Rotary vane pump/motor

A technology of rotary vane pumps and vanes, which is applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., and can solve problems such as low overall energy efficiency, large fluid energy loss, and tortuous road strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

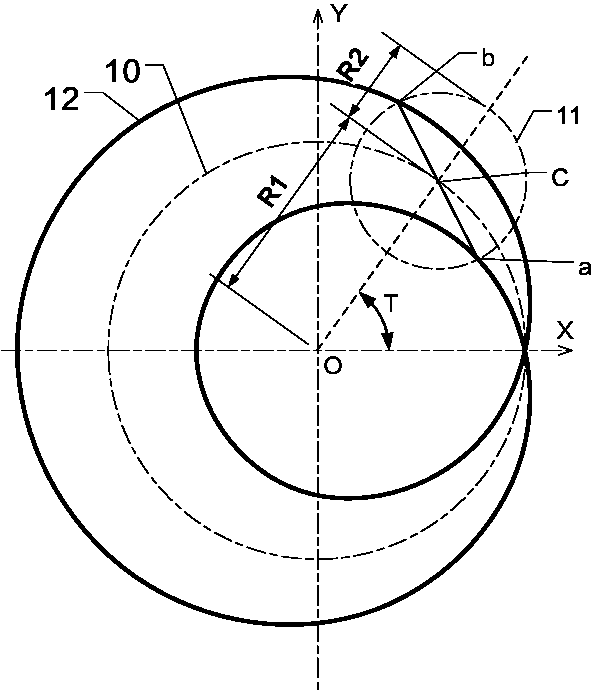

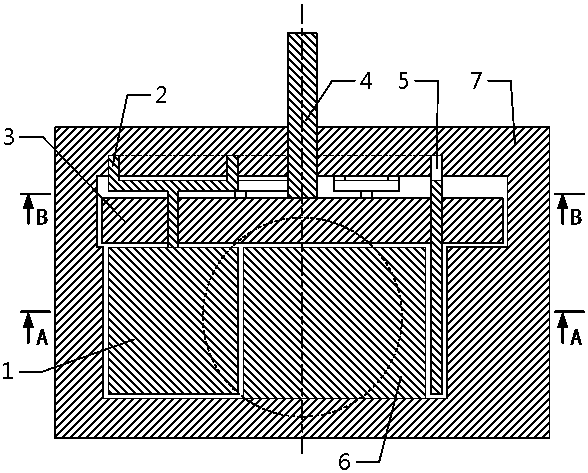

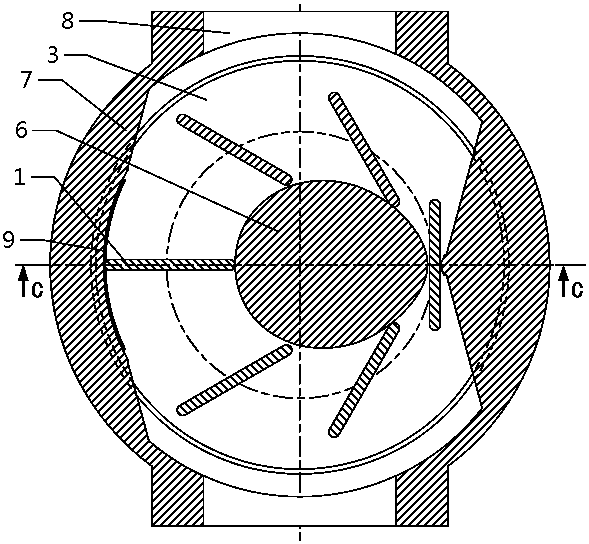

[0028] like figure 2 , image 3 , Figure 4 As shown, this embodiment provides a pump / motor with 6 uniformly distributed blades, including 6 blades 1, 6 synchronous claws 2, runner 3, power shaft 4, synchronous chute 5, shroud 6, Housing 7 and 2 fluid inlet and outlet ports 8 .

[0029] The blade 1 is movably connected with the runner 3, and the blade 1 can rotate relative to the runner 3; the top of each blade 1 is fixedly connected with the synchronous pawl 2, and the protrusion of the synchronous pawl 2 The slide bar is embedded in the groove of the synchronous chute 5; the runner 3 is fixedly connected with the power shaft 4; when the blade 1 is driven by fluid (motor working condition) or the runner 3 is driven by the When the power shaft 4 is driven (pump working condition), the blade 1 revolves with the runner 3, and at the same time, the protruding sliding rod of the synchronous pawl 2 connected to the blade 1 moves along the groove of the synchronous chute 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com