Device and method for preparing combined film material warehouse

A technology for combining thin films and material libraries, which is applied in the field of devices for preparing combined thin film material libraries, can solve the problems of low operability, less dynamic parameterized design, and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

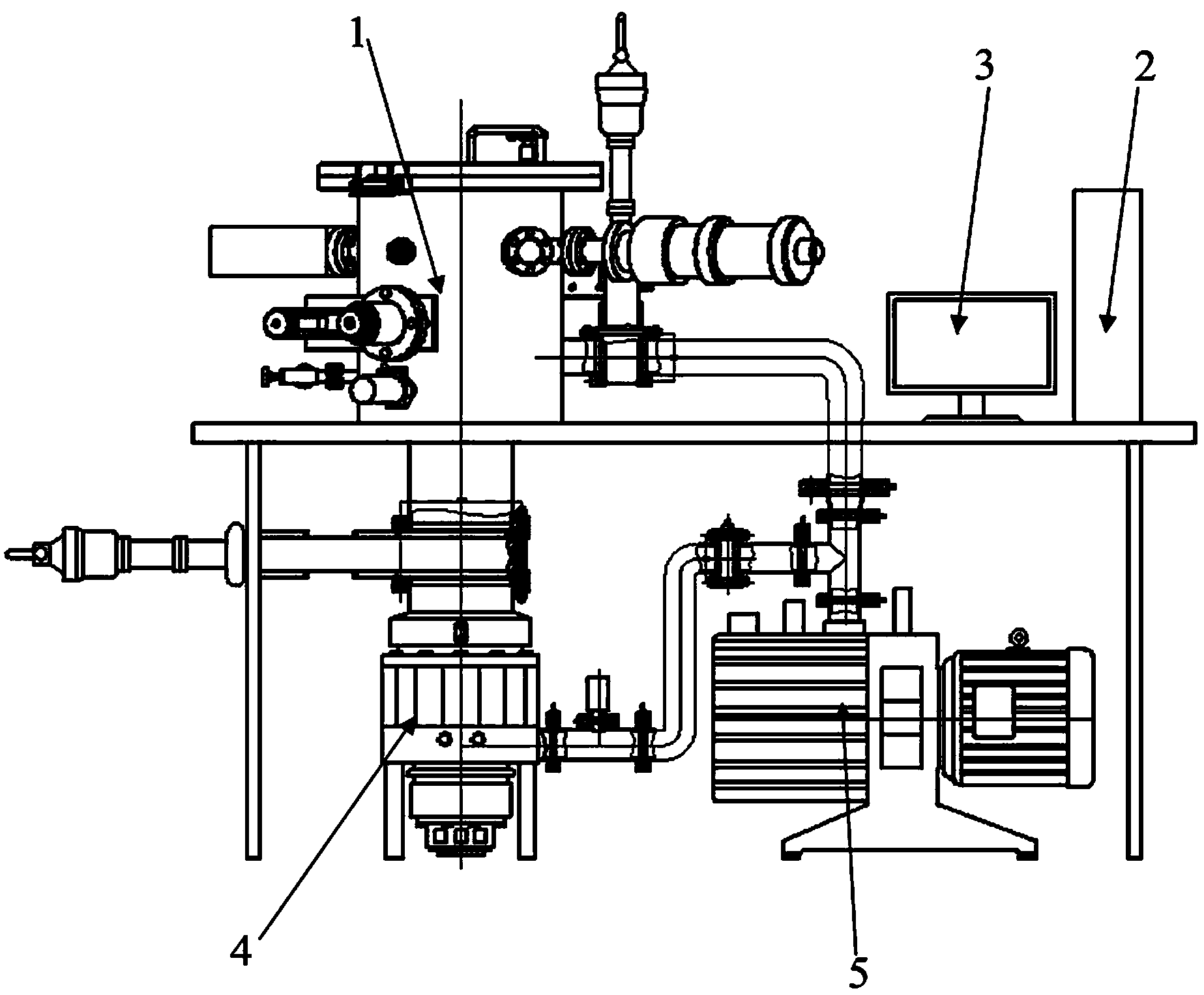

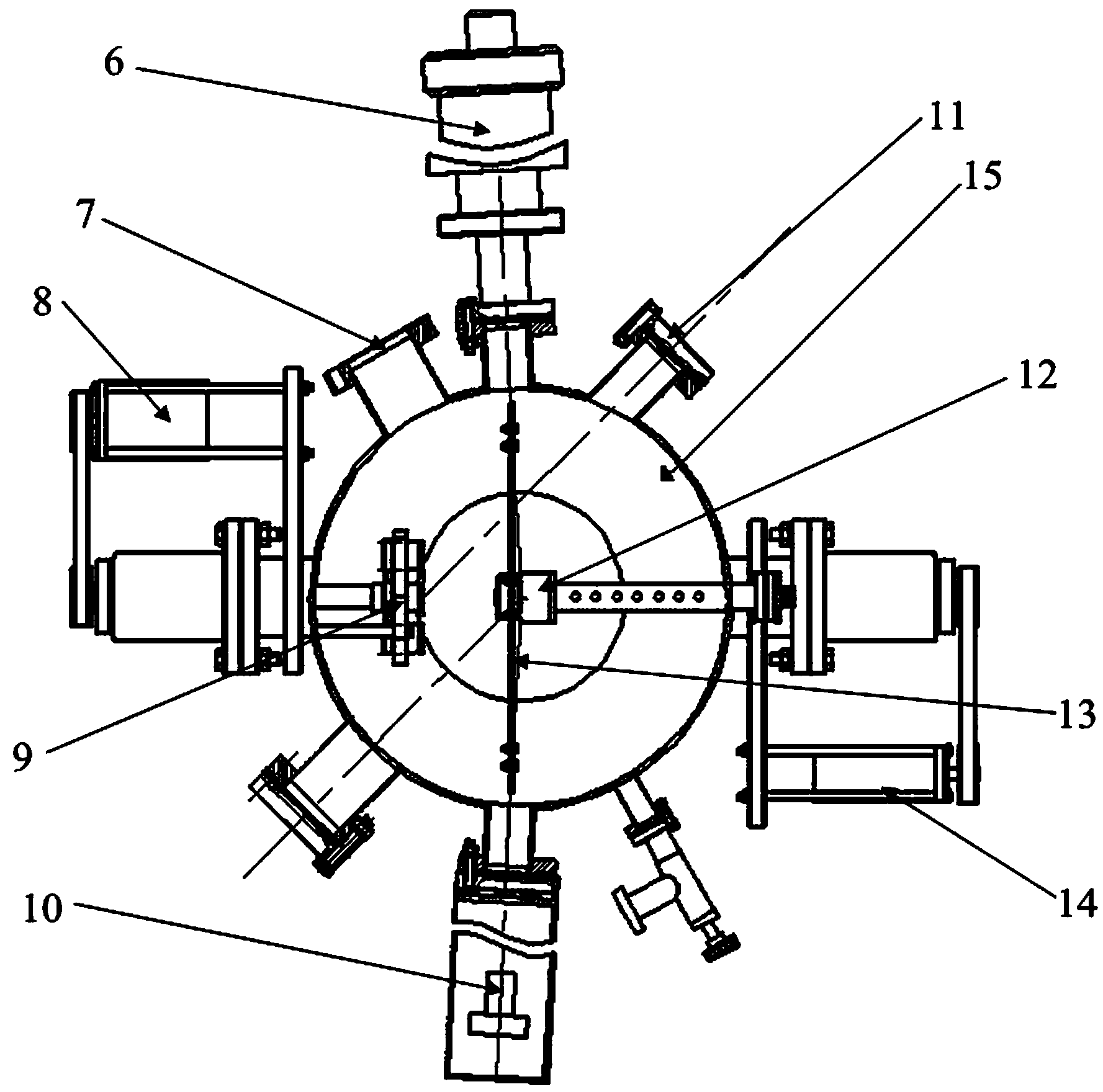

[0095] The computer adopted in the embodiment of the present invention controls the 40CB servo motor and the 2303HC58D8X stepping motor respectively through the MPC08 motion control card, controls the RHEED electron gun and the laser through the KSA400RHEED control system, and the composite molecular pump model in the embodiment is PNFB150 / 600, and the rotary vane pump The model is 2XZ-8.

[0096] step 1:

[0097] Determine the deposited Ba x Sr 16-x TiO 3 Binary phase diagram, design the structure, shape and component distribution of the combined thin film material library to be prepared, and give the composition distribution equation of each component of the thin film material, that is, the relationship between the composition content of each component of the film and the deposition position, Make sure the selected target is BaTiO 3 and SrTiO 3 two kinds;

[0098] Step 2:

[0099] Mask shape design for the combined thin film material library to be prepared;

[0100] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com