Unit forevacuum and leak detector integration system for molecular pump

A pre-evacuation, integrated system technology, applied in the direction of pump, pump test, pump device, etc., can solve the problems of energy consumption, waste of man-hours, long response time for evacuation and leak detection, etc., and achieve the effect of prolonging service life and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

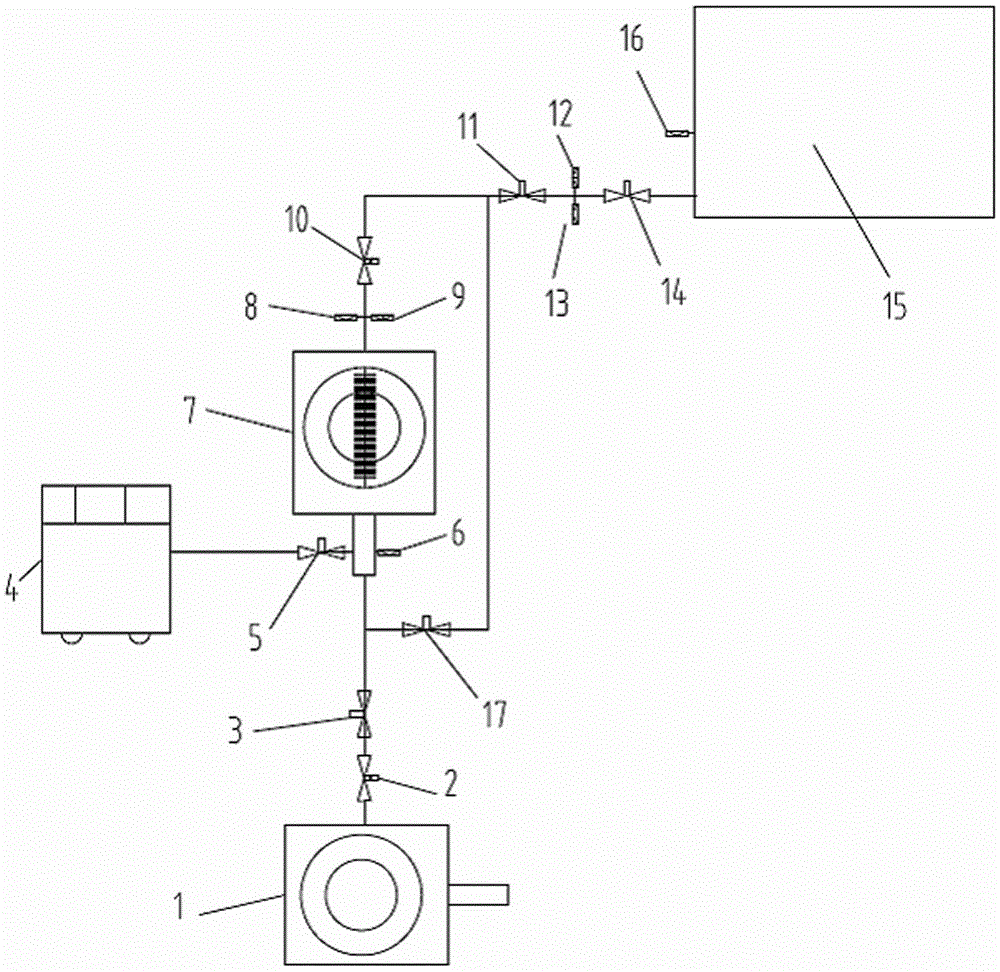

[0019] like figure 1 As shown, a molecular pump unit pre-evacuation and molecular pump leak detector integrated system includes a vacuum chamber 15, the vacuum chamber 15 is connected to a product vacuum valve 14 through a pipeline, and the product vacuum valve 14 is connected to a high vacuum valve through a pipeline Plate valve 11, the high vacuum damper valve 11 is connected to the high vacuum electromagnetic 10 through the pipeline, the high vacuum electromagnetic 10 is connected to the molecular pump 7 through the pipeline, and the molecular pump 7 is connected to the manual damper valve 3 through the pipeline, and the manual The baffle valve 3 is connected to the electromagnetic charging valve 2 through a pipeline, and the electromagnetic charging valve 2 is connected to the front-stage rotary vane pump 1, and the pipeline between the molecular pump 7 and the manual baffle valve 3 is connected to the leak detection valve 5 through a pipeline , the leak detection valve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com