Vacuumizing hole of vacuum glass and manufacturing method thereof

A technology of vacuum glass and air extraction port, which is applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of weakening the air tightness of solder performance, not necessarily good economic benefits, and complicated vacuuming process, etc. Prolonged service life, simple structure, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

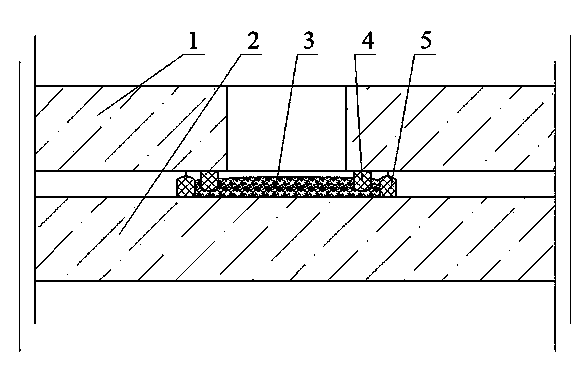

[0061] Embodiment 1: see figure 1 , the vacuum glass is composed of upper glass 1 and lower glass 2, a through hole is drilled on the upper glass 1 to form an air inlet, and the glass is coated or printed on the lower surface of the upper glass 1 and the upper surface of the lower glass 2. Paste or metal paste is printed into a sealing ring concentric with the air suction port, the sealing ring 4 of the upper glass 1 can be inserted into the sealing ring 5 of the lower glass 2, and the air extraction channel is between the two sealing rings; the upper and lower glasses are sent into the Sinter the sealing ring on the upper and lower glass in a high-temperature furnace or tempering furnace, and then use low-temperature glass solder to seal the edges of the combined upper and lower glasses in an atmospheric-pressure high-temperature furnace. After the edge-sealing glass is taken out of the high-temperature furnace, it is Put the metal solder 3 such as tin alloy into the air exha...

Embodiment 2

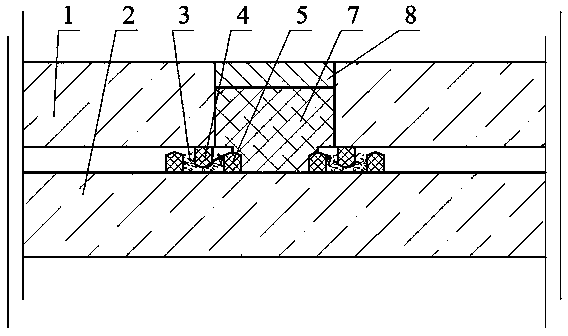

[0062] Example 2: see figure 2 The vacuum glass consists of an upper glass 1 and a lower glass 2. A through hole is drilled on the upper glass 1 to form an air inlet, and glass paste or metal paste is used on the lower surface of the upper glass 1 and the upper surface of the lower glass 2. Bond one or two metal rings or glass rings. When using metal rings, metals with similar thermal expansion coefficients to glass, such as Kovar alloys, are preferred. When using glass rings, it is preferable to coat metal paste to strengthen the sealing effect; The sealing ring 4 of 1 can be inserted between the two sealing rings 5 of the lower glass 2, and the gap between the three sealing rings is an air extraction channel; the upper and lower glasses are sent into a high-temperature furnace or a tempering furnace to sinter the sealing rings on the upper and lower glass Then use low-temperature glass solder to seal the upper and lower glass after assembling in a high-temperature furnace...

Embodiment 3

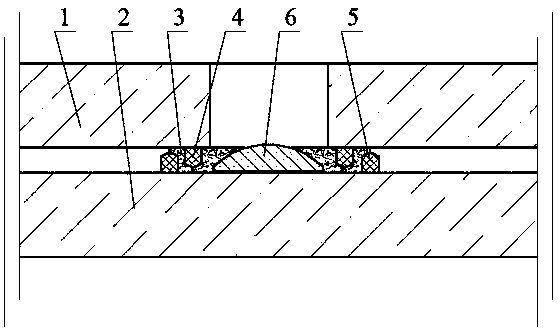

[0063] Embodiment 3: see image 3 , basically the same as Example 2, the difference is that the sealing ring 4 of the upper glass 1 is changed from a metal ring to a metal tube, and the small sealing ring 5 of the lower glass 2 is changed into a convex sheet 6. This embodiment is suitable for thicker vacuum Layers and larger suction openings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com