Catalyst for complete methanation of synthesis gas from coal and preparation method thereof

A technology for complete methanation and coal-to-synthesis gas, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Lack of operating experience, small number of development and other problems, to achieve the effect of reducing the risk of pyrolysis carbon deposition, improving catalytic activity, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

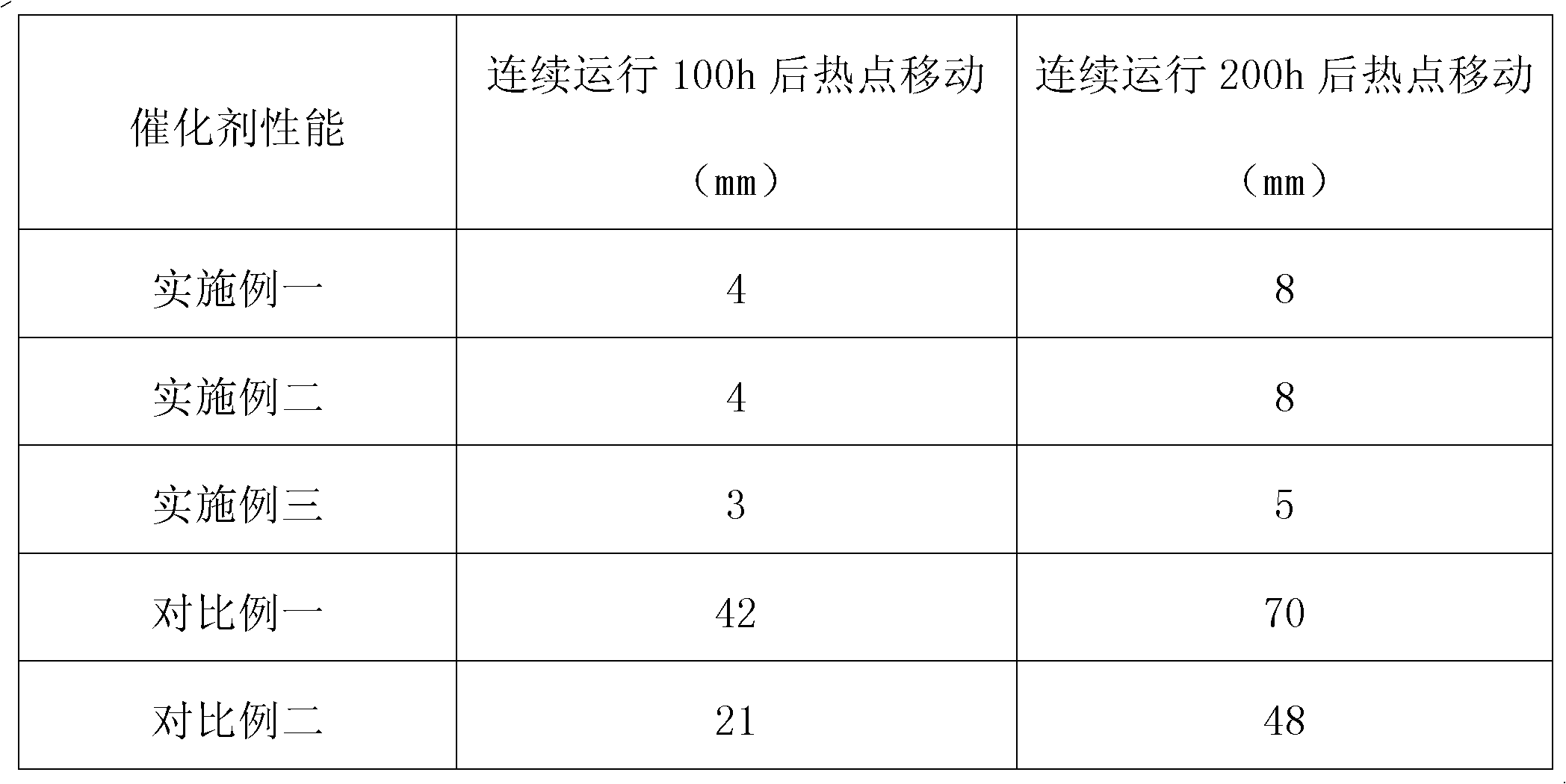

Examples

Embodiment 1

[0030] The mass percent content of each component of the present embodiment is: the NiO content is 60% of the total mass of the catalyst, the Al 2 o 3 The content is 20% of the total mass of the catalyst, and the content of MgO is 8% of the total mass of the catalyst; the first auxiliary rare earth metal oxide La 2 o 3 The content is 8% of the total mass of the catalyst, the content of the second auxiliary agent basic oxide CaO is 2% of the total mass of the catalyst, and the content of graphite is 2% of the total mass of the catalyst.

[0031] The preparation method of the present embodiment comprises the following steps:

[0032] Step 1, 8.53 grams of active Al 2 o 3 Mixed with 3.41 grams of MgO, roasted in a muffle furnace at a constant temperature of 1000°C for 6 hours to form a magnesium-aluminum spinel structure, and cooled for later use;

[0033] Step 2, take by weighing 99.62 grams of hydrated nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 7.18 grams of water and lanthan...

Embodiment 2

[0040] The mass percent content of each component of the present embodiment is: the NiO content is 55% of the total mass of the catalyst, the Al 2 o 3 The content is 25% of the total mass of the catalyst, and the content of MgO is 10% of the total mass of the catalyst; the first additive is rare earth metal oxide La 2 o 3 The content is 3% of the total mass of the catalyst and Sm 2 o 3 The content is 3% of the total mass of the catalyst, the content of the second auxiliary agent basic oxide BaO is 2% of the total mass of the catalyst, and the content of graphite is 2% of the total mass of the catalyst.

[0041] The preparation method of the present embodiment comprises the following steps:

[0042] Step 1, 10.66 grams of active Al 2 o 3 Mix it with 4.27 grams of MgO, and roast it in a muffle furnace at a constant temperature of 1000°C for 6 hours to form a magnesium-aluminum spinel structure, and cool it for later use;

[0043] Step 2, take by weighing 91.31 grams of hy...

Embodiment 3

[0050] The mass percentages of each component in this embodiment are: NiO content is 44% of the total mass of the catalyst, Al 2 o 3 The content is 30% of the total mass of the catalyst, and the content of MgO is 15% of the total mass of the catalyst; the first additive is rare earth metal oxide La 2 o 3 The content is 6% of the total mass of the catalyst, the content of the second auxiliary agent basic oxide CaO is 4% of the total mass of the catalyst, and the content of graphite is 1% of the total mass of the catalyst.

[0051] The preparation method of the present embodiment comprises the following steps:

[0052] Step 1, 12.80 grams of active Al 2 o 3 Mix it with 6.40 grams of MgO, roast it in a muffle furnace at a constant temperature of 1000°C for 8 hours to form a magnesium-aluminum spinel structure, and cool it for later use;

[0053] Step 2, take by weighing 73.07 grams of hydrated nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 5.39 grams of water and lanthanum nitrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com