Rotation type vacuum diffusion pump

A vacuum diffusion and gyratory technology, used in diffusion pumps, non-displacement pumps, pumps, etc., can solve the problems of limited pumping speed, difficult to increase, and the ultimate vacuum cannot be further improved, so as to improve the pumping speed. , speed up the collision movement, increase the effect of the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

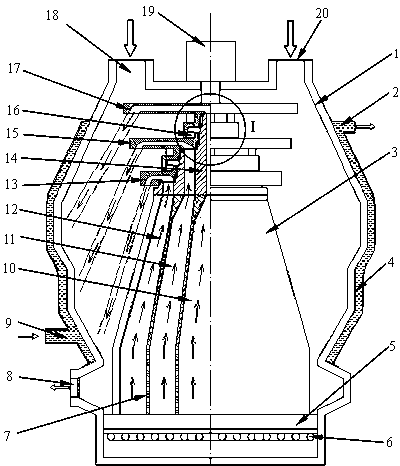

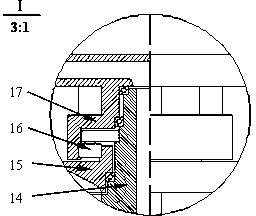

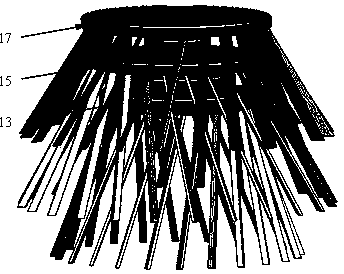

[0022] A kind of vacuum diffusion pump of the present invention such as figure 1 As shown, the basic structure includes: a pump body 1, an air inlet 18 and an air outlet 8, a filter screen 20, a cooling water tank 4, a heating device 6 and a fractionating device 5, an evaporation oil chamber 3 and a multi-stage nozzle, and the characteristic structure is: the pump The body 1 is spindle-shaped; the evaporation oil chamber 3 is conical, and there is a connecting pipe 14 connected to the multi-stage nozzles; the multi-stage nozzles are connected and driven by a planetary gear mechanism and driven by a motor 19; the nozzles are disc-shaped and spray The orifice is elliptical, and the ratio of the major axis to the minor axis of the elliptical injection port is 10-20:1.

[0023] The specific implementation is as follows:

[0024] (1) Pump body 1: spindle-shaped; there are two air inlets 18 symmetrically distributed on the top, and an air outlet 8 at the bottom; a heating device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com