Centralized ejection vacuum pump

A vacuum pump and collection technology, which is applied to jet pumps, pumps, non-displacement pumps, etc., can solve the problems of large pumping volume and difficulty, and achieve the effect of reducing pumping energy consumption, good effect and avoiding energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

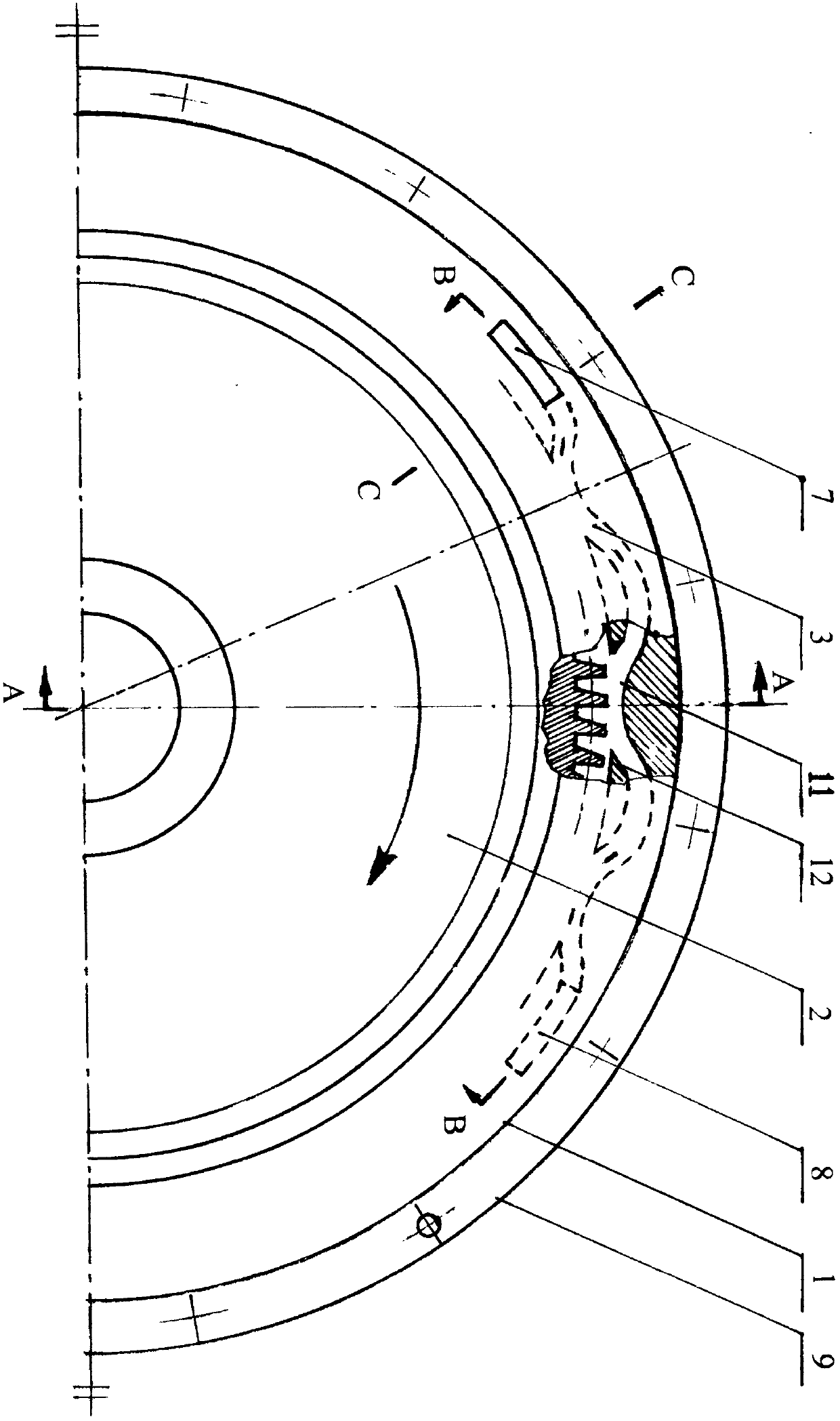

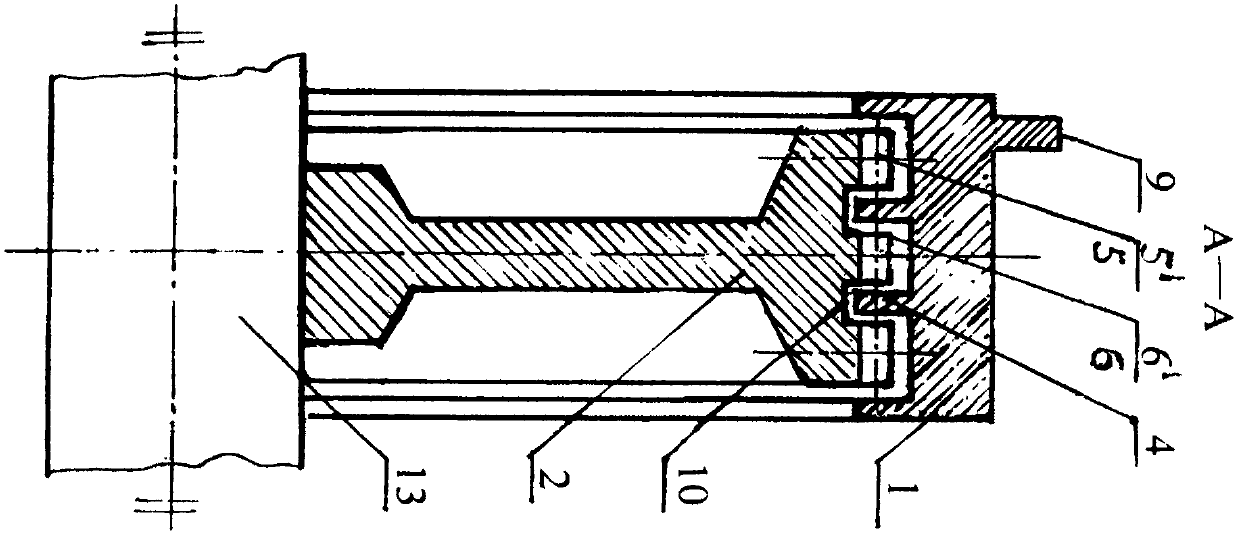

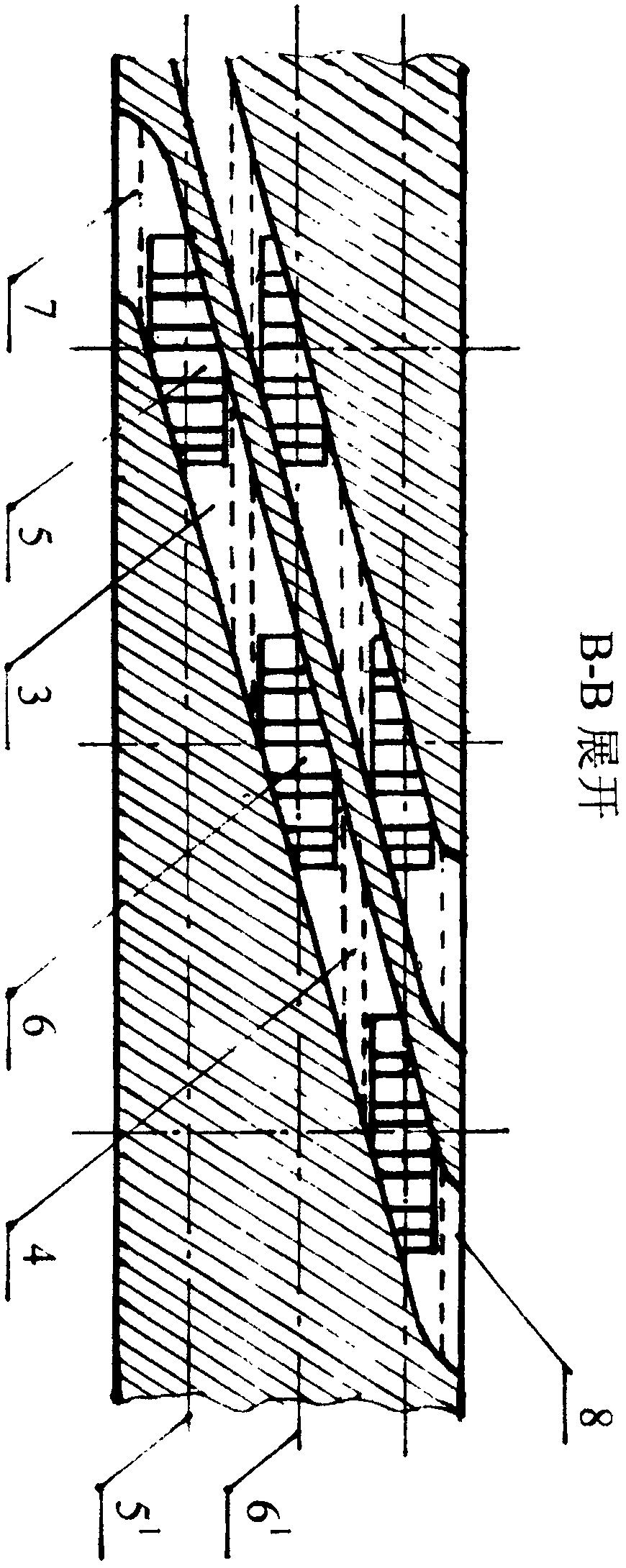

[0010] The ejector vacuum pump of the present invention is mainly composed of a pump body 1, a shaft 13, a gear 2, a bearing, a pump cover and the like. The inner cavity of the pump body 1 is provided with a spacer ring 4, which divides the inner cavity of the pump body into different injection chambers; at the same time, the pump body 1 is also provided with a pumping and discharging channel 3 with radial undulations and axial helical propulsion. The front end of the pumping channel 3 is an air suction port 7, the rear end is an exhaust port 8, and the middle part communicates with each ejection cavity step by step at a small diameter. The gas that enters the exhaust channel 3 through the suction port is first combined with the first-stage ejection cavity 5 1 Connected and in contact with the first-stage tooth row 5 of the gear 2, the pumped gas is pumped and pressurized and transported to the Secondary injection chamber 6 1 Contact and interact with the secondary tooth row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com