Molecular-distillation purification method of celery seed oil and purification device thereof

A celery seed oil and molecular distillation technology, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of high technical requirements for operators, low degree of automation, and large operation time lag, so as to reduce costs and improve production efficiency , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

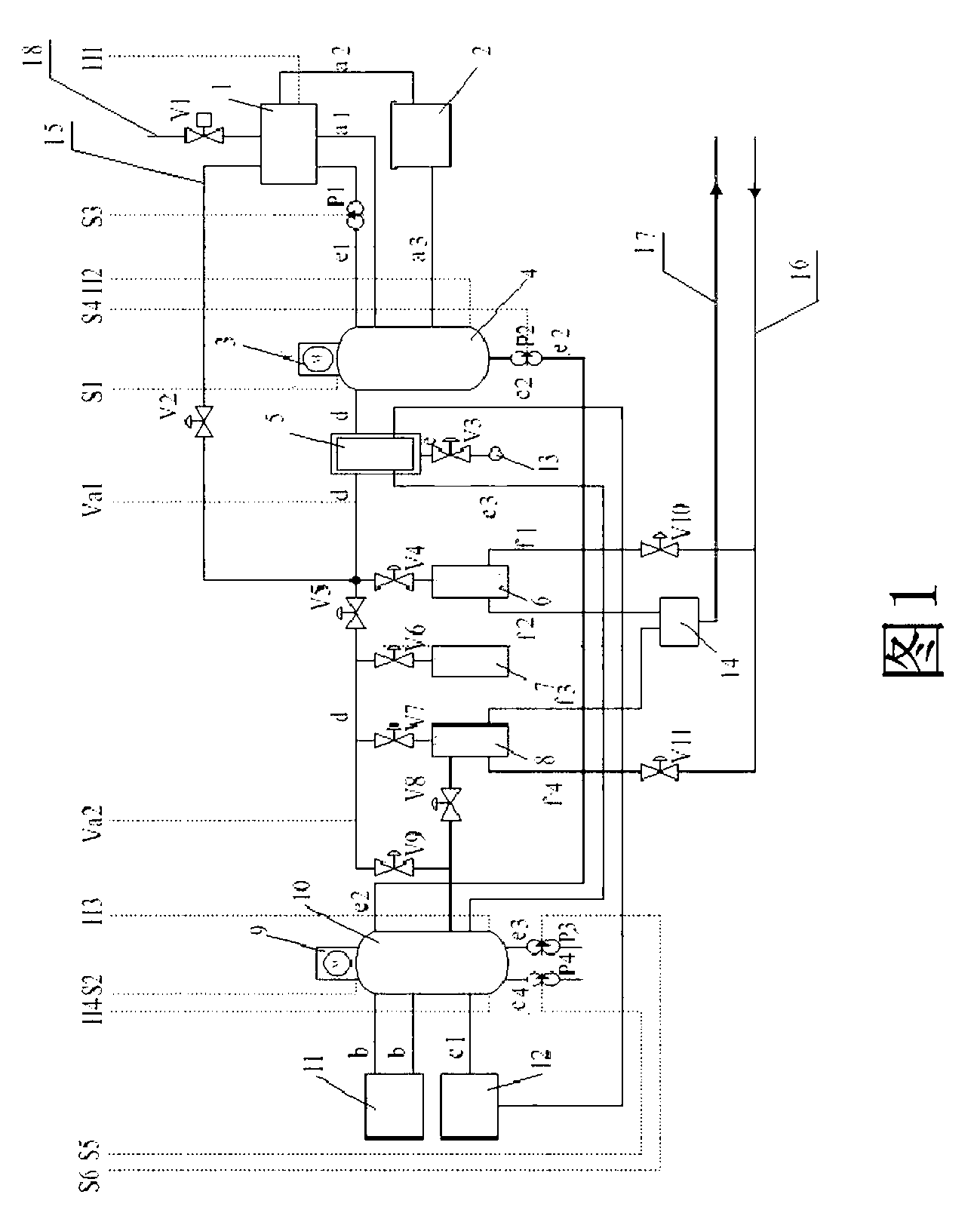

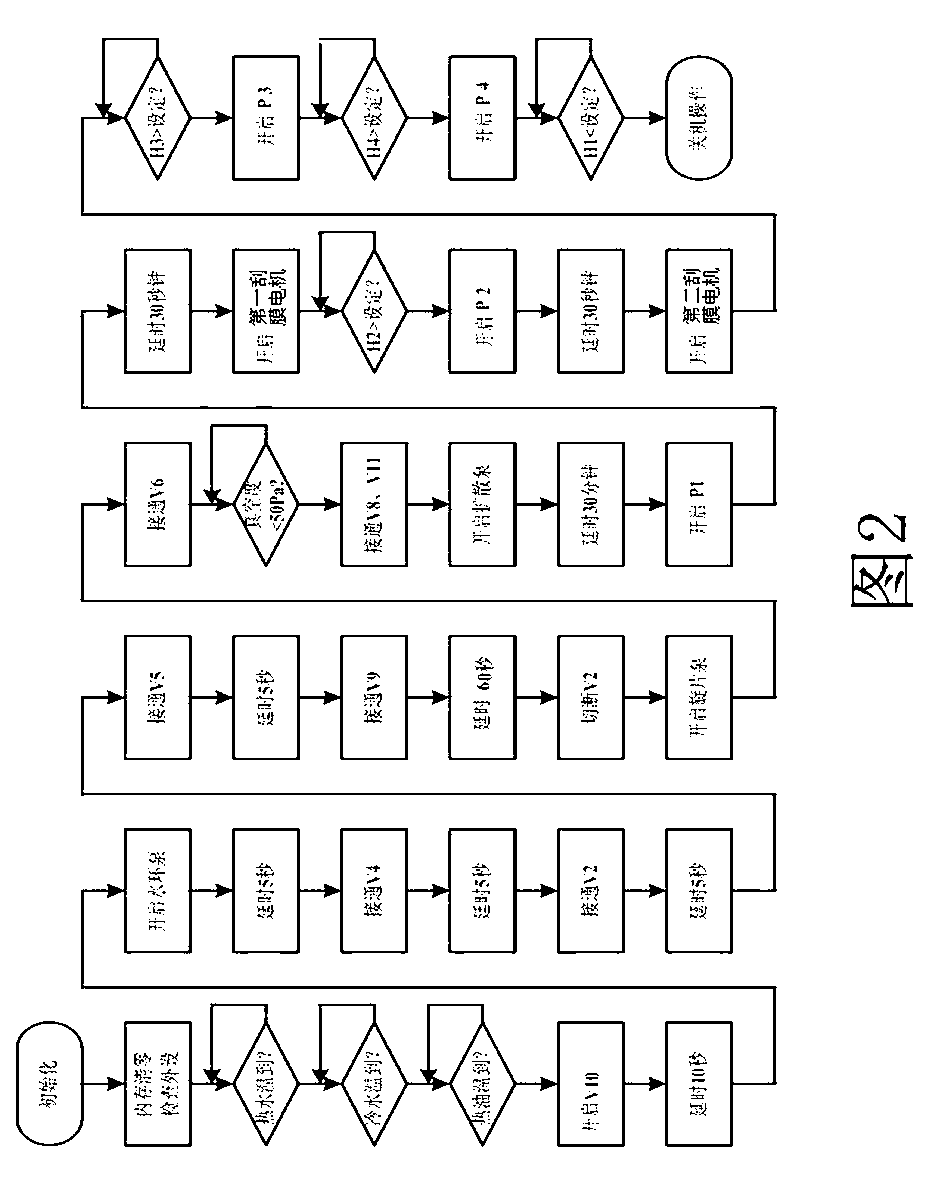

[0058] see figure 1 , figure 2 Shown:

[0059]The molecular distillation purification device of celery seed oil of the present invention is made up of thermal oil machine 11, chiller 12, material tank 1, constant temperature tank 2, I-stage evaporator 4, II-stage evaporator 10, cold well 5, water The ring pump 6, the rotary vane pump 7, the diffusion pump 8 and the controller are composed. The thermal oil machine 11 is connected with the second-stage evaporator 10 through the thermal oil pipeline b. There are two thermal oil pipelines b. One end of the chiller 12 The first cooling water pipe c1 communicates with the second-stage evaporator 10, the other end of the chiller 12 communicates with the cold well 5 through the second cooling water pipe c2, and the cold well 5 communicates with the second-stage evaporator through the third cooling water pipe c3 The first-stage evaporator 4 and the second-stage evaporator 10 are connected by the vacuum chamber pipe d and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com