A kind of foamed TPU composite phase change energy storage material and preparation method thereof

A technology of phase change energy storage materials and energy storage materials, which is applied in the field of energy recovery and utilization, can solve problems such as low toughness, low thermal conductivity, and low energy storage rate, and achieve the effect of expanding types and functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The invention discloses a foamed TPU composite phase change energy storage material, which comprises 50% phase change energy storage material powder and 50% TPU. The phase change energy storage material powder includes 80% PEG, 12% EG, and 8% AC foaming agent.

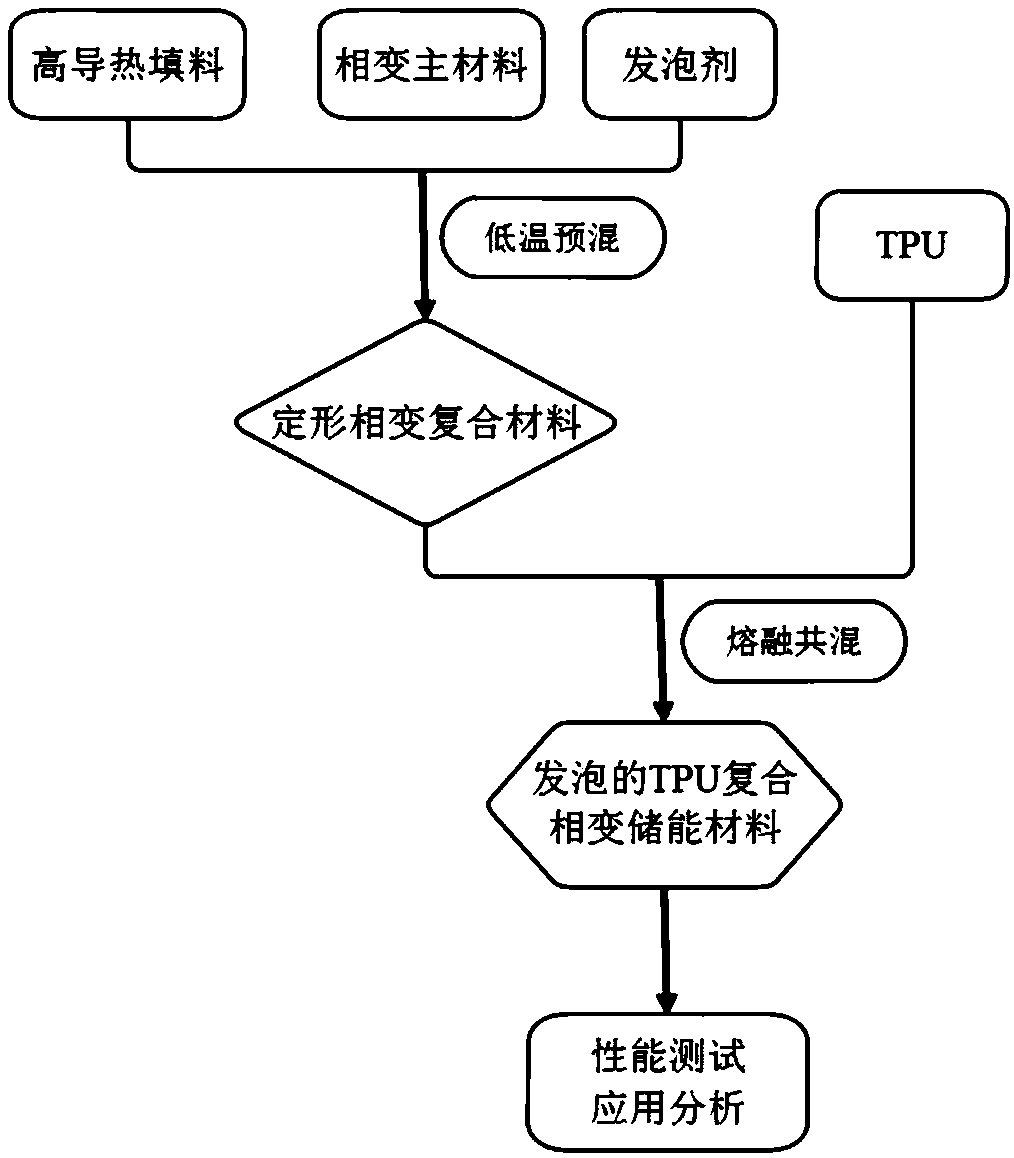

[0036] A kind of preparation method of the TPU composite phase-change energy storage material of the present invention, such as figure 1 As shown, first prepare the powder material of the organic polymer composite phase change energy storage material with high thermal conductivity and high phase change enthalpy that can be expanded, and mix 80% of PEG, 12% of EG, and 8% of AC foaming agent Pour it into an internal mixer at 80°C. After the PEG is completely melted, keep the temperature constant and then banbury and mix for 5 minutes; finally cool and grind to obtain the powder of the composite phase change energy storage material. Then 50% of the composite phase change energy storage material powder and 50% of th...

Embodiment 2

[0038] The invention discloses a foamed TPU composite phase change energy storage material, which comprises 60% phase change energy storage material powder and 40% TPU. The powder material of the phase change energy storage material includes 90% of paraffin, 9% of ACG, and 1% of AC foaming agent.

[0039] A method for preparing a foamed TPU composite phase-change energy storage material in the present invention, firstly prepare the powder material of a foamable organic polymer composite phase-change energy storage material with high thermal conductivity and high phase-change enthalpy, and mix 90% Pour 1% paraffin wax, 9% ACG, and 1% AC foaming agent into a 70°C internal mixer. After the paraffin wax is completely melted, keep a constant temperature and then banbury and mix for 15 minutes; finally cool and grind to obtain a composite phase change energy storage powder material. Then 60% of the composite phase change energy storage material powder and 40% of fully dry TPU are p...

Embodiment 3

[0041] The invention discloses a foamed TPU composite phase change energy storage material, which comprises 70% phase change energy storage material powder and 30% TPU. The phase change energy storage material powder includes 50% hexadecane, 40% SiO 2 , 10% AC foaming agent.

[0042] A preparation method of a foamed TPU composite phase change energy storage material of the present invention, first prepares the powder material of a foamable high thermal conductivity high phase change enthalpy organic polymer composite phase change energy storage material, and mixes 50% Hexadecane, 40% SiO 2 1. Pour 10% AC foaming agent into a 50°C internal mixer. After the hexadecane is completely melted, keep the constant temperature and then banbury and mix for 20 minutes; finally cool and grind to obtain the powder of the composite phase change energy storage material. Then 70% of the composite phase change energy storage material powder and 30% of the fully dry TPU are premixed in a high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com