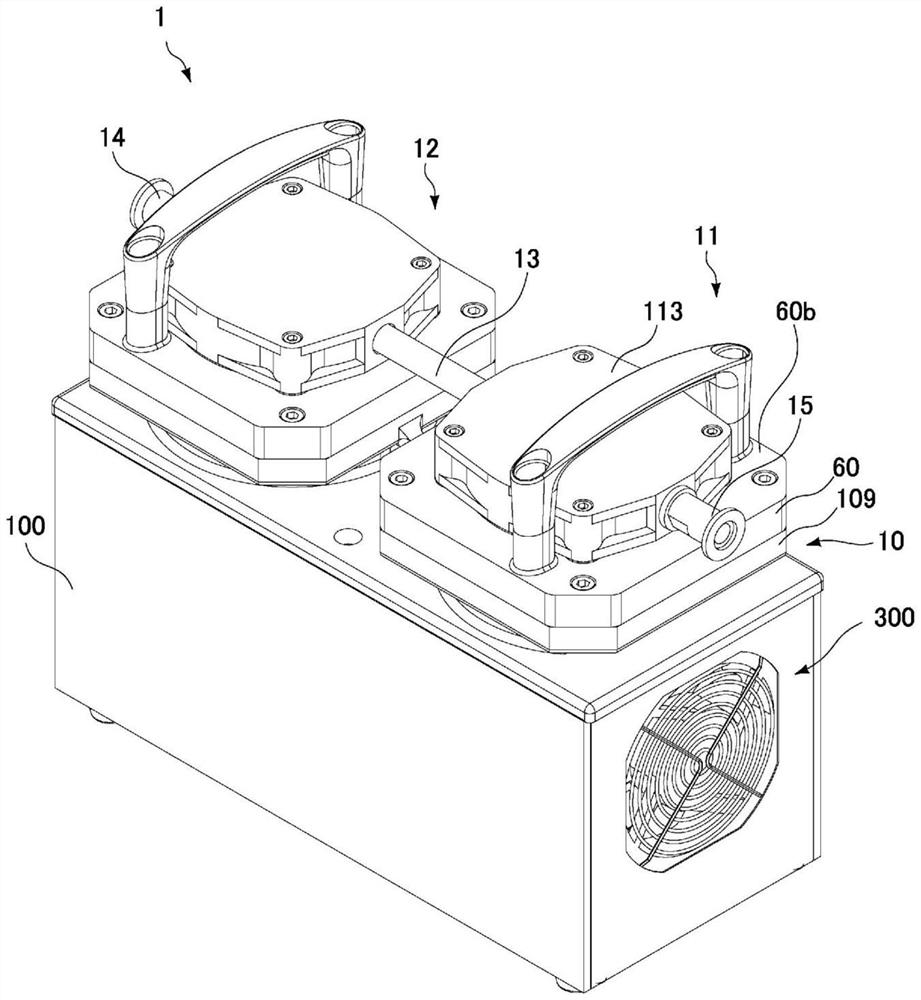

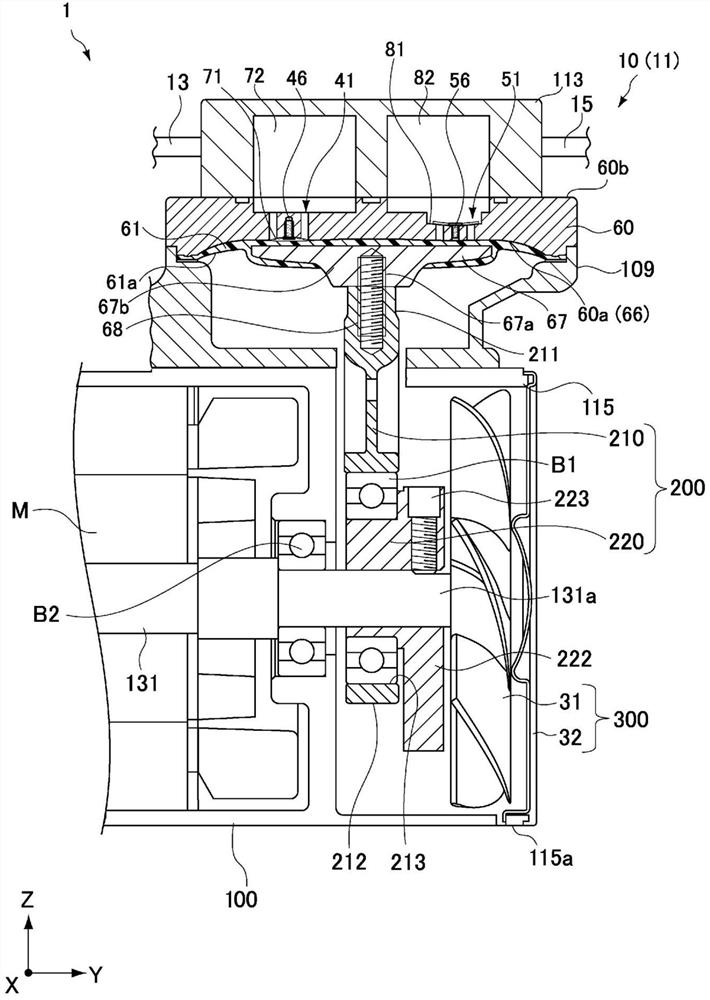

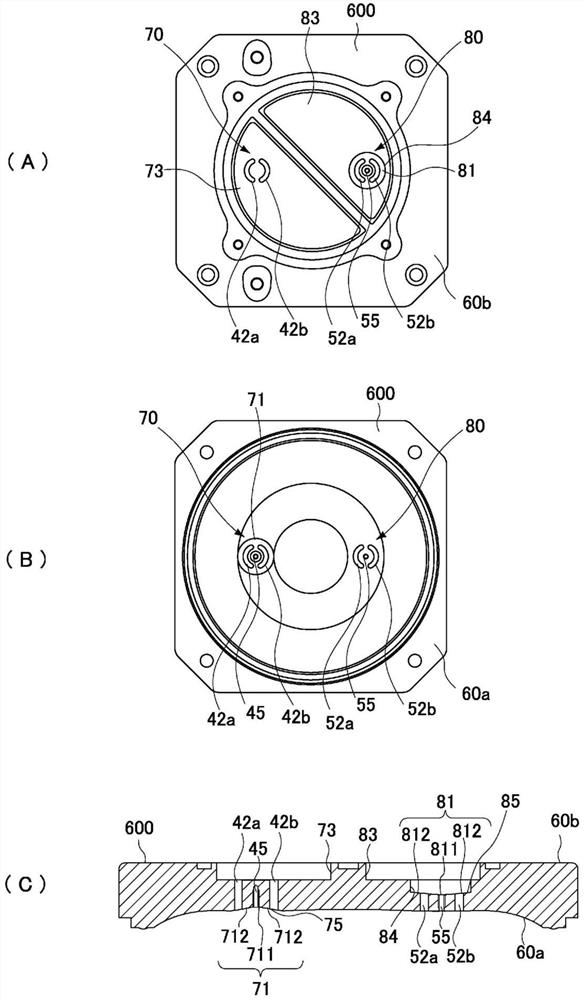

Valve units, pump heads and pump units

A valve device and valve seat technology, which is applied to valve devices, cocks including cut-off devices, pumps, etc., can solve the problems of dead zone reduction and difficulty in increasing the ultimate vacuum degree, and achieve the effect of increasing the ultimate vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0189] Table 1 shows the measurement results of the ultimate pressure of the pump device equipped with the pump head 60 according to the present embodiment together with the measurement results obtained by using a conventional pump device.

[0190] In Table 1 below, a diaphragm-type dry vacuum pump manufactured by ULVAC Co., Ltd., model number DA-241S, was prepared as a pump device having a one-stage compression structure of a conventional product.

[0191] A pump unit in which the pump head of a diaphragm type dry vacuum pump model DA-241S manufactured by ULVAC Corporation was replaced with the pump head 60 of this embodiment was prepared as a one-stage compression structure equipped with the pump head 60 of this embodiment. pump unit.

[0192] A diaphragm-type dry vacuum pump model DA-121D manufactured by ULVAC Co., Ltd. was prepared as a pump device having a two-stage compression structure of an existing product.

[0193] A pump unit in which the pump head of a diaphragm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com