Pattern electroplating method for microstrip circuit

A graphic electroplating and microstrip circuit technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of electroplating deposition of functional layers in non-graphic areas, warping of electroplating functional layers, difficulty in controlling the adhesion of circuit film layers, etc. Achieve the effects of improving the cutting quality and yield, reducing the electroplating coating area, and reducing the phenomenon of film peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

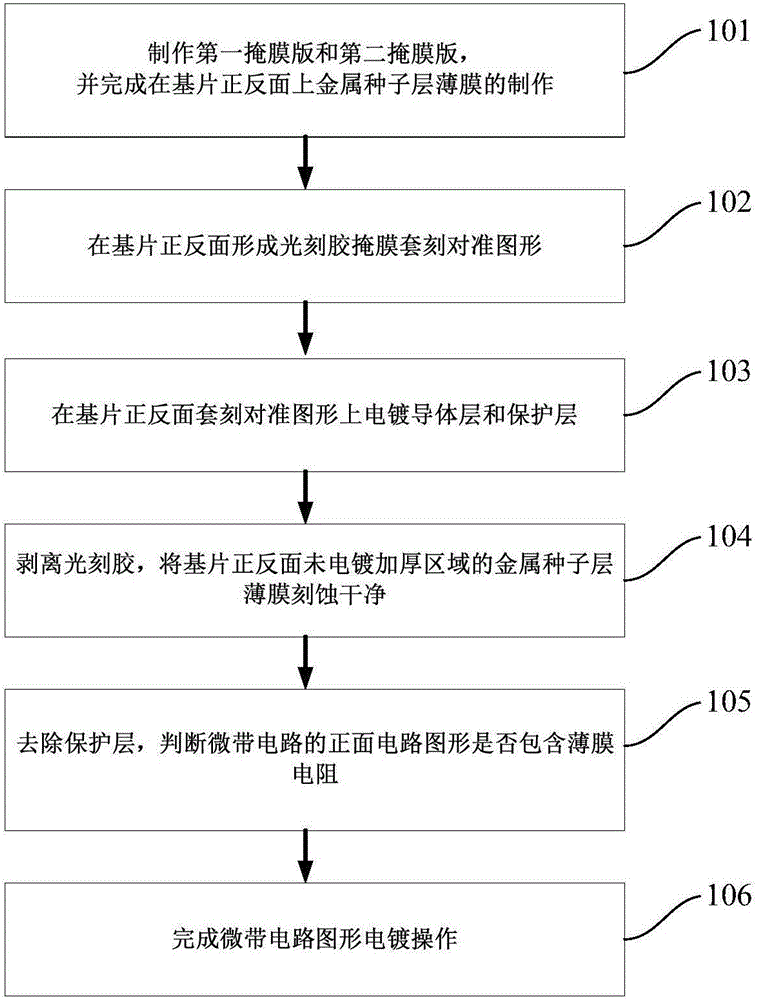

[0047] A method for pattern electroplating of microstrip circuits (such as figure 1 shown), follow the steps below:

[0048] Step 101: Use the front conductor pattern on the circuit, the scribe mark and the front alignment mark as the first information layer to make a first mask, and use the back conductor pattern and the back alignment mark on the circuit as the second information layer Making the second mask plate, and completing the making of the metal seed layer film on the front and back of the substrate.

