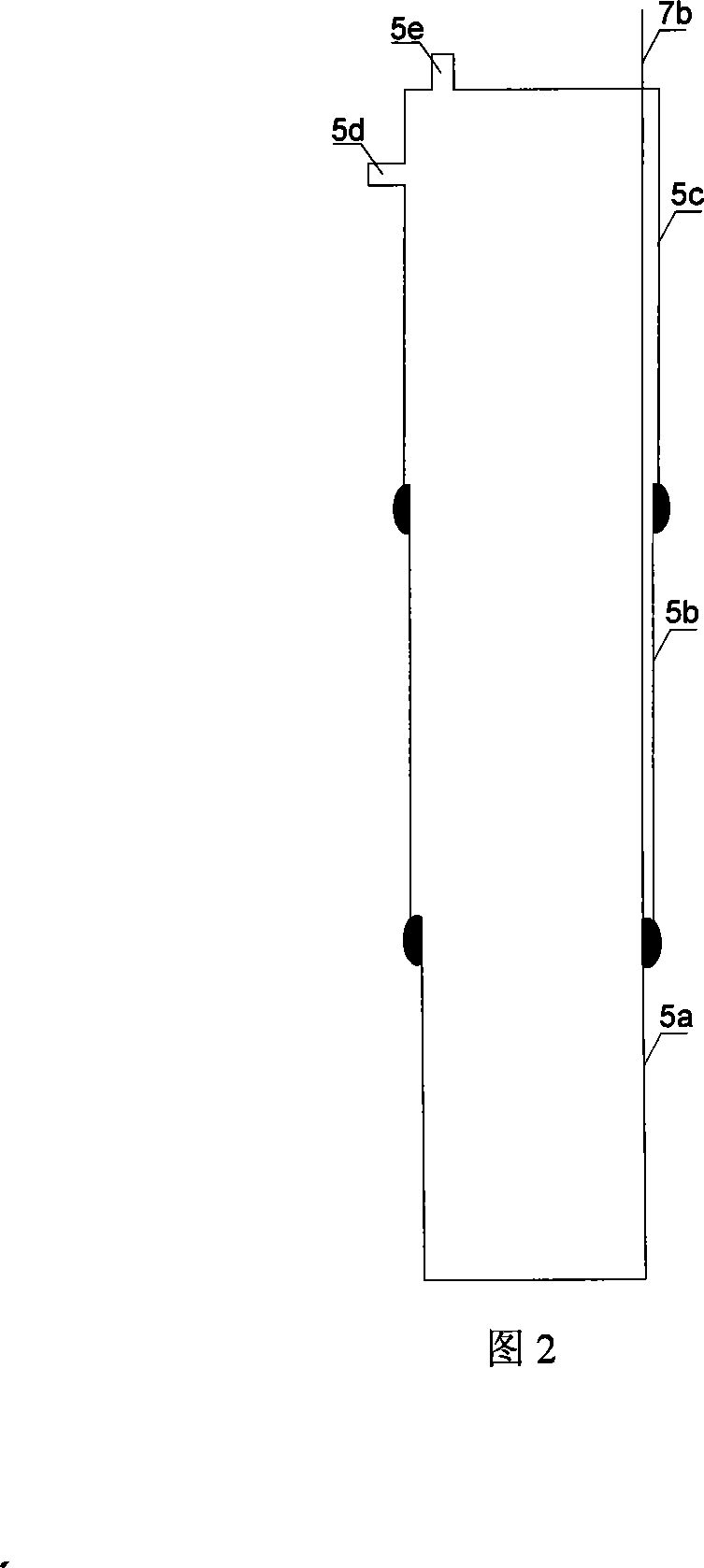

[0026] Example 1: As shown in Figures 1 and 2, a solid-state proton conductor is used to dehydrogenate aluminum or aluminum alloy melts. It is composed of a heating furnace using a resistance wire furnace, and a corundum gasket is installed on the bottom of the furnace. 2. The aluminum melting tank 3 used for melting aluminum or aluminum alloy, choose graphite crucible and put it on the corundum gasket 2, add a graphite cover 4 on the resistance wire furnace, through the hole on the graphite cover 4, put the solid electrolyte The tube 5 and the electrode lead wire 7a with the corundum tube protective sleeve 6a are selected from Ni-Cr wire and inserted into the aluminum melting tank 3, and the electrode lead wire 7b and the electrode lead wire 7a in the solid electrolyte tube 5 are respectively connected to the contacts of the external power switch 9; Hydrogen sensor 8 (being prior art, patent application number is disclosed in 207100117123) and another electrode lead wire 7c th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com