Tin-doped photocatalysis formaldehyde sensing material, preparation method thereof and formaldehyde sensor

A sensing material, photocatalytic technology, applied in the direction of material resistance, etc., can solve the problems of not being able to distinguish ethanol well, material selectivity is not satisfactory, etc., and achieve improved detection limit, high selectivity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

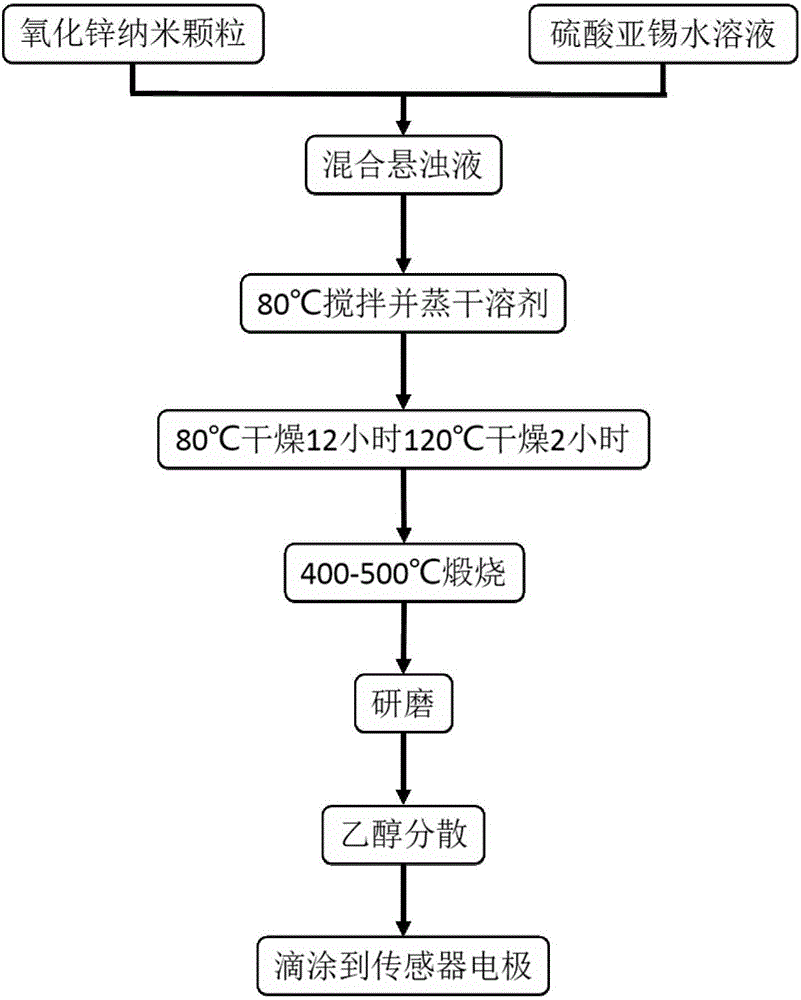

[0033] figure 1 It is a flow chart of the steps of the synthesis method of the photocatalytic formaldehyde sensing material of the present invention, comprising the following steps:

[0034] 1) Disperse pre-synthesized ZnO nanoparticles into a tin salt solution (such as SnSO 4 + deionized water);

[0035] 2) Evaporate the solution to dryness, preferably at 80-120°C, more preferably stir at 80°C until the solvent evaporates, then dry at 80°C for 12 hours and at 120°C for 2 hours to make the sample dry thoroughly;

[0036] 3) Calcining the obtained precipitate for a certain period of time at 400-500°C (the optimum calcination temperature is 450°C), and the original tin salt will generate tin oxide after calcination;

[0037] 4) Grinding the obtained solid product into powder and dispersing in ethanol solution to form a slurry.

[0038] Then, the obtained slurry is suspended-coated on the interdigitated electrode, and the solvent is dried to obtain the formaldehyde sensor we ...

Embodiment 1

[0040] Embodiment 1: Synthesis and testing of materials

[0041] Step 1: Synthesis of ZnO nanoparticles

[0042] 10.77gZnSO 4 ·7H 2 O (375 mmol) was dissolved in 25 mL deionized water. The solution was added dropwise to 50mL100g / L (1.36mmol / L) NH 4 HCO 3 The solution was stirred for 1 h in a water bath at 40°C. The supernatant was removed, and the precipitate was washed three times with 15 mL of deionized water each time, and then the precipitate was dried at 80 °C for 12 h and at 120 °C for 2 h. After baking, the samples were calcined in a muffle furnace at 500 °C for 2 h.

