Plant fiber diatom ooze and preparation process thereof

A plant fiber and plant fiber powder technology, applied in the field of composite materials, can solve the problem of lack of removal of free formaldehyde to purify the air and negative ions to freshen the air, etc., and achieve excellent practicability and decorative comprehensive performance, excellent elasticity and sound absorption and heat insulation performance. Excellent crack performance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

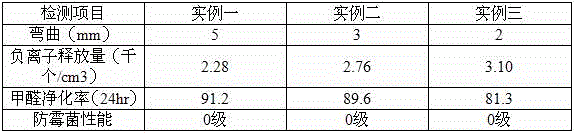

Examples

preparation example Construction

[0029] A preparation process of plant fiber diatom mud comprises the following process steps.

[0030] Step 1: Accurately weigh the materials in the formula according to the weight ratio.

[0031] Step 2: Automatically add materials with a total weight of more than 5 kg into the double-helix stirring tank with the elevator in turn, and directly add materials below 5 kg into the stirring tank to avoid loss of the elevator, and then close the upper hatch.

[0032] Step 3: Start the stirring tank at a speed of 100-500 rpm, and stir for 50-60 minutes.

[0033] Step 4: Open the lower hatch, the stirred diatom ooze is filtered through a 60-120 mesh vibrating screen, and then enters the hopper of the automatic packaging machine to start packaging.

Embodiment 1

[0035] 30% diatomite, 10% plant fiber powder, 10% kaolin, 2% bentonite; 5% anion powder; 5% titanium dioxide; 5% amedadone; 10% calcite powder; 15% calcium ash; Latex powder 7%; powder defoamer 0.2%; powder wetting agent 0.2%; powder antifungal agent 0.2%; hydroxypropyl methylcellulose 0.4%.

[0036] The raw materials in the formula of Example 1 above were mixed for 1 hour at a speed of 200 rpm through a twin-screw mixer, then passed through a 110-mesh sieve, and packaged to obtain plant fiber diatom mud.

[0037] The construction process is as follows: add the prepared plant fiber diatom mud into clean water according to the proportion, stir well, let it stand for half an hour, then make up water, adjust to a suitable consistency and stir for 5 minutes, and then filter it with a fine sieve. Carry out batch scraping or bomb coating construction.

Embodiment 2

[0039] 20% diatomite; 30% plant fiber powder, 8% kaolin; 4% bentonite; 5% negative ion powder; 3% titanium dioxide; Latex powder 5%; powder defoamer 0.2%; powder wetting agent 0.2%; powder antifungal agent 0.2%; hydroxypropyl methylcellulose 1.4%.

[0040] The raw materials in the formula of Example 1 above were mixed for 1 hour at a speed of 300 rpm through a twin-screw mixer, then passed through a 90-mesh sieve, and packaged to obtain plant fiber diatom mud.

[0041] The construction process is as follows: add the prepared plant fiber diatom mud into clean water in proportion and stir well, let it stand for half an hour, then make up water, adjust to a suitable consistency and stir for 5 minutes before batch scraping or bomb coating construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com