Positive lead paste of lead-acid storage battery

A lead-acid battery, positive lead paste technology, applied in battery electrodes, circuits, electrical components and other directions, can solve problems such as performance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Lead-acid storage battery positive electrode lead paste of the present invention is made up of the raw material of following mass fraction: 1.4g / cm 3 Sulfuric acid 6.8-10%, deionized water 9-11%, red lead 5-16%, short fiber 0.05-0.06%, carbon fiber 0.10-0.15%, silicon dioxide 0.1%-0.3%, anisotropic graphite 0.1-0.4 %, stannous sulfate 0.05-0.28%, and the rest is lead powder. Wherein, the conductivity of the deionized water is less than or equal to 2 μs / cm. The silica is fumed silica with a specific surface area ≥ 200m 2 / g. Described red lead is the powder that passes 60 mesh sieves.

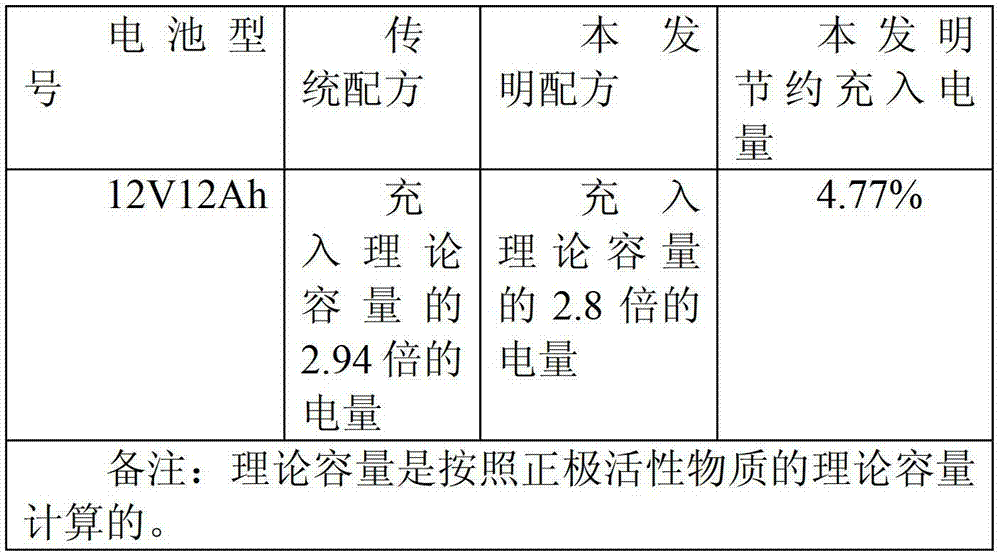

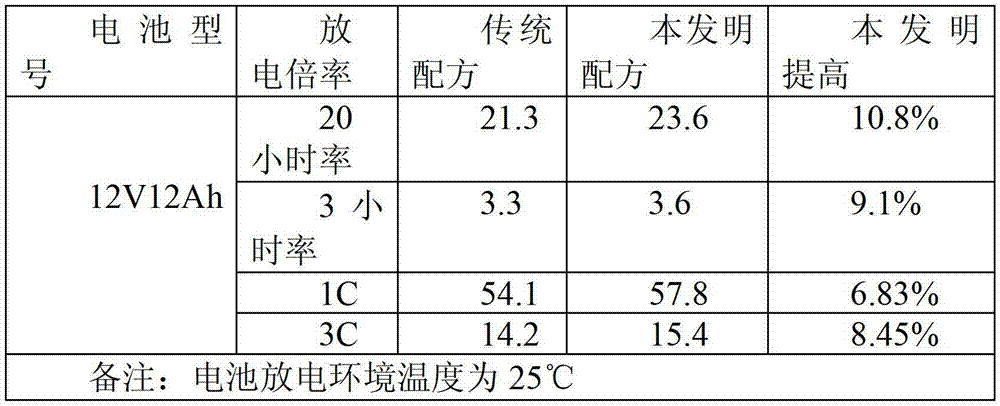

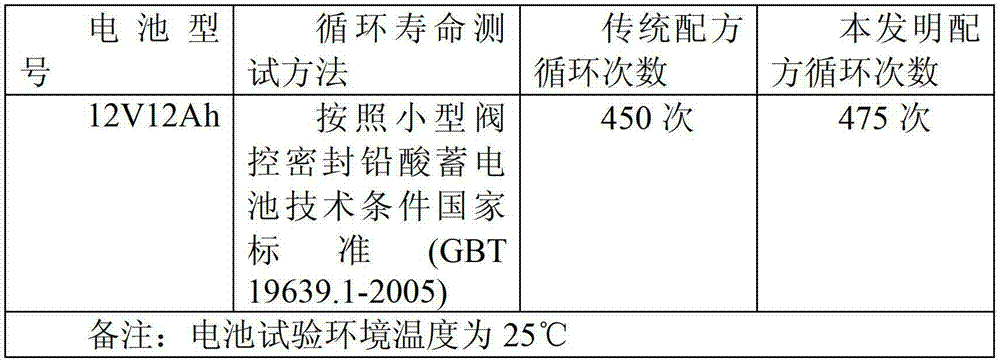

[0011] A conventional 12V12AH battery is used as a sample battery, and the traditional formula and the formula of the present invention are used for test comparison. After the battery is manufactured, test the initial capacity, weight specific energy and cycle life of 1C and 3C according to the national standard for technical conditions of small valve-regulated sealed lead-acid batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com