Ceramic substrate and copper clad foil low-temperature connecting soldering paste and production process thereof

A technology for ceramic substrates and production processes, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of high connection temperature, high void ratio, and large thermal stress, to simplify the process, ensure joint quality, and reduce thermal stress. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0026] The thickener content is 9% in embodiment 4; The thickener content is low in embodiment 1,5,6,7, is 4%. In embodiment 3, 4, 5, 7, adopted three component solvents.

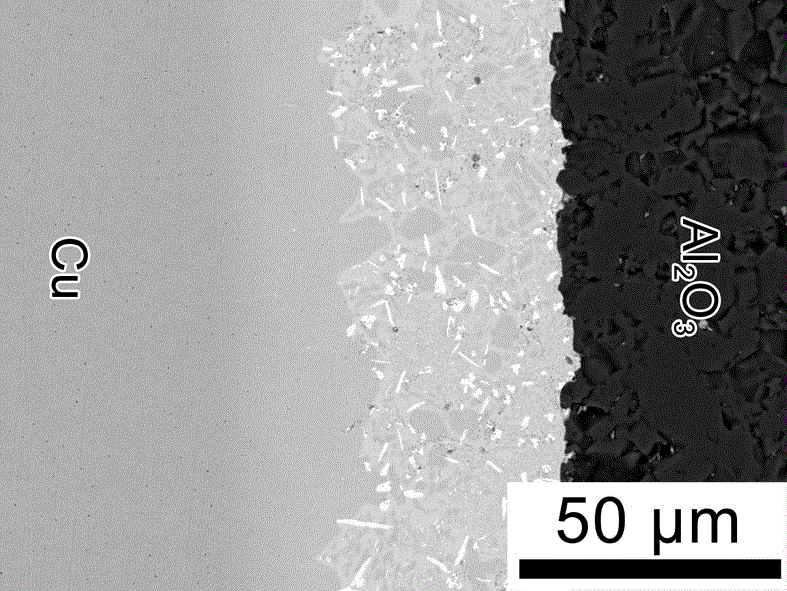

[0027] The test found that the content of Sn and Ti in Example 3 was moderate, and the melting point was lowered while ensuring a good connection with the ceramic side. The three-component solvent composed of terpineol, diethylene glycol monobutyl ether and diethylene glycol methyl ether can adapt to With different combinations of thixotropic agents and activators, the viscosity of solder paste is moderate. The microstructure of the ceramics and copper interface connected by the solder paste produced by the process in Example 3 is shown in figure 1 .

Embodiment 1

[0029] The invention relates to a low-temperature solder paste for connecting a ceramic substrate with copper, which is composed of solder powder and flux paste. Among them, in the solder powder: the mass fraction of Ag is 26%, the mass fraction of Cu is 30%, the mass fraction of Ti is 4%, and the mass fraction of Sn is 40%. The solder paste is mainly composed of the following materials in weight percentage:

[0030] Rosin: water white rosin 35%

[0031] Solvent: 20% terpineol, 25% 2-ethyl-1,3-hexanediol

[0032] Thixotropic agent: polyamide wax 6%

[0033] Active agent: Alkylphenol polyoxyethylene ether 8%

[0034] Corrosion inhibitor 2%

[0035] Thickener 4%

[0036] The production process of the low-temperature solder paste connecting the ceramic substrate with copper mainly includes the following steps:

[0037] (1) weigh 40g solder powder and place it in a ball mill jar, wherein the mass fractions of the four elements tin, silver, copper and titanium are as mentione...

Embodiment 2

[0045] The invention relates to a low-temperature solder paste for connecting a ceramic substrate with copper, which is composed of solder powder and flux paste. Wherein in the solder powder: the massfraction of Ag is 20%, the massfraction of Cu is 40%, the massfraction of Ti is 5%, the massfraction of Sn is 35%, and the flux paste is mainly made up of following weight percent materials:

[0046] Rosin: dimerized rosin 33%

[0047] Solvent: terpineol 20%, diethylene glycol monobutyl ether 25%

[0048] Thixotropic agent: polyamide 6%

[0049] Active agent: Alkylphenol ethoxylate 4%, Nonylphenol ethoxylate 4%

[0050] Corrosion inhibitor 2%

[0051] Thickener 6%

[0052] The production process of the low-temperature solder paste connecting the ceramic substrate with copper mainly includes the following steps:

[0053](1) weigh 40g solder powder and place it in a ball mill jar, wherein the mass fractions of the four elements tin, silver, copper and titanium are as mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com