Lead-acid storage battery electrolyte solution and preparation method thereof

A technology of lead-acid battery and preparation method, which is applied in the field of electrolyte, can solve the problems of short life of the battery, achieve the effects of prolonging life, avoiding capacity decay in the early stage, and avoiding loosening and degreasing of living things

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below.

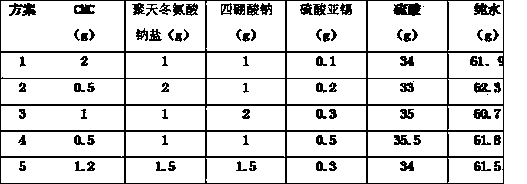

[0017] The ratio of each material in the electrolyte:

[0018]

[0019] Option 1: Due to the small space in the battery design, in order to ensure sufficient lead, the only solution is to reduce the electrolyte space, and the amount of electrolyte determines the performance of the battery; when the battery is used in a high temperature environment, the battery loses water quickly. The reason for this is to minimize the loss of water in the electrolyte formula, and it is better to add CMC to the upper limit.

[0020] Solution 2: The battery is used for a long time under the condition of over-discharge, and the charging is not timely, and it is easy to generate large particles of lead sulfate; the battery is used in a low-temperature environment, and the negative plate is easy to over-discharge and generate a large amount of lead sulfate, which is not easy to convert into active substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com