Patents

Literature

31results about How to "Good high temperature aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

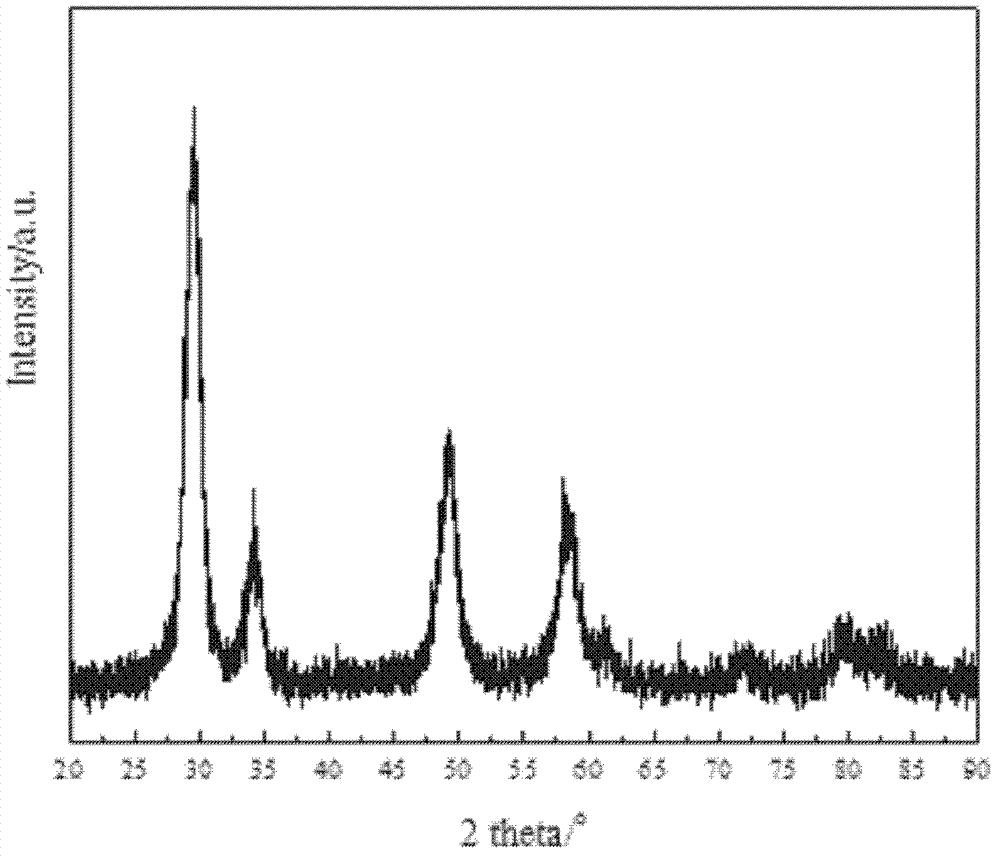

Nanometer ceria-zirconium solid solution and preparation method thereof

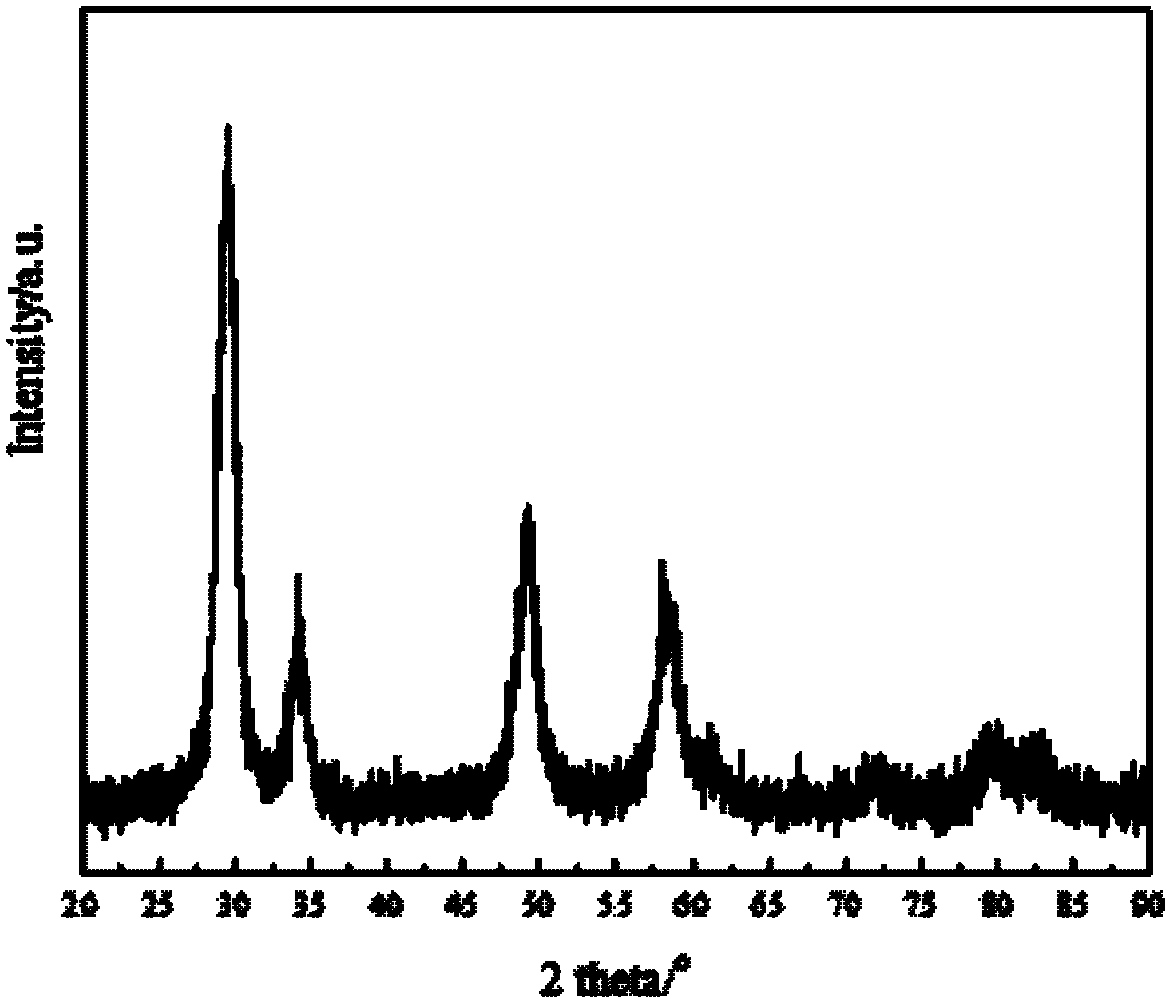

ActiveCN102580719ALarge apertureLarge hole volumeDispersed particle separationIncinerator apparatusRare earthPore diameter

The invention aims to disclose a nanometer ceria-zirconium solid solution and a preparation method thereof. The nanometer ceria-zirconia solid solution comprises the following components according to weight percent: 15 to 65% of cerium oxide, 12 to 70% of zirconia and 10 to 30% of compound oxide composed of other tombarthite oxide except for ceria and zirconium. Compared with the conventional products, the nanometer ceria-zirconium solid solution obtains larger pore diameter and pore volume through modification of a structural directing agent and a dispersing agent, has a favorable capability of resisting high temperature and ageing, and has the advantages of high oxygen storage capability and high speed in oxygen storage and discharge, so that the purposes of the invention are achieved.

Owner:方复(上海)新材料科技有限公司

Composite aluminium, cerium and zirconium oxide catalytic material and method for producing same

ActiveCN102824904AEnhanced interactionGuaranteed uniformityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPore diameterTemperature resistance

The invention aims to disclose a composite aluminium, cerium and zirconium oxide catalytic material and a method for producing the same. The composite aluminium, cerium and zirconium oxide catalytic material is a composite oxide which consists of 15-30% of cerium oxide, 5-20% of zirconium oxide, 50-75% of aluminium oxide and 0-5% of other rear earth oxides expect cerium by weight. Compared with the prior art, the aluminium oxide is subjected to surface treatment, on one hand, the interaction of the aluminium oxide and the cerium and zirconium-base composite oxides is enhanced; and on the other hand, the uniformity of the aluminium oxide and the cerium and zirconium-base composite oxides is fully ensured; through the modification of a structural directing agent and a dispersing agent, the pore diameter and pore volume of the composite aluminium, cerium and zirconium oxide catalytic material are further improved, and good temperature resistance and aging resistance are obtained; and moreover, the composite aluminium, cerium and zirconium oxide catalytic material has the advantages of high oxygen storage capability and high oxygen storage and release velocities, so the purpose of the invention is realized.

