Preparation method of lithium battery diaphragm

A lithium battery diaphragm, an organic technology, applied in the field of lithium battery diaphragm preparation, can solve the problems of difficulty in preparing large-area membranes, high diaphragm cost, and poor uniformity, and achieve good promotion prospects, good stability, and heat resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

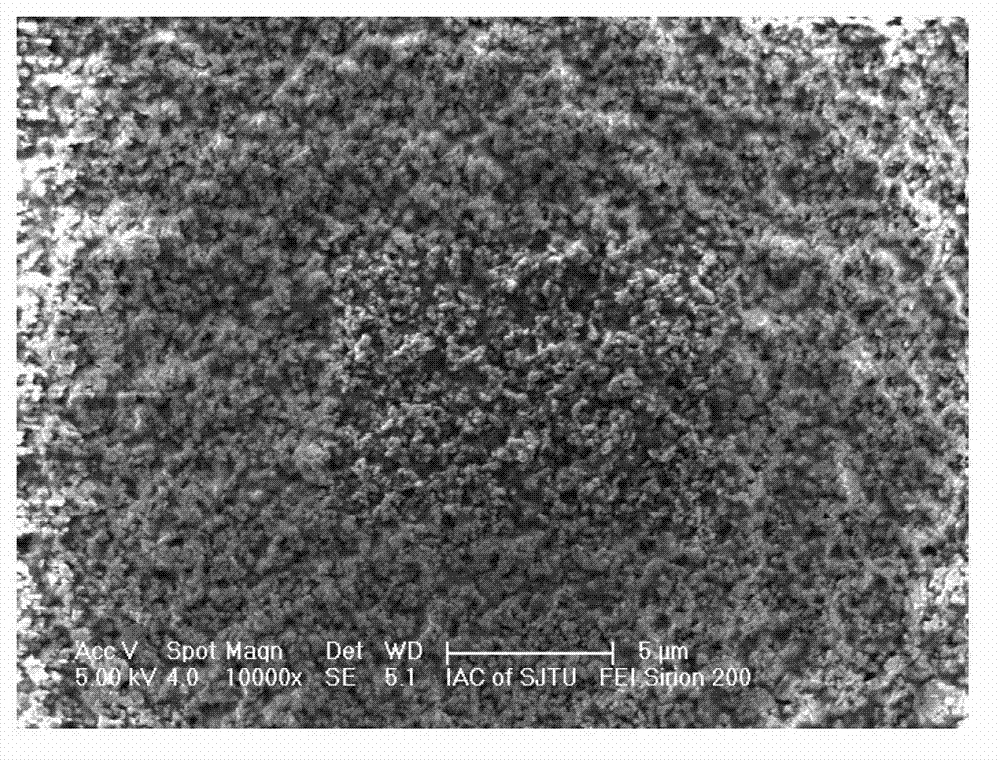

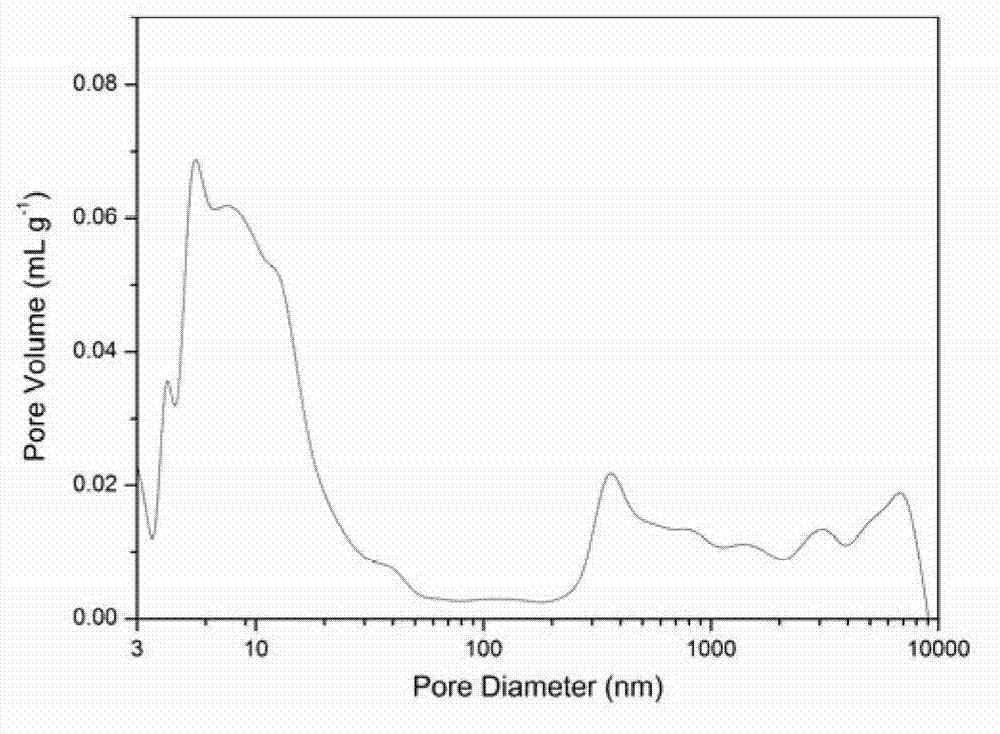

[0026] This embodiment relates to a preparation method of a lithium battery diaphragm, comprising the following steps:

[0027] (a) dissolving polyvinylidene fluoride in dimethylformamide to obtain polyvinylidene fluoride (4wt%) solution;

[0028] (b) Nano-Al 2 o 3 The powder is added in the product polyvinylidene fluoride (4wt%) solution obtained from the above step (a), and the nanometer Al 2 o 3 The weight ratio of powder to polyvinylidene fluoride is 2:1, mix evenly, heat at 50°C, heat for 1 hour, and ball mill to obtain nano-Al 2 o 3 A mixture of powder dispersed in polyvinylidene fluoride solution;

[0029] (c) the above-mentioned step (b) gained product nano-Al 2 o 3 The mixture of powder dispersed in polyvinylidene fluoride solution is poured on a stainless steel substrate, and the drying temperature is 80°C. After drying for 3 hours, the final product Al 2 o 3 / Polyvinylidene fluoride composite diaphragm.

[0030] Implementation effect: see Table 1 and Tabl...

Embodiment 2

[0032] This embodiment relates to a preparation method of a lithium battery diaphragm, comprising the following steps:

[0033] (a) dissolving polyvinylidene fluoride in dimethylformamide to obtain polyvinylidene fluoride (5wt%) solution;

