Dishwashing machine with a pump with a brushless permanent magnet motor

A technology for permanent magnet motors and dishwashers, which is applied to the washing machine/rinsing machine of tableware, the parts of washing machine/rinsing and washing machine of tableware, machine/engine, etc. It can solve the problem that it is impossible to determine the running direction of the impeller of the pump, etc. problem, achieve the effect of saving power and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

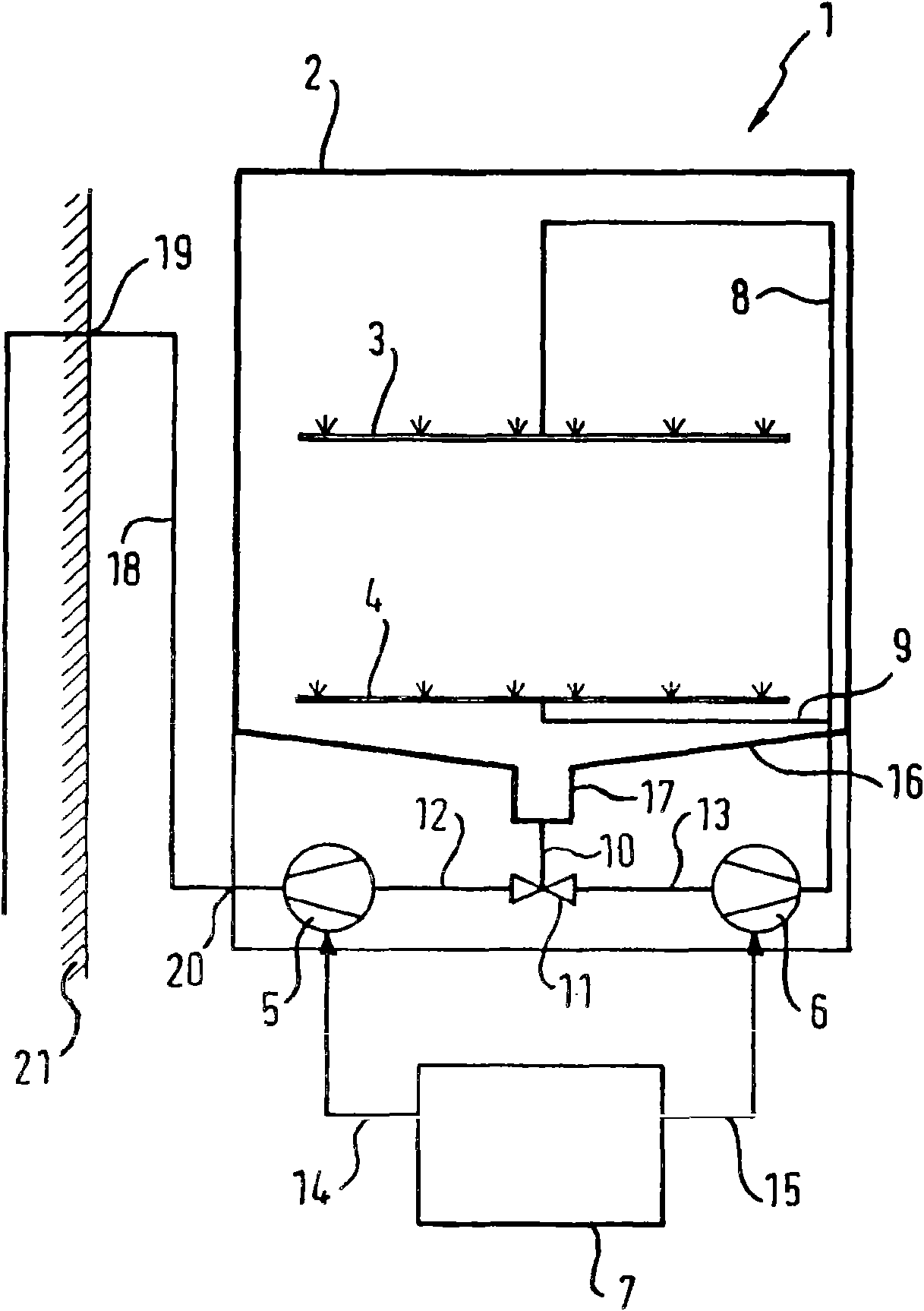

[0027] figure 1 The dishwasher 1 according to the invention is shown schematically in a sectional view. It includes a sink 2 in a known manner. The two spray arms 3 , 4 are likewise arranged in the known manner in the sink 2 and are associated in the known manner with a dish rack (not shown). Dishwashing solution incident on items to be washed (also not shown) is fed through the dishwashing tray 16 into the pump well 17 . The output of the pump well 17 is connected to the corresponding discharge pump 5 or circulation pump 6 via a line 12 or 13 respectively. The outlet of the circulation pump 6 is connected in known manner to the respective spray arm 3 or 4 via a line 8 or 9 respectively. The outlet of the drain pump 5 is connected to the outlet 20 of the dishwasher so that the dirty dishwashing fluid pumped by the drain pump 5 can be pumped via the line 18 to the household drain connection 19 provided in the wall 21, where it is necessary to overcome A defined height diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com