Wear-resistant impact-resistant cable material for automobiles and preparation method thereof

An impact-resistant, cable material technology, applied in the field of cable materials, can solve problems such as obstacles to safe evacuation and fire fighting, poor wear resistance and impact resistance, and inability to meet market demands, to achieve improved service life, excellent wear resistance and Impact resistance, the effect of superior physical comprehensive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

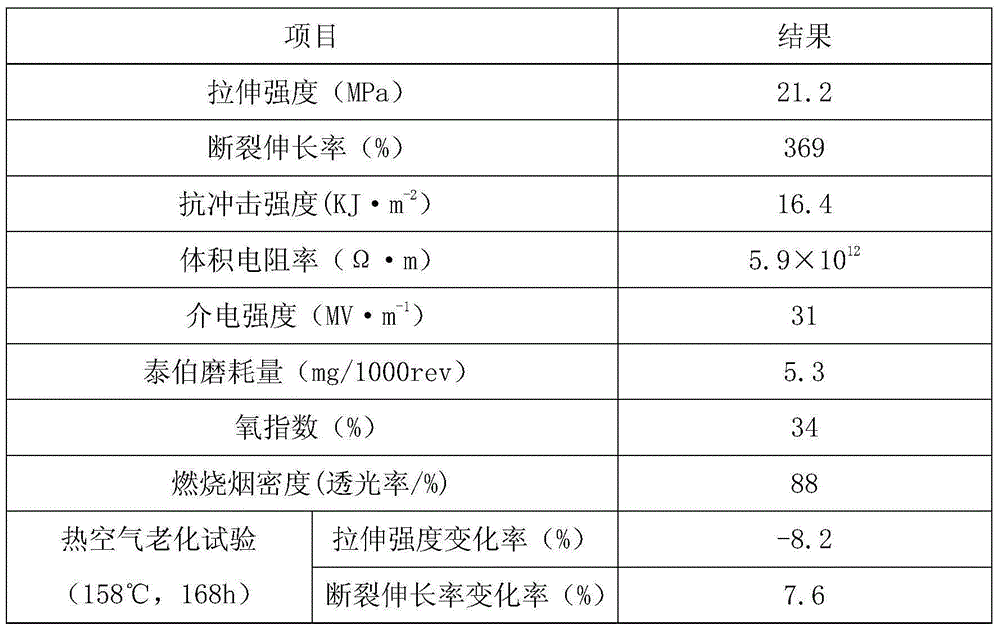

Examples

Embodiment Construction

[0018] A wear-resistant and impact-resistant cable material for automobiles, made of the following weight (kg) raw materials: nylon 6668, ultra-high molecular weight polyethylene 36, styrene-acrylonitrile-acrylate ternary block copolymer 18, polyethylene glycol Neopentyl glycol diacid 22, natural corundum 18, colloidal graphite powder 12, cobalt 2-ethylhexanoate 2.5, magnesium hypophosphite 4, Fischer-Tropsch wax 6, tetraoctyl pyromellitic acid 14, three (dodecyl) Mercaptan) antimony 3, composite flame retardant 18, antioxidant 10761.5, antioxidant 50571;

[0019] The preparation method of described composite flame retardant is as follows:

[0020] (1) Take colemanite, montmorillonite and magnesium molybdate in a ratio of 4:3:1 by mass, mix uniformly, pulverize, pass through an 80-mesh sieve, and then ball mill at 500r / min for 2h;

[0021] (2) Add water and stir the powder obtained by the above ball milling to prepare a suspension with a concentration of 40g / L, and then add a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com