[0034] (b) Nano-Al 2 o 3 Powder is added in the product polyvinylidene fluoride (5wt%) solution of above-mentioned step (a) gained, nanometer Al 2 o 3 The weight ratio of powder to polyvinylidene fluoride is 1:1, mix uniformly, heat at 60°C, heat for 1.5 hours, and ball mill to obtain nano-Al 2 o 3 A mixture of powder dispersed in polyvinylidene fluoride solution;

[0035] (c) the above-mentioned step (b) gained product nano-Al 2 o 3 The mixture of powder dispersed in polyvinylidene fluoride solution is poured on the silicon wafer substrate, and the drying temperature is 85 ° C. After drying for 3.5 hours, the final product Al 2 o 3 / Polyvinylidene fluoride composite diaphragm.

[0036] Implementation effect: see Table 1 and Tabl...

Embodiment 3

[0038] This embodiment relates to a preparation method of a lithium battery diaphragm, comprising the following steps:

[0039] (a) dissolving polyvinylidene fluoride in dimethylformamide to obtain polyvinylidene fluoride (6.7wt%) solution;

[0040] (b) Nano-Al 2 o 3 The powder is added in the product polyvinylidene fluoride (6.7wt%) solution obtained from the above step (a), and the nanometer Al 2 o 3 The weight ratio of powder to polyvinylidene fluoride is 1:2, mix evenly, heating temperature is 70°C, after heating for 2 hours, ball mill to get nano Al 2 o 3 A mixture of powder dispersed in polyvinylidene fluoride solution;

[0041] (c) the above-mentioned step (b) gained product nano-Al 2 o 3 The mixture of powder dispersed in polyvinylidene fluoride solution is poured on a glass substrate, and the drying temperature is 90 ° C. After drying for 4 hours, the final product Al 2 o 3 / Polyvinylidene fluoride composite diaphragm.

[0042] Implementation effect: see Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com