Three-dimensional printer having support material forming function and forming method

A technology of 3D printers and support materials, applied in 3D object support structures, manufacturing tools, additive processing, etc., can solve problems such as support material consumption, achieve weight reduction, cost reduction, and significant cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

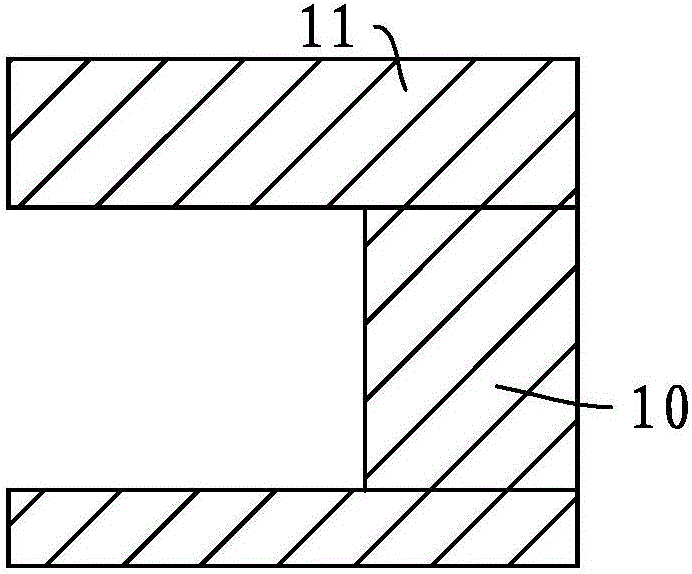

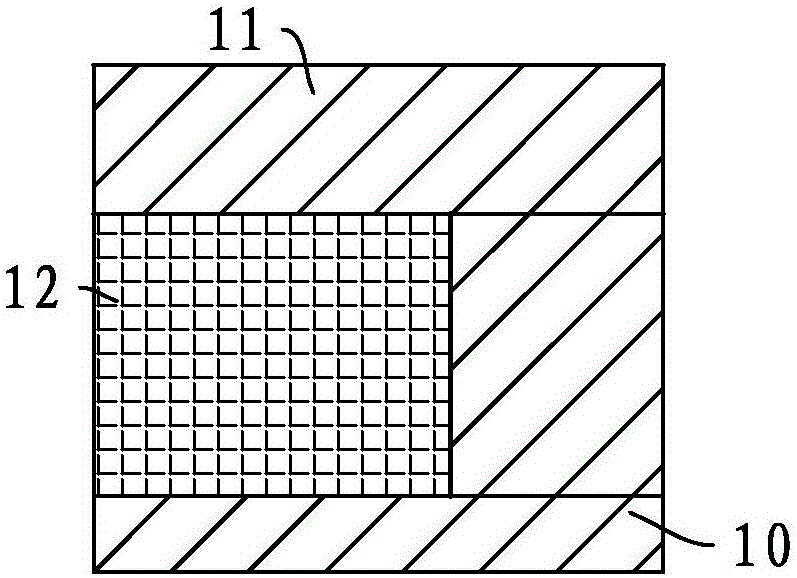

no. 1 example

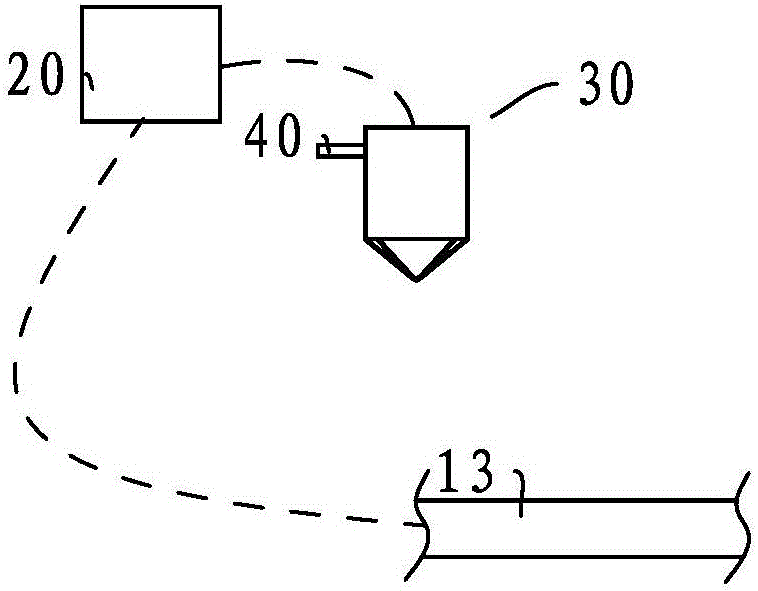

[0040] like image 3 As shown, this embodiment provides a three-dimensional printer with the function of forming support materials, which includes a print head assembly 30 , a printing platform 13 , a controller 20 and a first power unit 40 .

[0041] The print head assemblies 30 move independently in three-dimensional directions with respect to the printing platform 10 , respectively. The controller 20 is electrically connected to the print head assembly 30 and the printing platform 13 respectively. In one driving mode, the controller 20 drives the motor to rotate to provide power, and the motor drives the printing platform 13 or the print head assembly 30 to move through the transmission components. The first power unit 40 is loaded with foaming agent, and the first power unit 40 supplies the foaming agent into the melting chamber 33 to mix and melt the printing material.

[0042] like Figure 4 As shown, the print head assembly 30 includes a melting chamber 33 , and the ...

no. 2 example

[0052] The three-dimensional printer with the support material forming function of this embodiment is the same as that of the first embodiment, and only the differences will be described below. like Figure 5 As shown, the print head assembly includes a first print head 31 and a second print head 32 . The first printing head 31 is loaded with printing main material, and the first printing head 31 can move independently relative to the printing platform 13 along three-dimensional directions. The second print head 32 includes a melting chamber 33, the melting chamber 33 has a first through hole and a second through hole, and the printing support material enters the melting chamber 33 along the first through hole (side or top surface of the melting chamber), and the first power The unit delivers the blowing agent to the melting chamber 33 along the second through hole.

[0053] The first printing head 31 completes the printing steps of the main body portion 10 and the suspended...

no. 3 example

[0059] In this embodiment, a further improvement is made on the basis of the three-dimensional printer in the first embodiment. like Figure 6 As shown, it is a three-dimensional printer with a support material printing head provided in this embodiment, and the three-dimensional printer includes a printing head assembly and a printing platform 120 .

[0060] The printhead assembly is independently movable in three dimensions relative to the printing platform 120 . The controller 130 is directly or indirectly electrically connected to the print head assembly and the printing platform 120 respectively, and the controller can be a single-chip microcomputer or a chip processor or a computer or a PLC (programmable logic controller) program. The printhead assembly includes a first printhead 141 , a second printhead 142 and a third printhead 143 . The first printing head 141 is loaded with a printing subject material, and the first printing head 141 can move independently in three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com