Lead paste formula of energy storing accumulator and preparation method thereof

A storage battery and formula technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of poor over-discharge resistance and charge acceptance, and achieve the effect of meeting performance requirements, high cycle life, and high initial capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

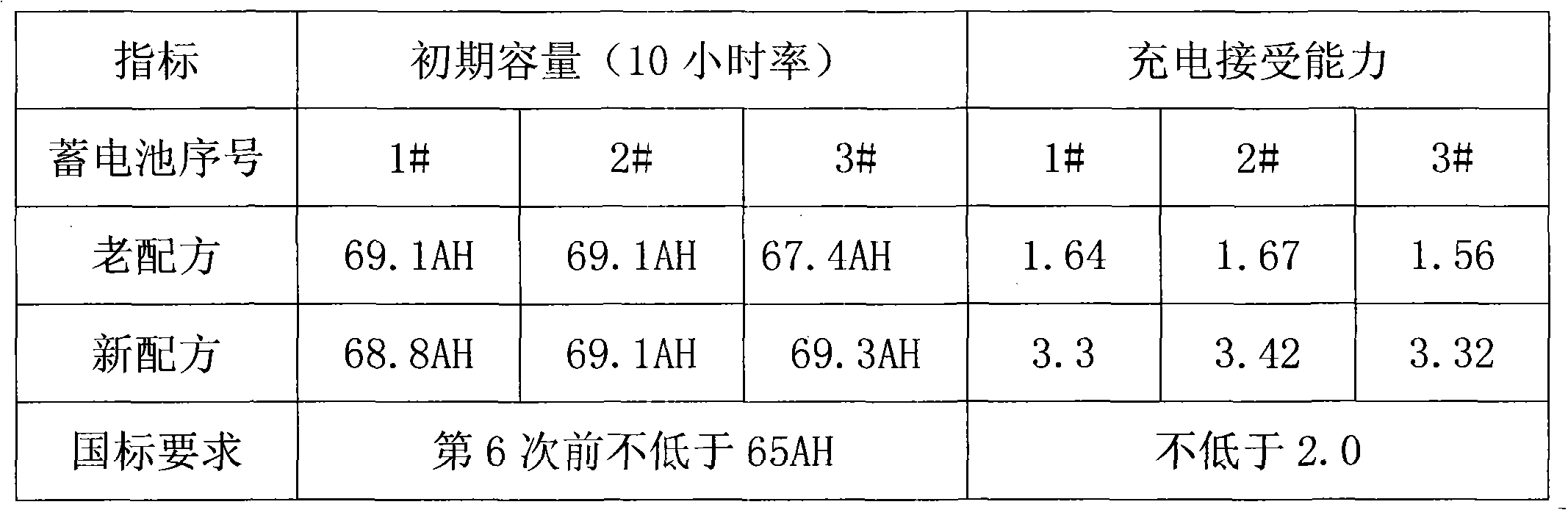

Examples

Embodiment 1

[0018] In this embodiment, the positive electrode paste formula is composed of the following raw materials by weight percentage:

[0019] Take 7% of dilute sulfuric acid, 10% of deionized water, 18% of red lead, 0.1% of colloidal graphite, 0.1% of stannous sulfate, 0.07% of polyester staple fiber, and the rest is lead powder.

[0020] Prepare as follows:

[0021] Mix the red lead, colloidal graphite, stannous sulfate and short polyester fibers together, then add them into the paste mixing machine together with lead powder, start stirring for 7 minutes, then add water evenly in 3 minutes, continue stirring for 5 minutes, Add dilute sulfuric acid evenly within 1 minute. While adding dilute sulfuric acid, turn on the inlet fan and circulating cooling water of the paste machine, and control the temperature at 50°C. After adding dilute sulfuric acid, continue stirring for 11 minutes to produce paste. The paste temperature is 44°C. about.

Embodiment 2

[0023] Take 7.5% of dilute sulfuric acid, 10.5% of deionized water, 23% of red lead, 0.2% of colloidal graphite, 0.15% of stannous sulfate, 0.08% of polyester staple fiber, and the rest is lead powder.

[0024] All the other implementations are as in Example 1.

Embodiment 3

[0026] Get 8% of dilute sulfuric acid, 11% of deionized water, 28% of red lead, 0.3% of colloidal graphite, 0.22% of stannous sulfate, 0.09% of polyester staple fiber, and the rest is lead powder.

[0027] All the other implementations are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com