Milk-frothing device with dynamic mixing unit, and beverage maker containing the same

A dynamic mixing and foaming device technology, applied in mixers, beverage preparation devices, kitchen utensils, etc., can solve the problems of mutual influence, limited variability, small flexibility, etc., and achieve the effect of improving foamability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

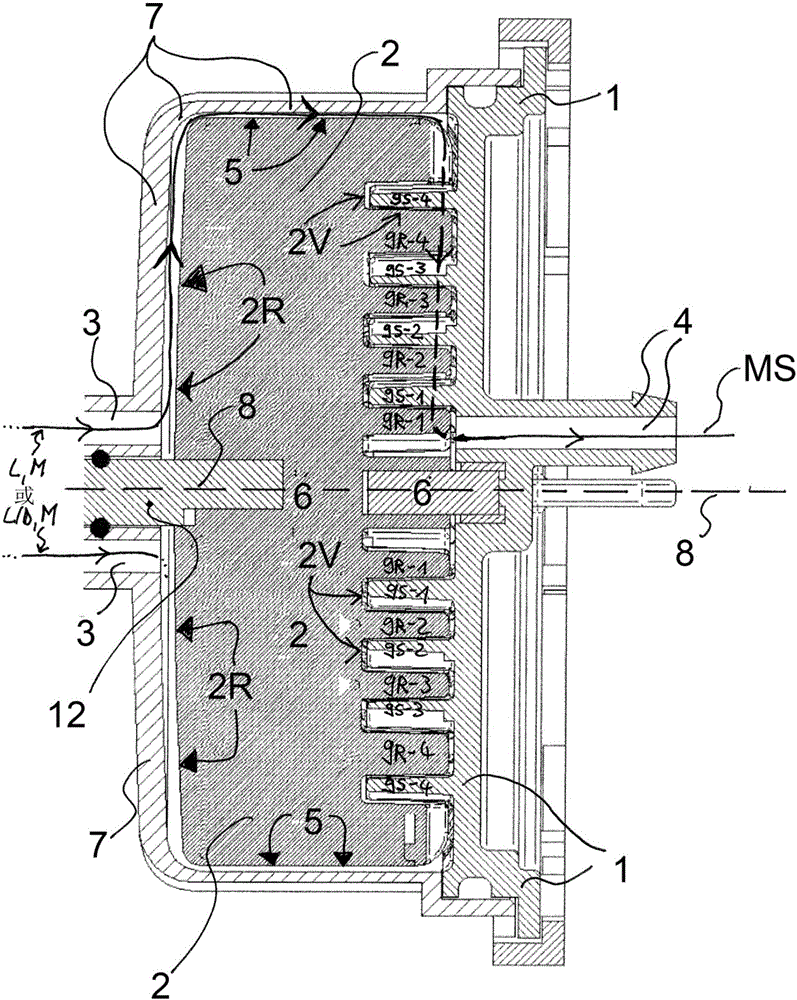

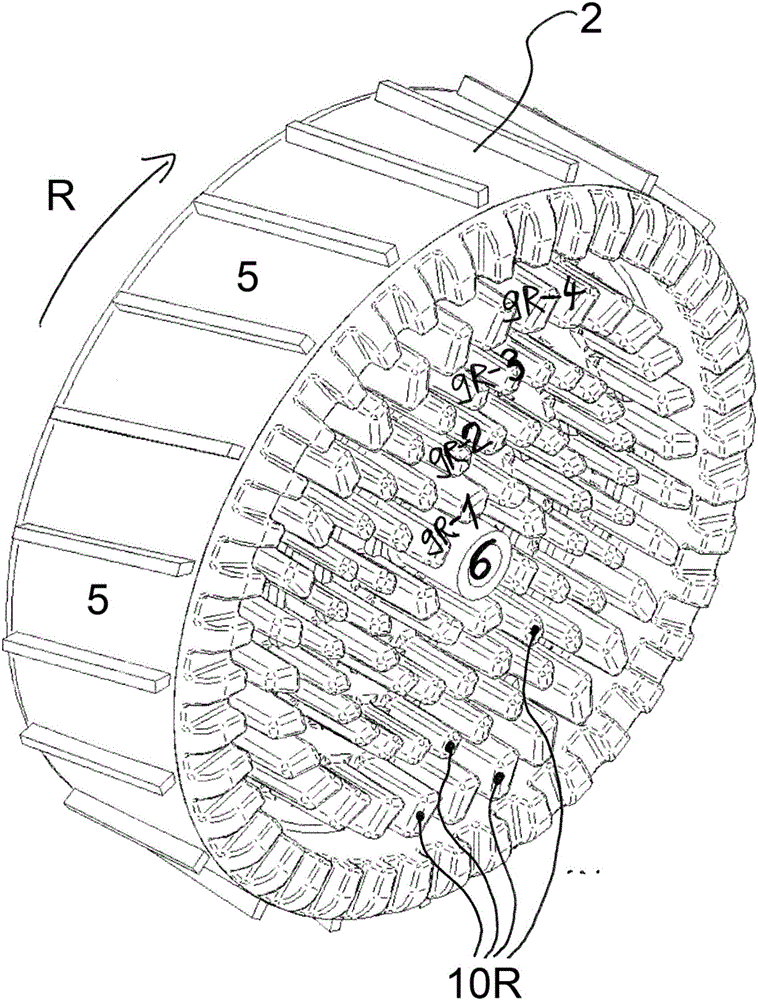

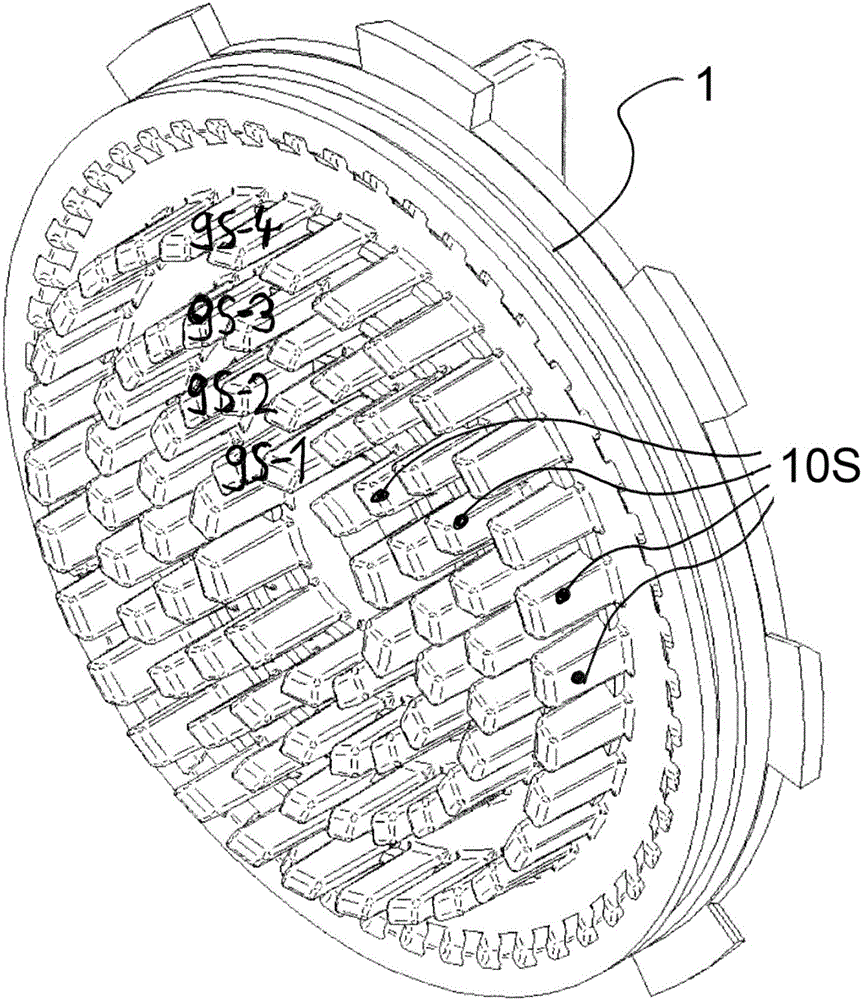

[0057] figure 1 A first milk frothing device according to the invention is shown in cross section in the plane through which the axis of rotation 8 of the stator-rotor assembly extends. Figure 2a shows a three-dimensional view, and image 3 a shows a top view (parallel to the axis of rotation 8 ) of the rotor 2 of the milk frothing device. Figure 2b shows a three-dimensional view, and image 3 b shows a top view (parallel to the axis of rotation 8 ) of the stator 1 of the milk frothing device.

[0058] Such as figure 1 As shown, the conveying channel 3 , which here comprises two partial channels, leads parallel to the axis of rotation 8 , but at a distance therefrom, as far as directly onto the rear surface 2R of the rotor 2 . This conveying channel 3 serves to convey milk M and air L or a milk M and air-steam mixture to the rear surface 2R of the rotor 2 . The rear side 2R (as far as the gap) is positively surrounded by the housing part 7 of the milk frothing device. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com