Motivating fluid vacuum pump

a vacuum pump and driving agent technology, applied in the direction of pumping, positive displacement liquid engine, flexible member pump, etc., can solve the problems of small measures and the required rotational speed for the creation of displacement, the inability to sensibly integrate the pump into the system with the microcomponents, and the inability to achieve the displacement. the effect of a small displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

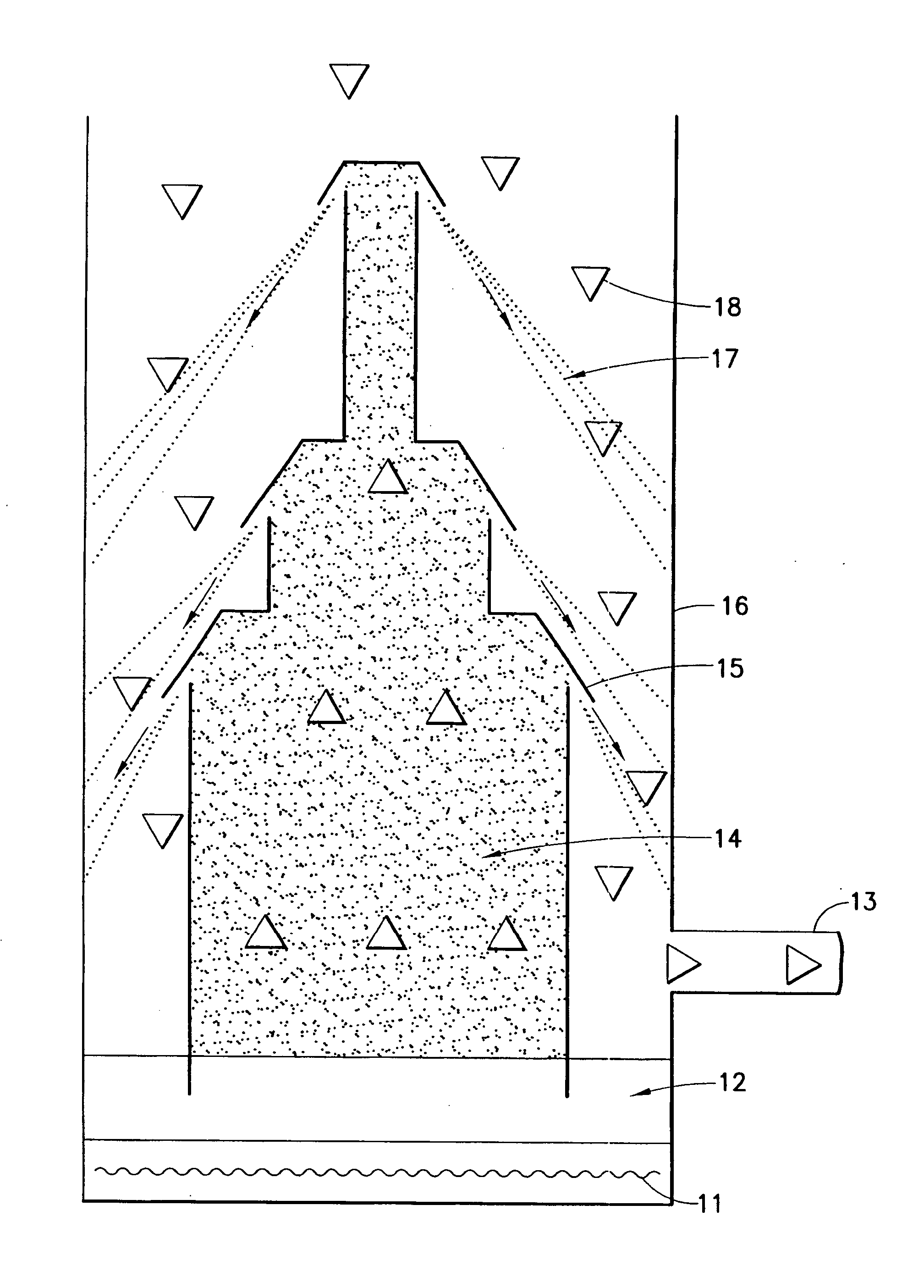

