Magnetic drive vane pump

a vane pump and magnetic drive technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve problems such as unintended fluid lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

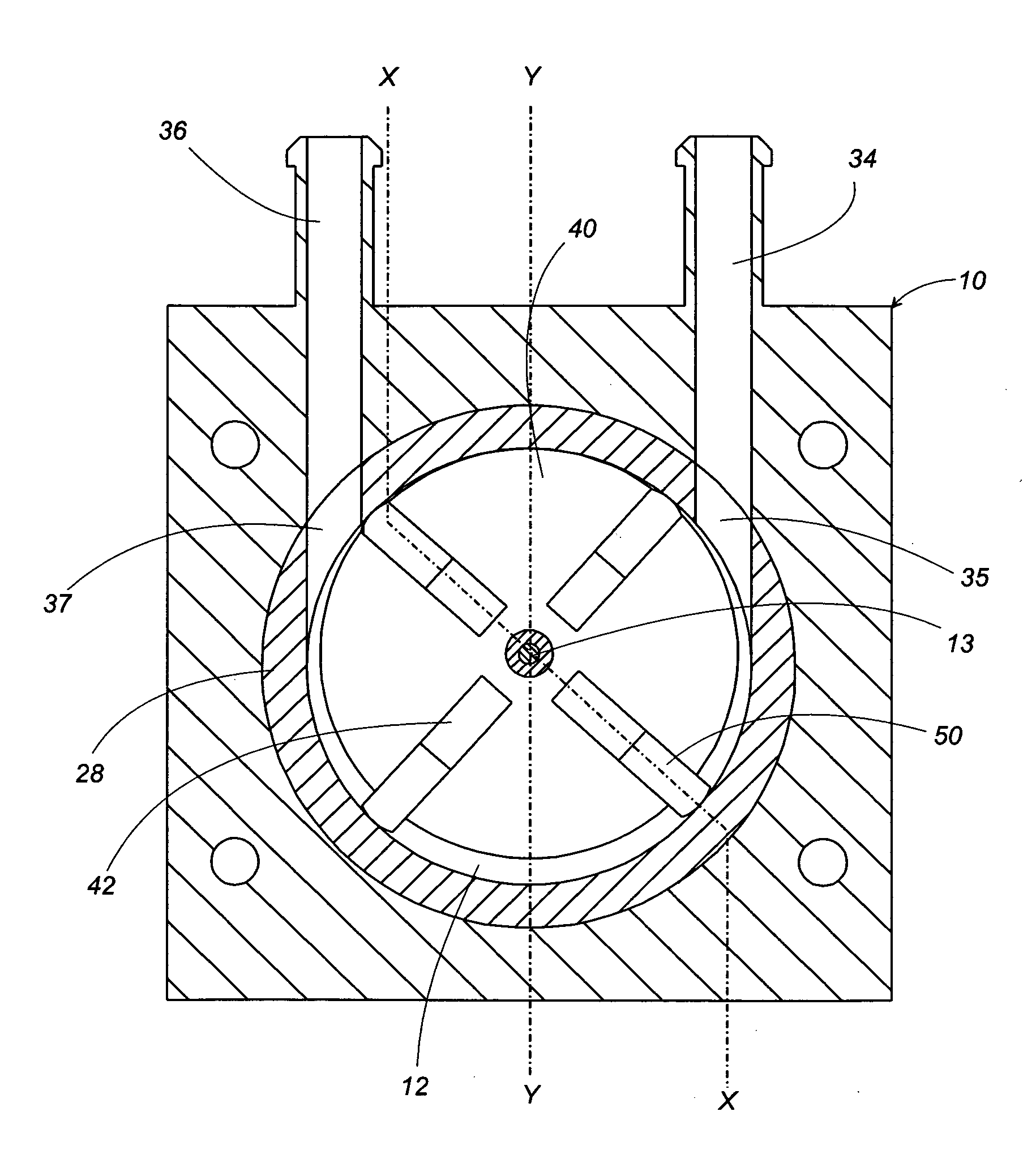

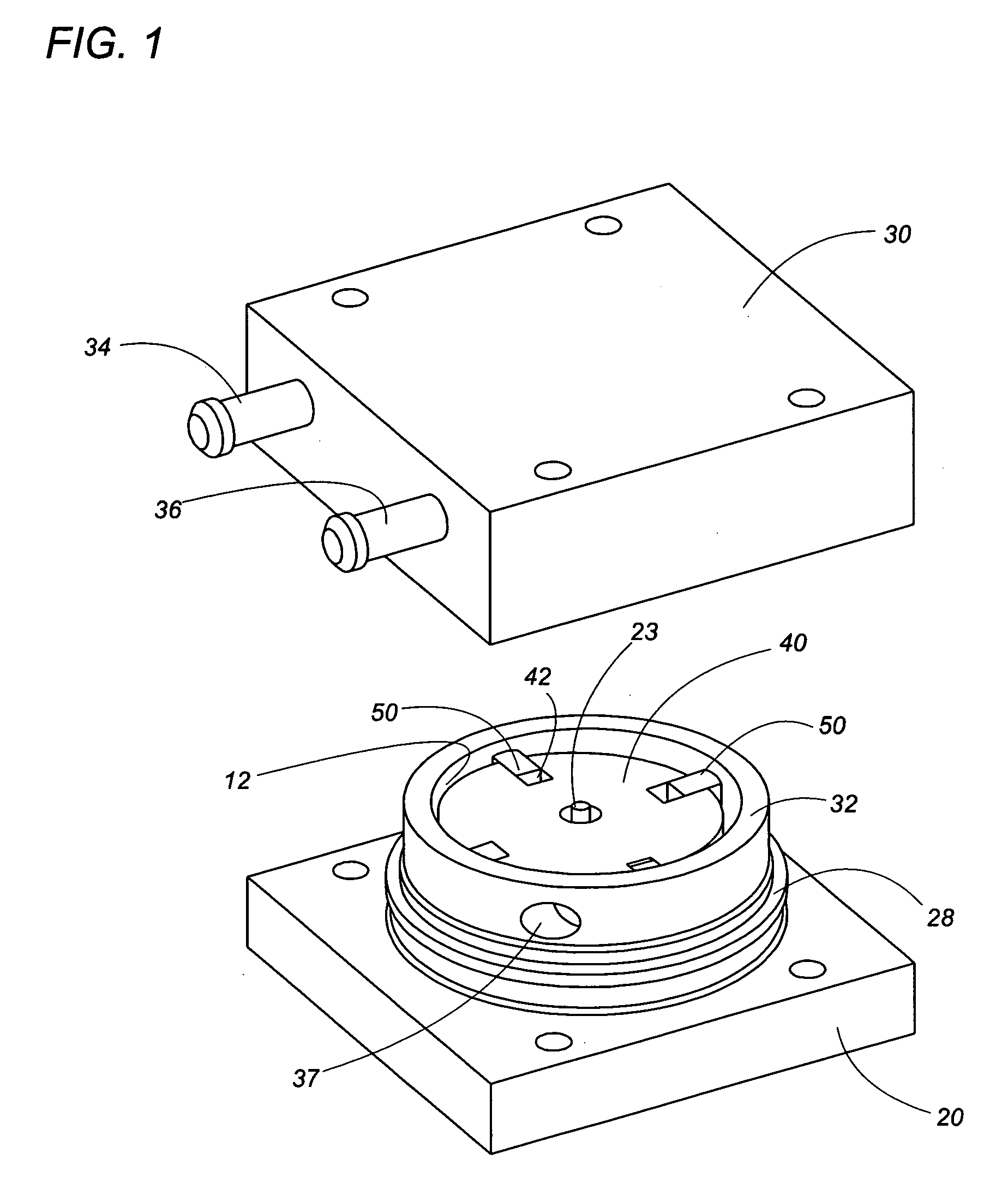

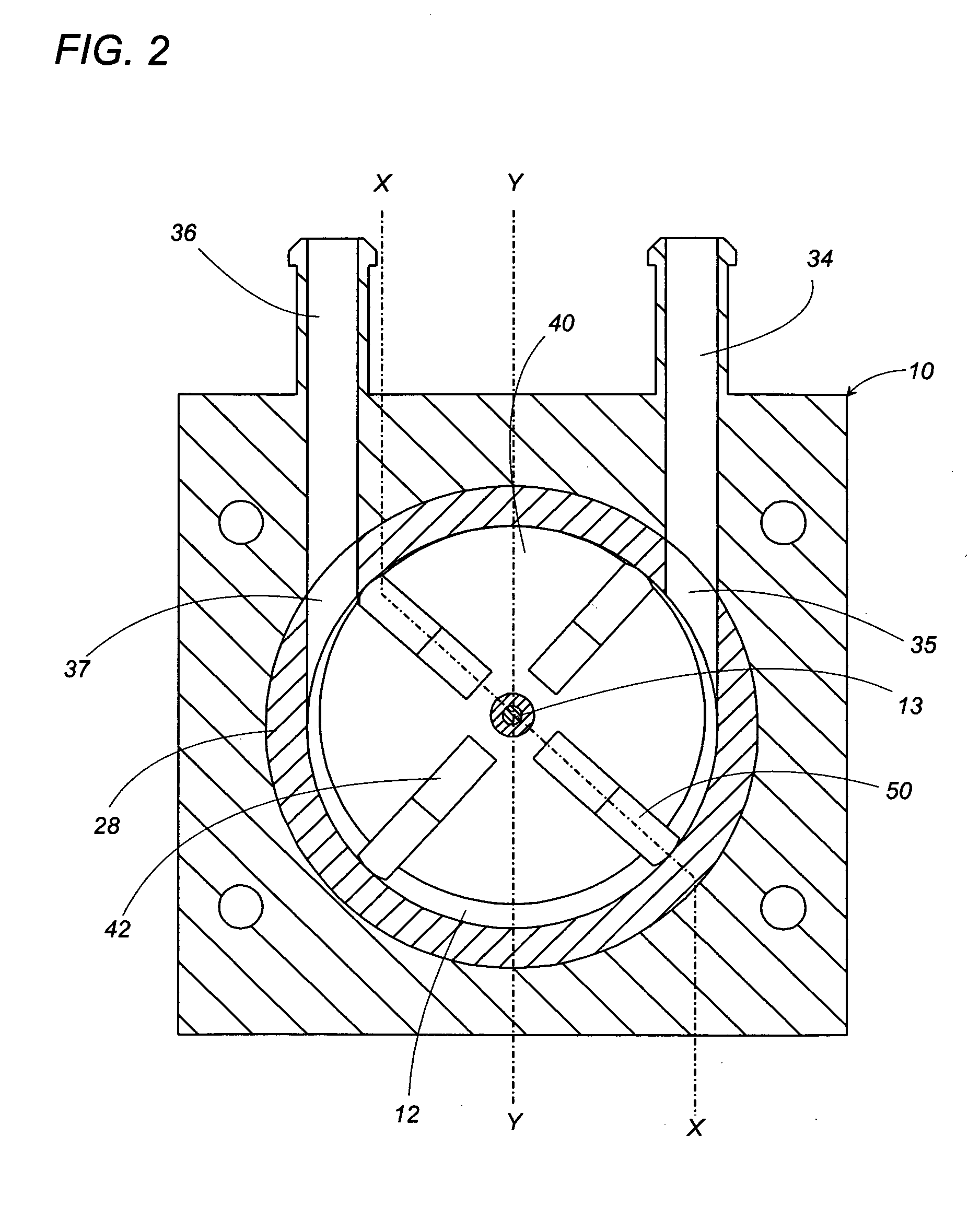

[0018]Referring now to FIGS. 1 to 4, there is shown a magnetic drive vane pump in accordance with a first embodiment of the present invention. The pump includes a casing 10 formed in its interior with a cylindrical pump cavity 12 which accommodates therein a rotor 40 having an eccentric axis offset from an axis of the pump cavity 12. The casing 10 is composed of a lower half 20 and an upper half 30 which are secured to each other with a sealing ring 14 held therebetween. The lower and upper halves 20 and 30 are respectively formed with a lower recess 21 and an upper recess 31 which are cooperative to define the pump cavity 12. As seen in FIGS. 3 and 4, the lower half 20 is formed to have a center stud 22 anchoring a shaft 23, and an annular projection 26 between the center stud 22 and a peripheral wall 28. The shaft 23 projects from the center stud 22 into a center concavity 29 of the lower half 20 to define the eccentric axis, and is surrounded by a bearing sleeve 24. A ring 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com