Production process of dipping agent bitumen

The technology of impregnating agent and asphalt is applied in the field of production technology of impregnating agent asphalt, which can solve the problems of high production cost, easy production of heavy-phase asphalt, complicated equipment structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

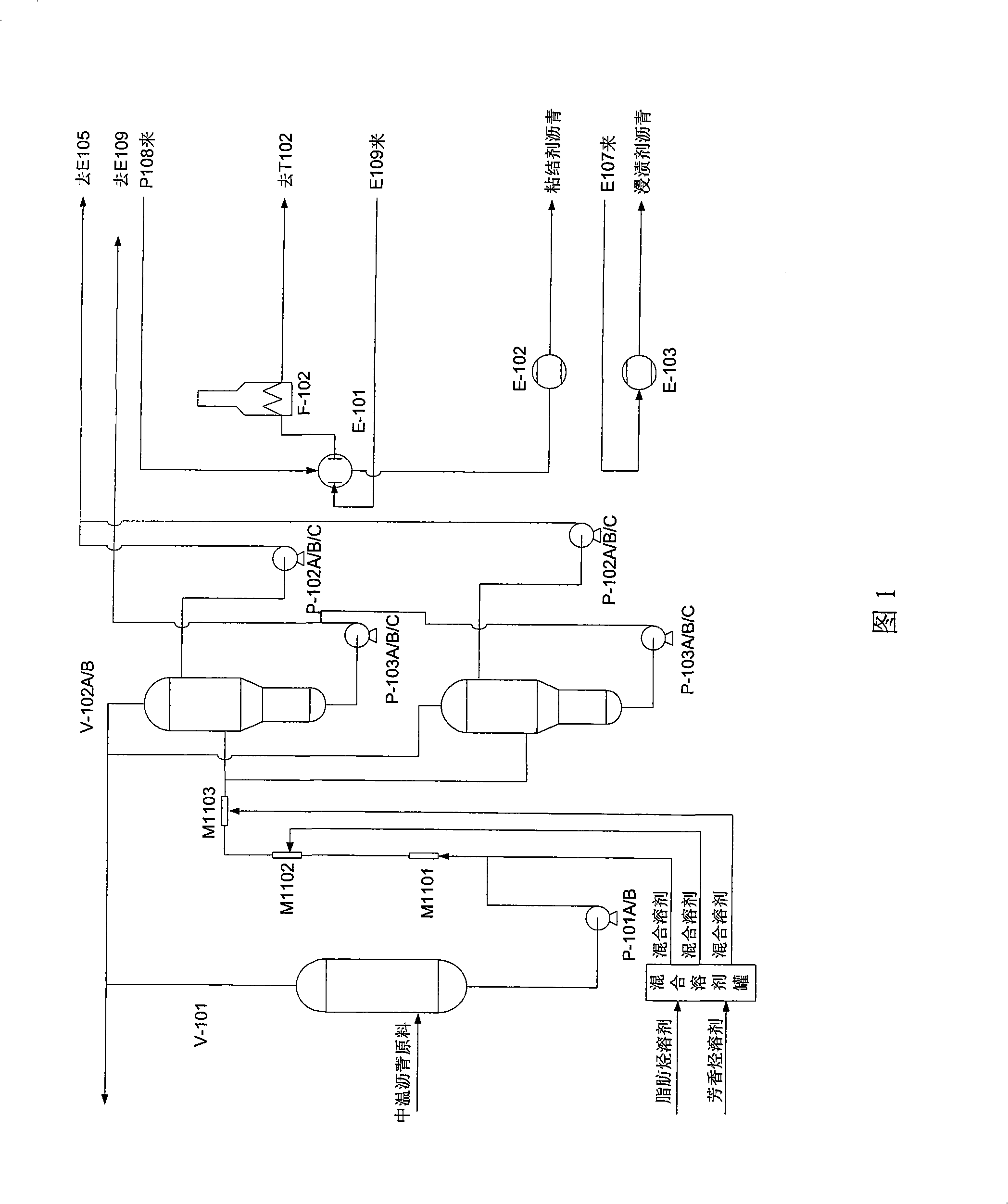

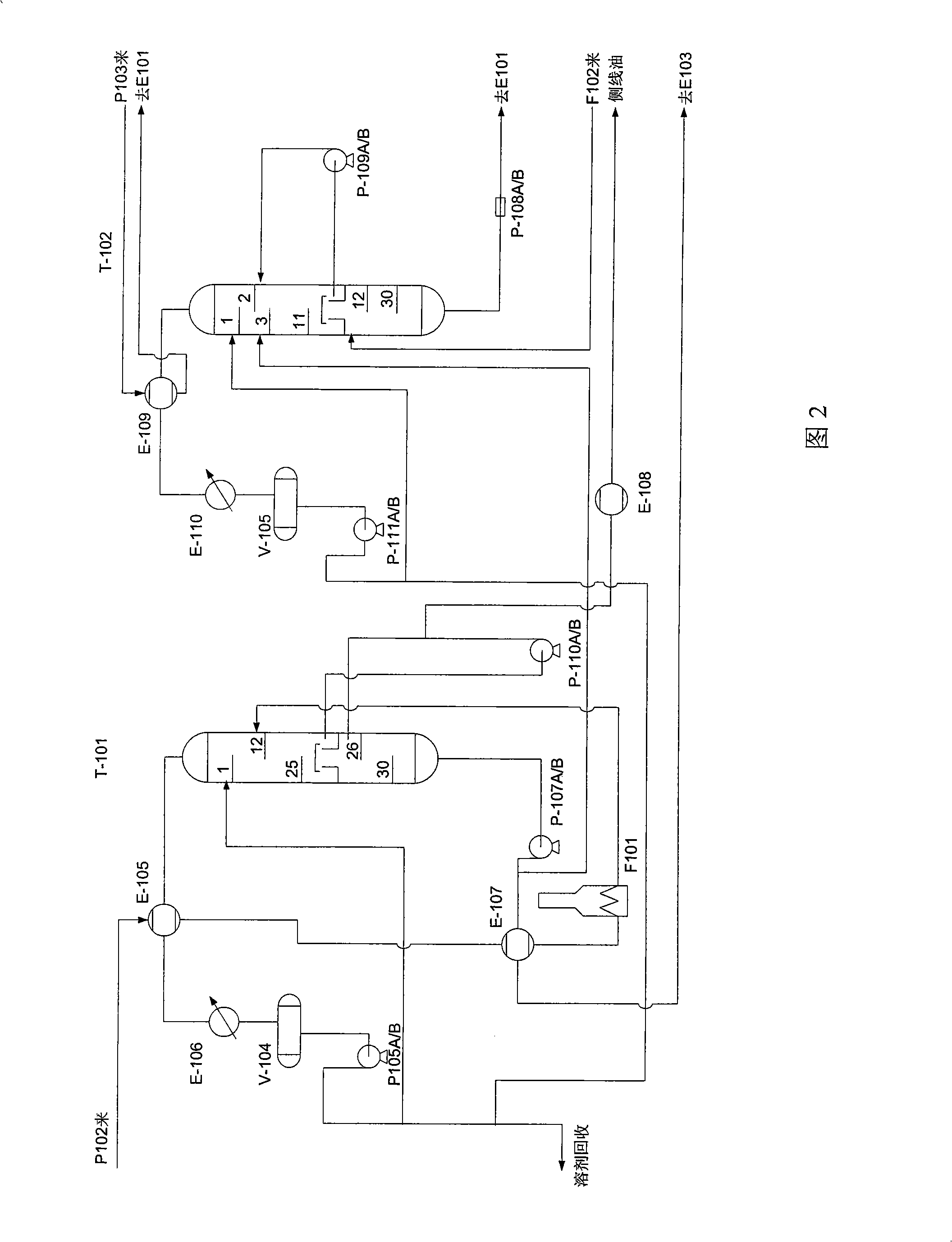

Method used

Image

Examples

Embodiment 1

[0074] Main equipment in the present embodiment technique comprises:

[0075] Raw material tank φ2800mm×11514mm;

[0076] The extraction tower is designed as a vertical two-stage cylindrical empty tower with a large diameter at the top and a small diameter at the bottom. The upper tower is φ4500mm×h(20000)mm, the lower tower is φ1200mm×h(6500)mm, the height of the transition section is 1800mm, and the material is 16MnR;

[0077] There are 30 trays in the stripping tower, and the material of the tower internals is 316C.

[0078] Using medium temperature coal tar pitch as raw material, its specifications are:

[0079] Softening point, ℃: 80~90

[0080] Toluene soluble matter, %: 15~25

[0081] Ash content, %: ≯0.3

[0082] Volatile matter, %: 58~68

[0083] Quinoline solubles, %: ≯10

[0084] The aliphatic hydrocarbon solvent used is kerosene, and its specification is:

[0085] Density(20℃)g / cm 3 : ≮0.775

[0086] Distillation range:

[0087] 1BP, ℃ Measured

[0088] ...

Embodiment 2

[0111] Coal tar soft asphalt is used as raw material, and its specifications are:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com