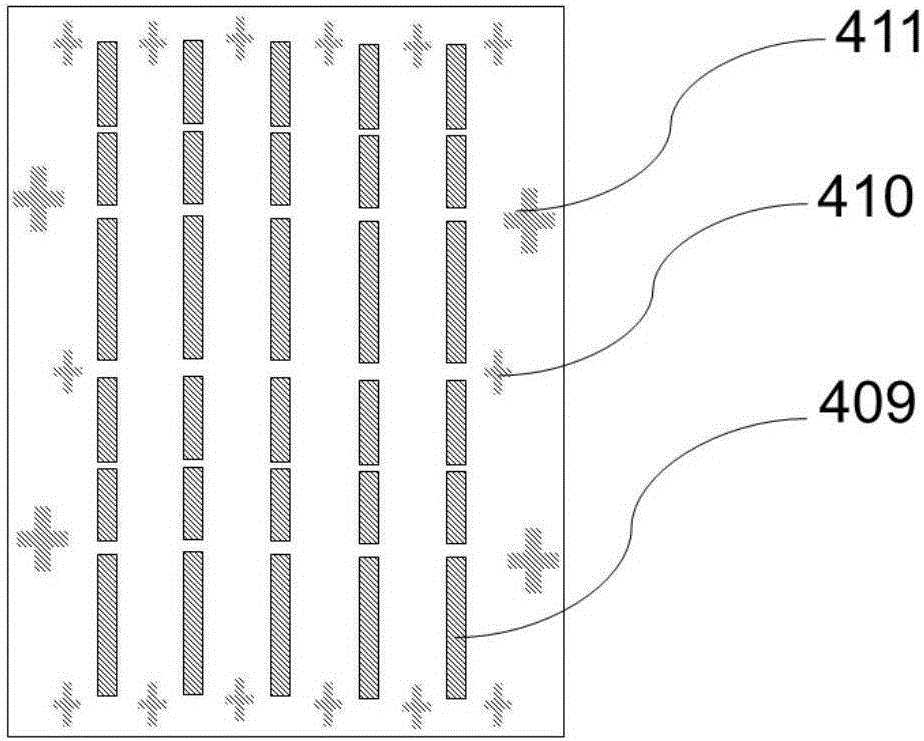

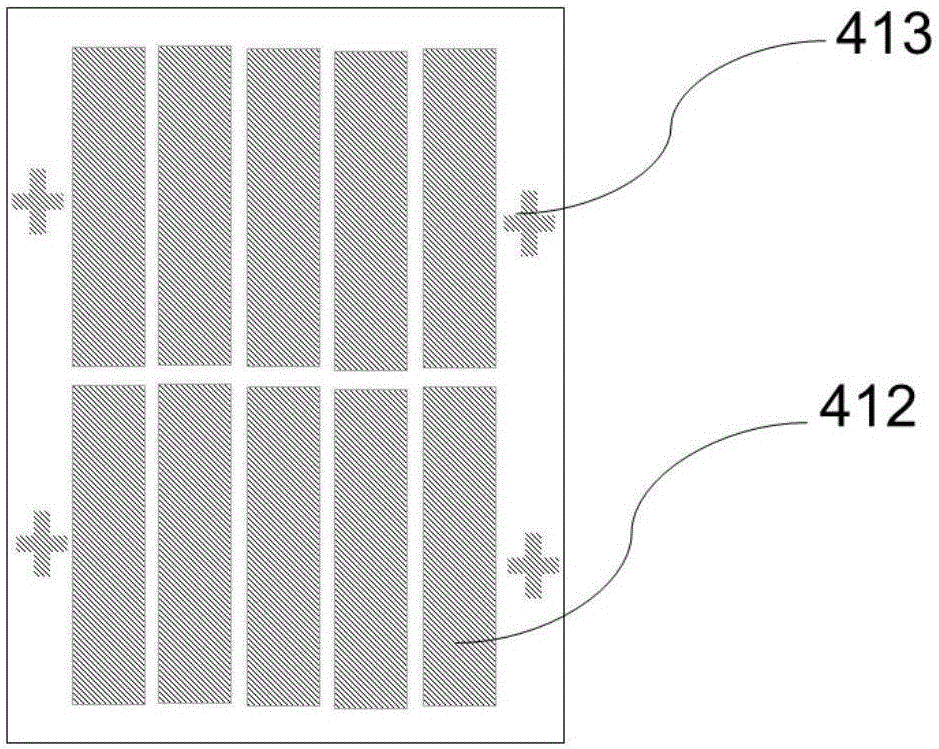

[0049] Specifically: use the front conductor pattern 409 of the circuit, the scribe mark 410 and the front alignment mark 411 as the first information layer to make the first mask (such as Figure 2a As shown), the reverse conductor pattern 412 and the reverse alignment mark 413 are used as the second information layer to make a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com