Method for preparing tin dioxide nano hollow sphere comprising nano rods and application in lithium battery

A tin dioxide and hollow sphere technology, applied in nanomaterials and their application fields, can solve cumbersome problems and achieve the effects of high purity, excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Add 0.054g of stannous sulfate into 50ml of ionized water, then transfer the aqueous solution of stannous sulfate into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, conduct a hydrothermal reaction at 200°C for 1 day, and wash and filter the obtained product with deionized water 3 times, drying at 70°C for 4 hours to obtain high-purity SnO composed of nanorods 2 nano hollow spheres.

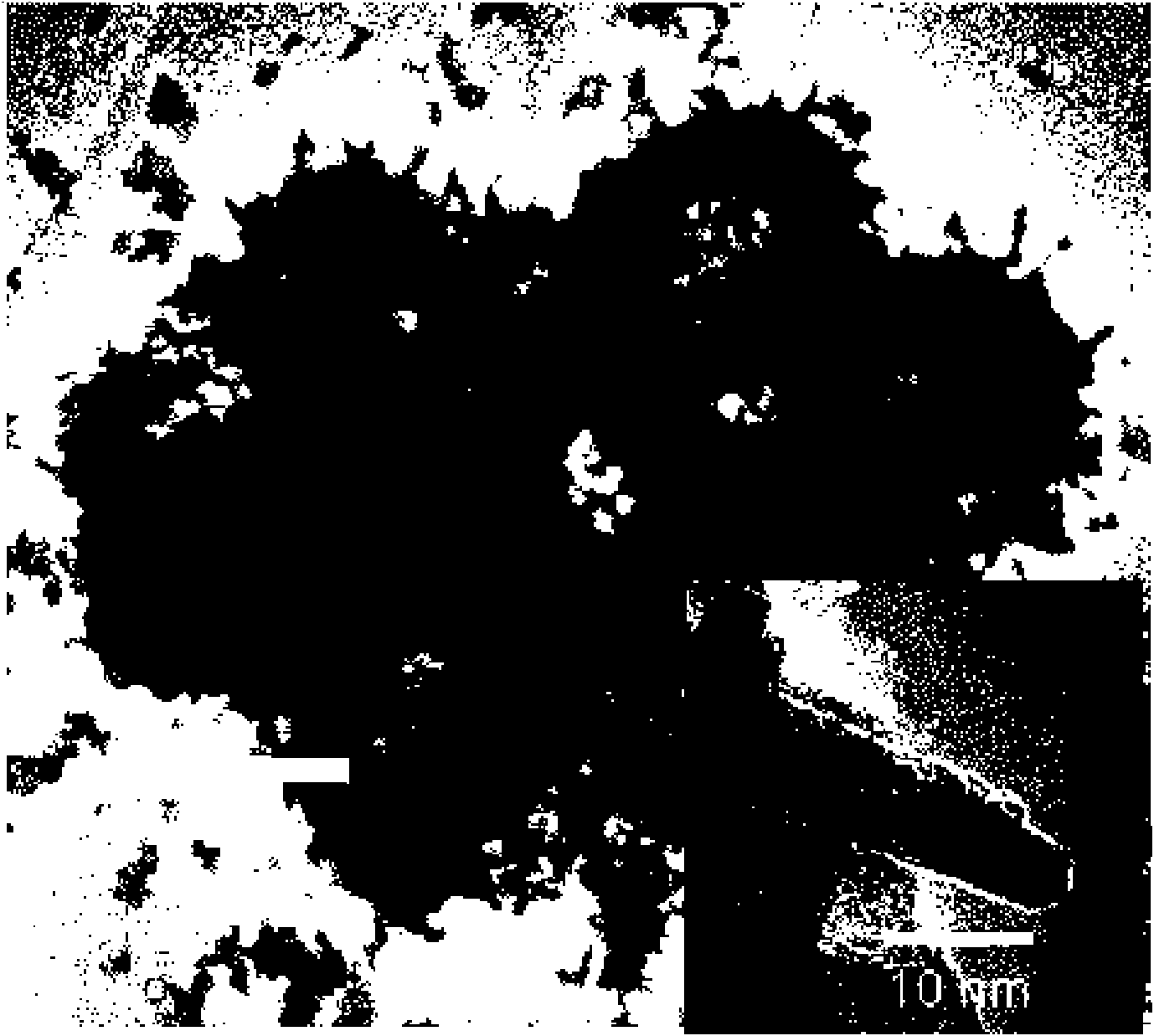

[0013] From figure 1 It can be seen from the scanning electron microscope that the as-prepared SnO 2 It is a spherical structure composed of many fine nanorods, and these spherical structures are aggregated together. figure 2 The TEM further confirmed such a structure. From figure 2 It can be observed that these spherical structures are hollow and about 200 nm in diameter. On the spherical shells of these hollow spheres are some SnO with a diameter of about 5-10nm and a length of tens of nanometers. 2 Nano stave.

[0014] SnO 2 The assembly process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com