[0043] Step 2: Addition of tin element

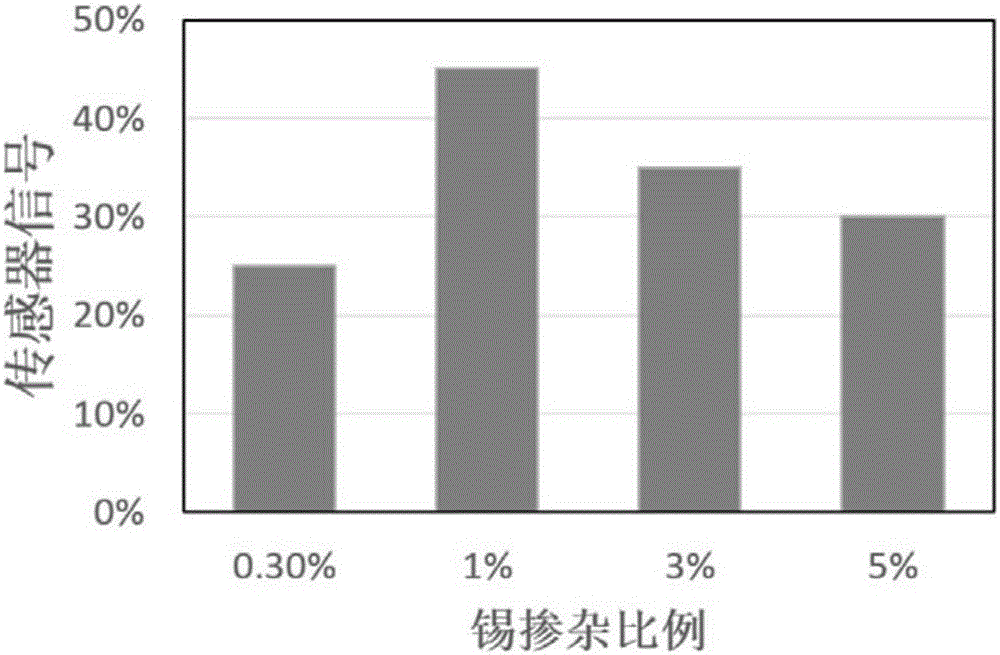

[0044] Weigh 0.4 g of pre-prepared ZnO nanoparticles and disperse them in 60 mL of tin salt solution (SnSO 4 0.007g), the solution was stirred at 80°C and the solvent was evaporated to dryness, then the precipitate was dried at 80°C for 12h and at 120°C for 2h. After this the precipitate was calcined at 450°C.

[0045] Step 3: Sensor Preparation

[0046]...

Embodiment 2

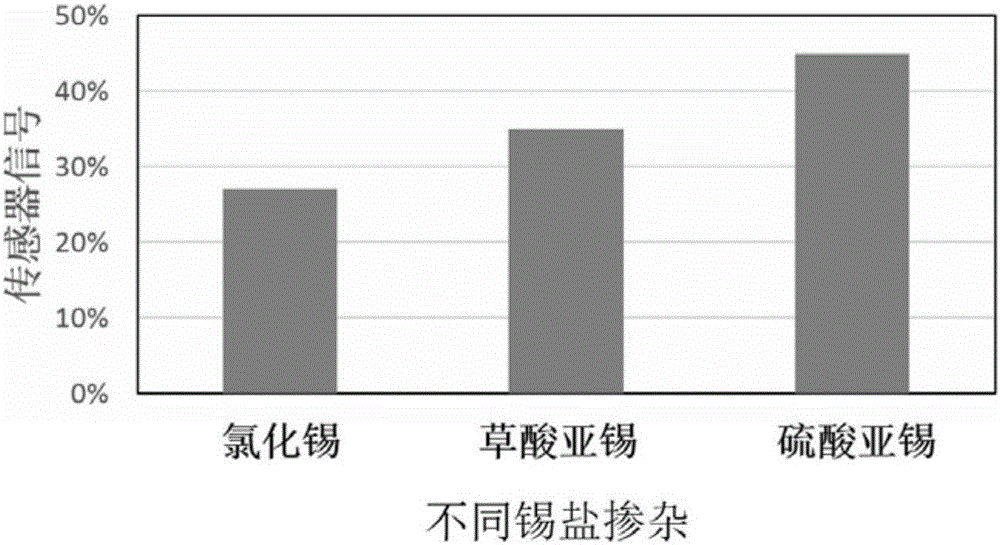

[0050] Embodiment 2: the introduction of different tin sources ( figure 2 )

[0051] a) SnCl 4 ·5H 2 o

[0052] Weigh 0.400g of synthesized ZnO particles and dissolve in 110ml of deionized water, and add 0.009g of SnCl to it 4 ·5H 2 O, then sonicate the solution for 5 minutes, stir and heat with a magnetic stirrer until the solvent is evaporated, put the obtained solid in an oven at 80°C for 8 hours, then adjust the temperature of the oven to 120°C for 2 hours, and then place it at 450 ℃ for 4 hours in a muffle furnace.

[0053] b) SnC 2 o 4

[0054] Weigh 0.400g of synthesized ZnO particles and dissolve them in 110ml of deionized water, and add 0.0056g of SnC 2 o 4 , then sonicate the solution for 5 minutes, stir and heat with a magnetic stirrer until the solvent is evaporated, put the obtained solid in an oven at 80°C for 8 hours, then adjust the temperature of the oven to 120°C for 2 hours, and then place it at 450°C Calcined in a muffle furnace for 4 hours.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com