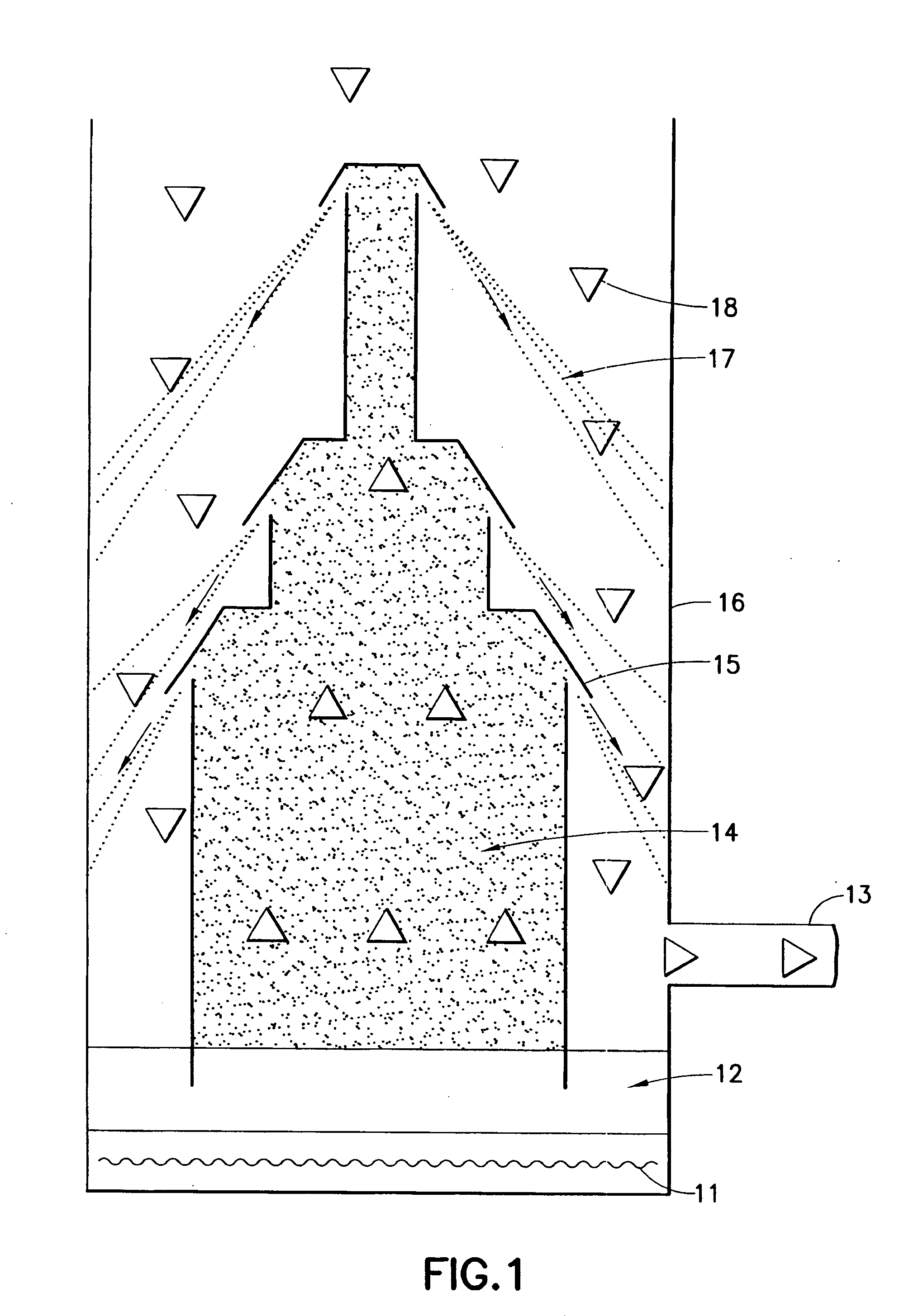

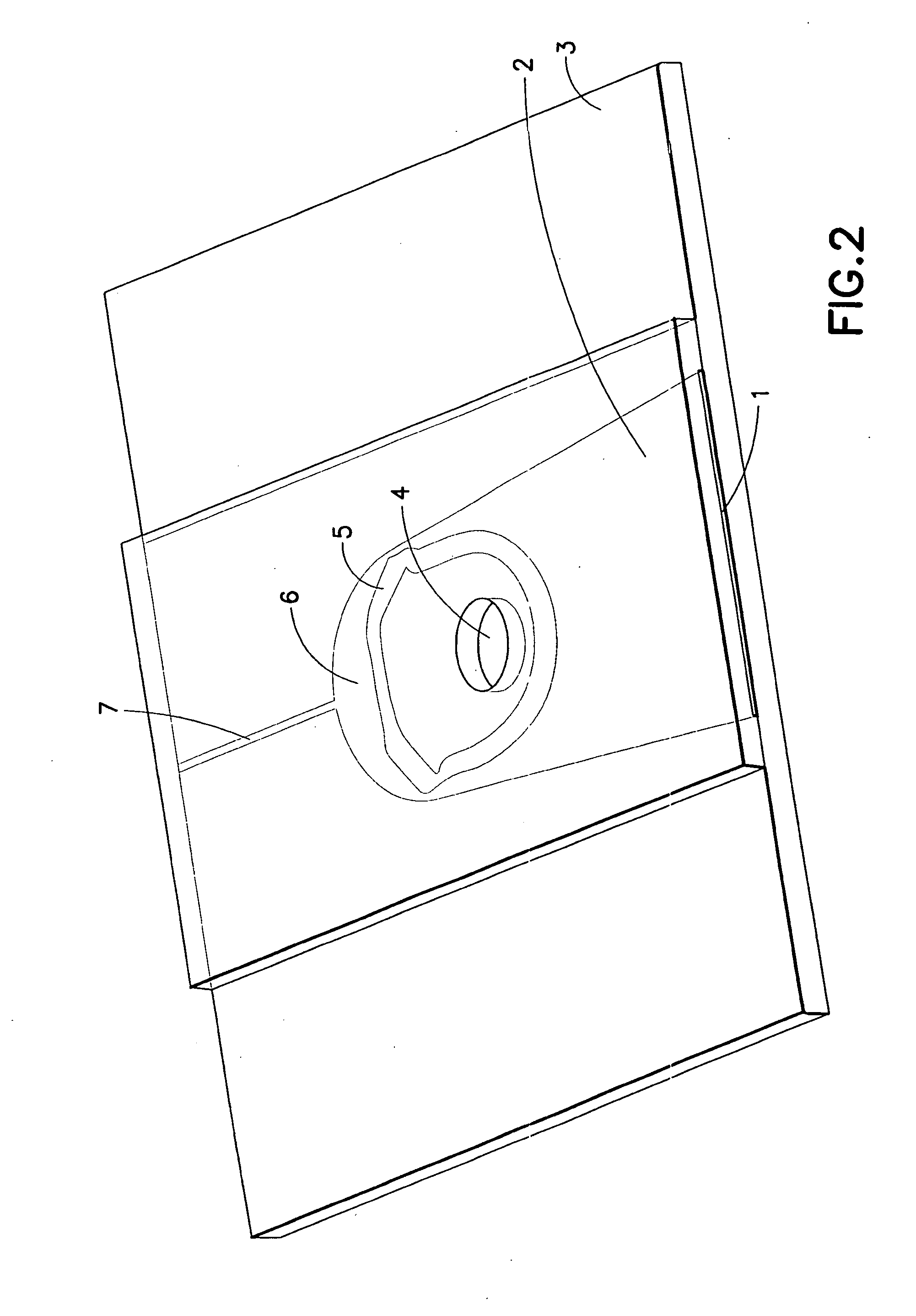

[0026] The construction of the invention consists, for example, of three substrates of which the middle substrate contains the jet structures and it is distinguished by a high heat conductibility in order to facilitate the evaporation and condensation of a liquid driving agent.

[0027] In one implementation the system or the driving agent vacuum pump is made of three substrates, the middle substrate of which because of its good heat conductibility, mechanical and chemical stability as well as its structurabilty is preferably structured by way of anisotropic etching methods, is silicon and the substrates which close its two sides are preferably because of its low thermal conductivity made of anodically bonded glass.

[0028] Moreover, in this further implementation it is advantageous if the middle substrate because of its good heat conduction is made of a galvanic metal structure, for example one made by UV-Liga technique, preferably galvanically washed on to a lower glass substrate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com