Low-cost anti-aging brazing filler material used for electronic packaging and preparation method thereof

An electronic packaging, low-cost technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of many types of added elements, complex metallurgical preparation, melting point of solidification cracks, etc., to achieve excellent solderability and comprehensive mechanical properties , The preparation process is simple, and the effect of reducing the generation of solidification cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: A low-cost anti-aging solder for electronic packaging in this embodiment consists of 0.60% to 0.79% Ag, 0.50% to 0.90% Cu, 0.02% to 0.20% Ni, and 2.10% -4.00% Bi and the balance Sn.

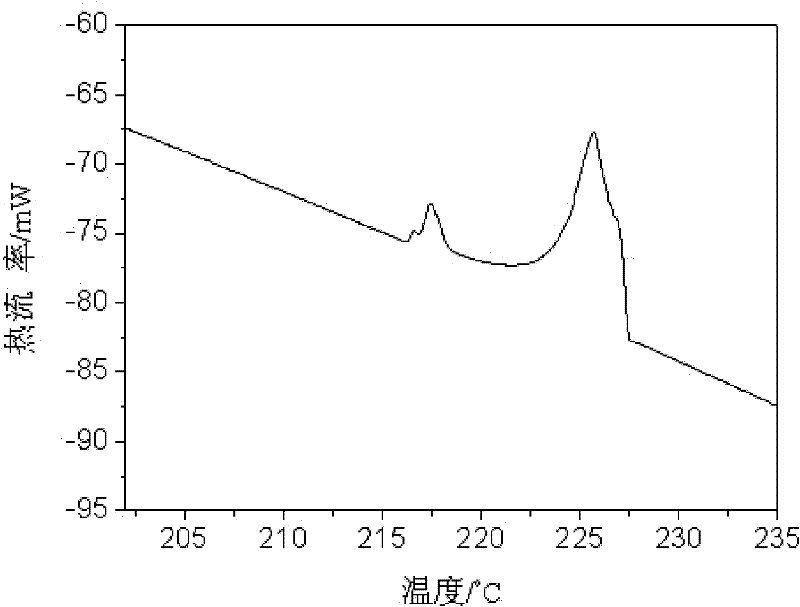

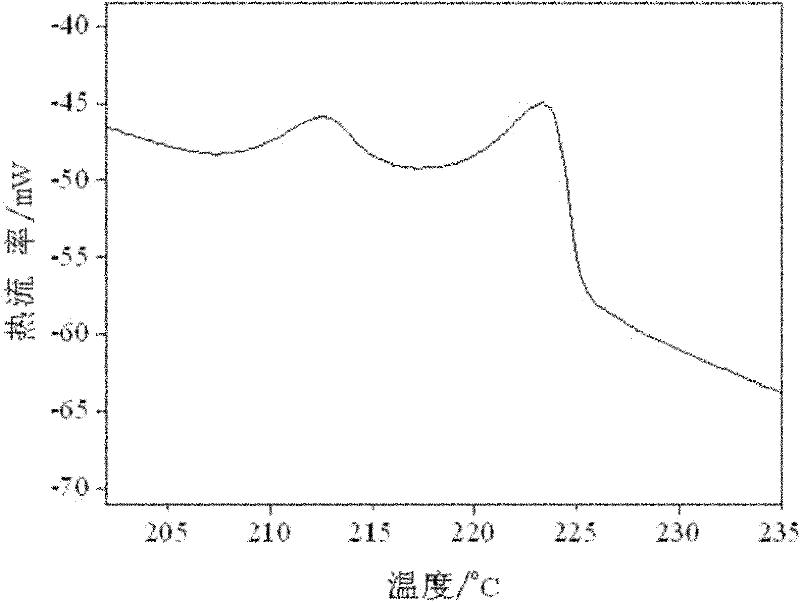

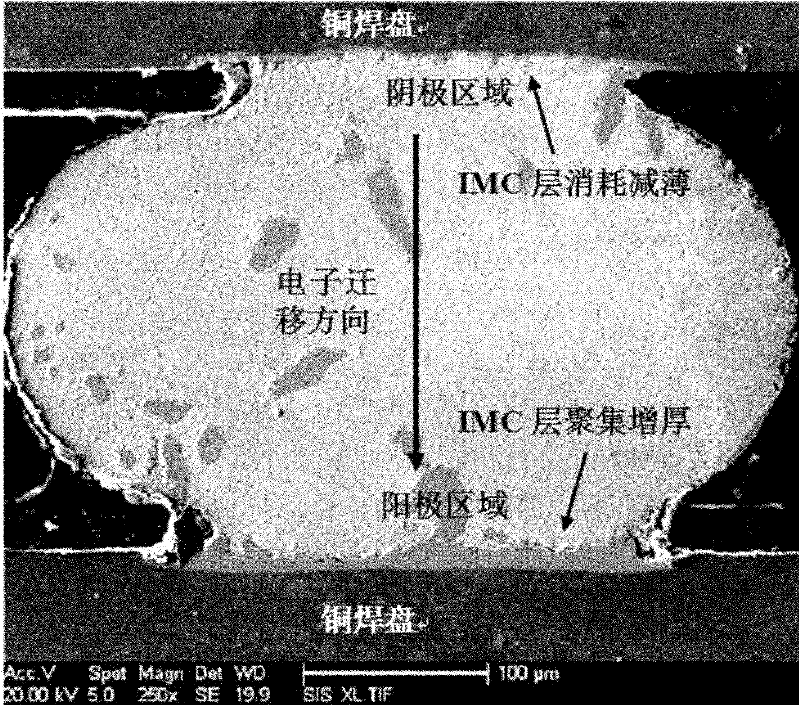

[0010] The low-cost anti-aging solder for electronic packaging in this embodiment reduces the cost of the solder and at the same time obtains excellent solderability and comprehensive mechanical properties. The silver content of the solder is 0.60% to 0.79%, and the silver content is relatively low. Melting point is only 205℃~219℃, good wettability and good solderability. Compared with SAC305 solder, its cost can be reduced by 30% to 43%, the melting point and wettability of the solder are improved, the shear strength of the brazed joint is increased by more than 40%, and the high temperature aging resistance is obviously improved. Compared with SAC0307 solder, the melting point and wettability of the solder have been significantly improved, and the shear strength of the bra...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the low-cost anti-aging solder for electronic packaging is composed of 0.63% to 0.75% Ag, 0.60% to 0.80% Cu, and 0.05% to 0.18% by mass percentage. Ni, 2.30% to 3.50% Bi and the rest of Sn.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the low-cost anti-aging solder for electronic packaging is composed of 0.70% Ag, 0.70% Cu, 0.10% Ni, 2.80% Bi and the rest amount of Sn composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com