Disc type molecular pump

A molecular pump and disc technology, applied in the field of molecular pumps, can solve the problems of chipping damage and static vane damage, and achieve the effect of improving the pumping rate and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

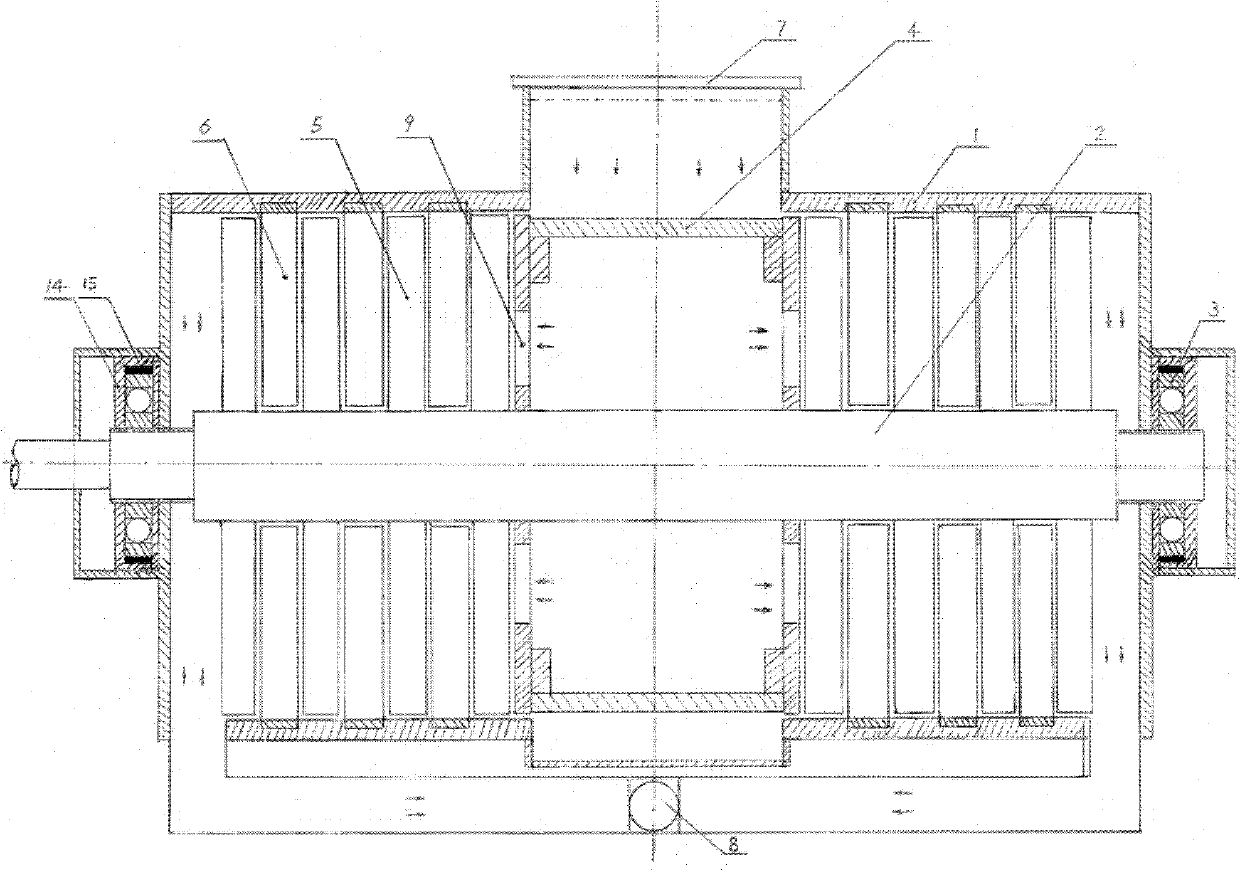

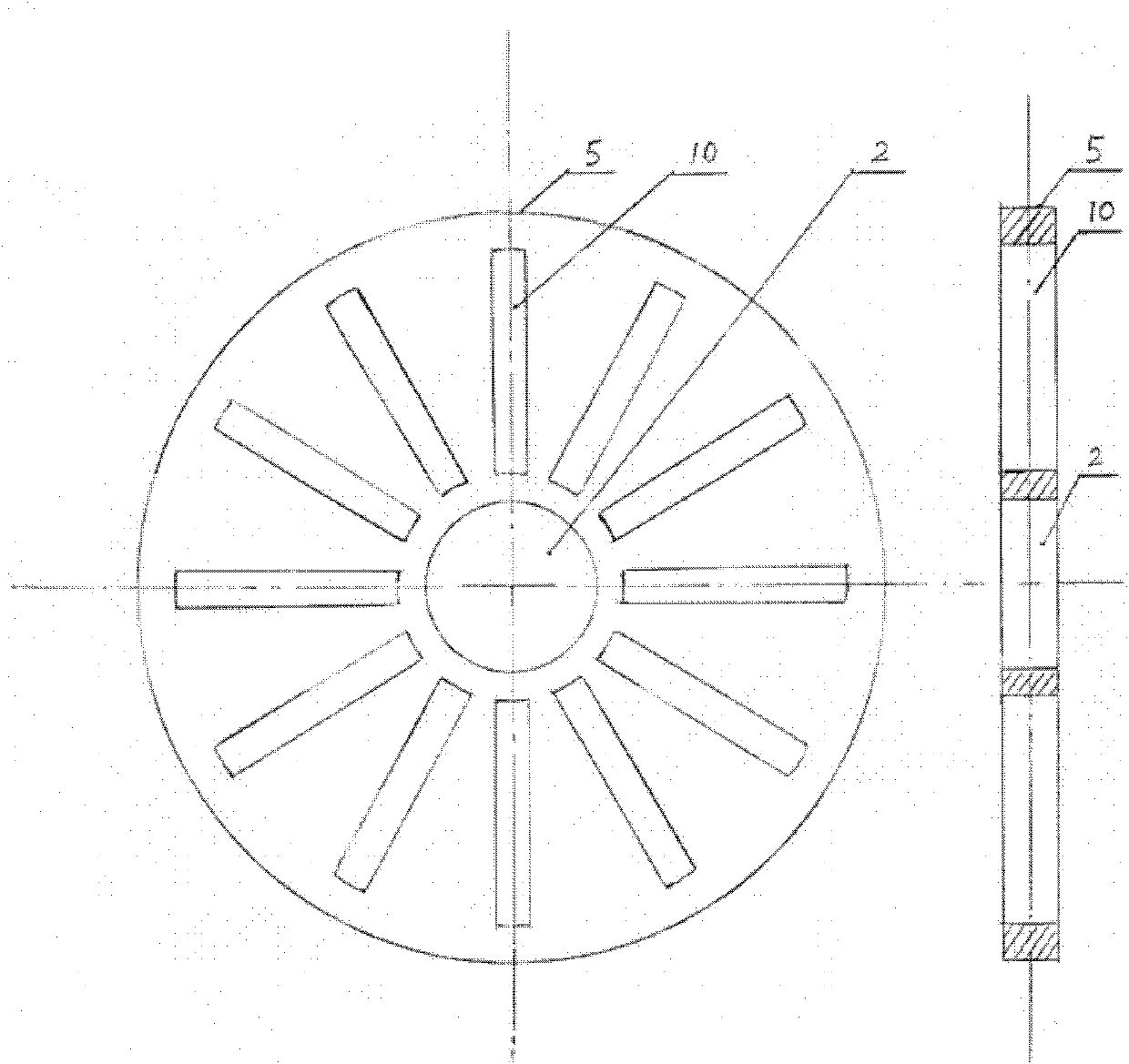

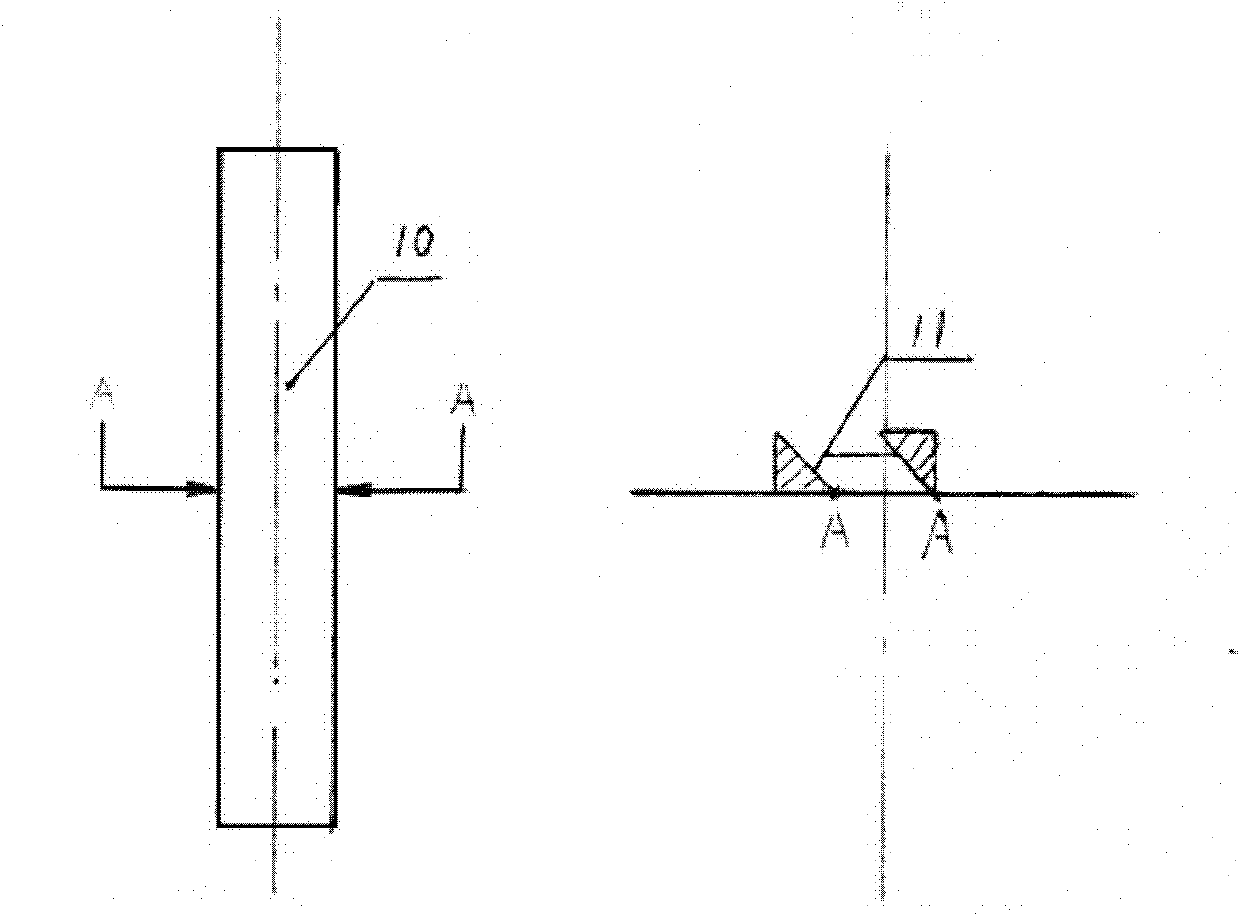

[0013] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] The pumping process of the disc molecular pump of the present invention is as follows: the gas entering the suction port first passes through the high-speed rotating squirrel-cage gas-gathering and guiding device, and then guides the gas into the left and right coaxially installed multi-stage dynamic and static circles. The air pumping unit composed of disks implements the dragging, transporting and compressing functions of gas molecules, so that the gas molecules make directional movement, and finally lead to the gas discharge port, and are taken away by the fore-stage vacuum pump.

[0015] see figure 1 , (1) is the pump body. (2) is rotating shaft. (3) is the bearing of bearing rotating shaft (2). (14) is bearing seat. (15) is shock pad, is used for reducing the vibration and the noise that the rotor of high-speed rotation brings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com