Owner:上海华明高纳稀土新材料有限公司

Production process of Japanese paper adhesive tape base paper

The invention relates to a production process of Japanese paper adhesive tape base paper. The production process includes steps: a pure wood pulp is subjected to defibering and pulping to obtain size with concentration to be 3.5-4.0% and beating degree to be 18-20 oSR; b polyester chemical fibers are subjected to defibering and mixed with the size obtained from the step a to obtain mixed size with concentration to be 2-2.5%, wherein the filling quantity of polyester chemical fibers is 2-3% of the total mass of the mixed size; c wet strength agents and polyethylene oxide are filled into the mixed size and evenly mixed, then a net portion is formed through inclined wire papermaking, and after squeezing for dehydration, drying in a vat, reeling and rewinding slitting, a piece of papermaking base paper is obtained; and d the base paper is soaked by aid of a coating machine and then is coated with adhesives, the gluing amount is controlled to be in a 10-12g / m<2> range, and after drying, reeling and slitting rewinding, the Japanese paper adhesive tape base paper is obtained. The Japanese paper adhesive tape base paper is soft, high in longitudinal tensile strength and good in water seepage resistance and high temperature ageing resistance.

Owner:杭州新兴纸业有限公司

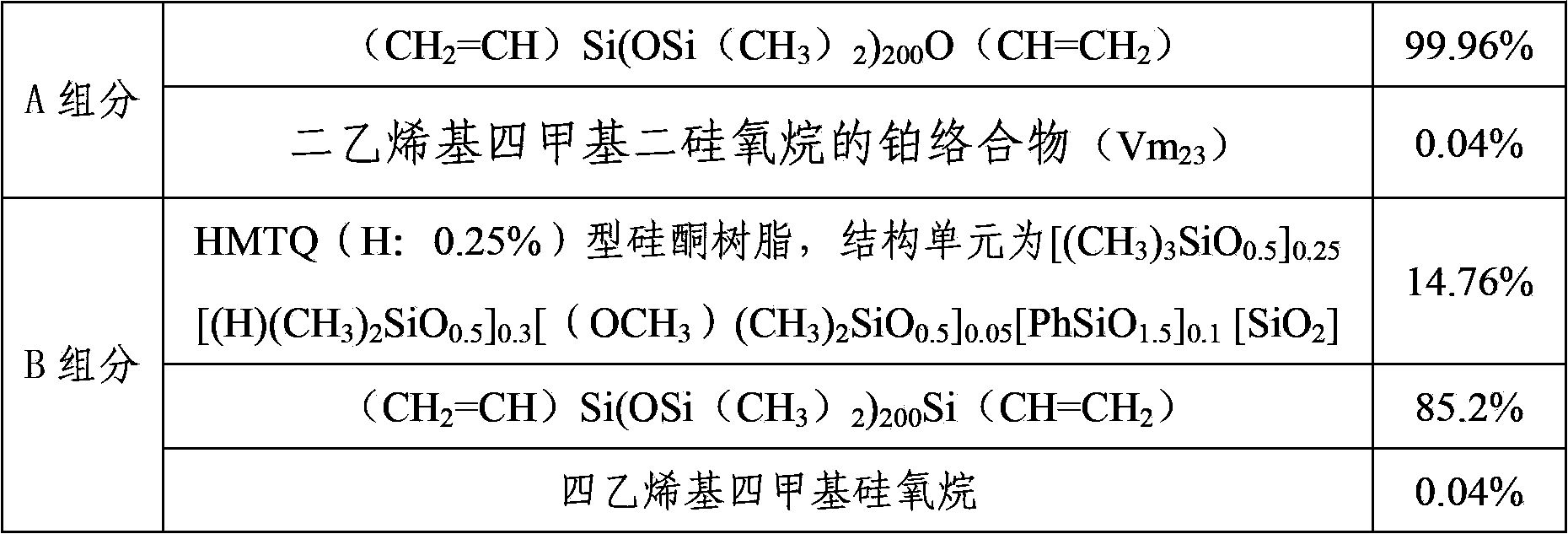

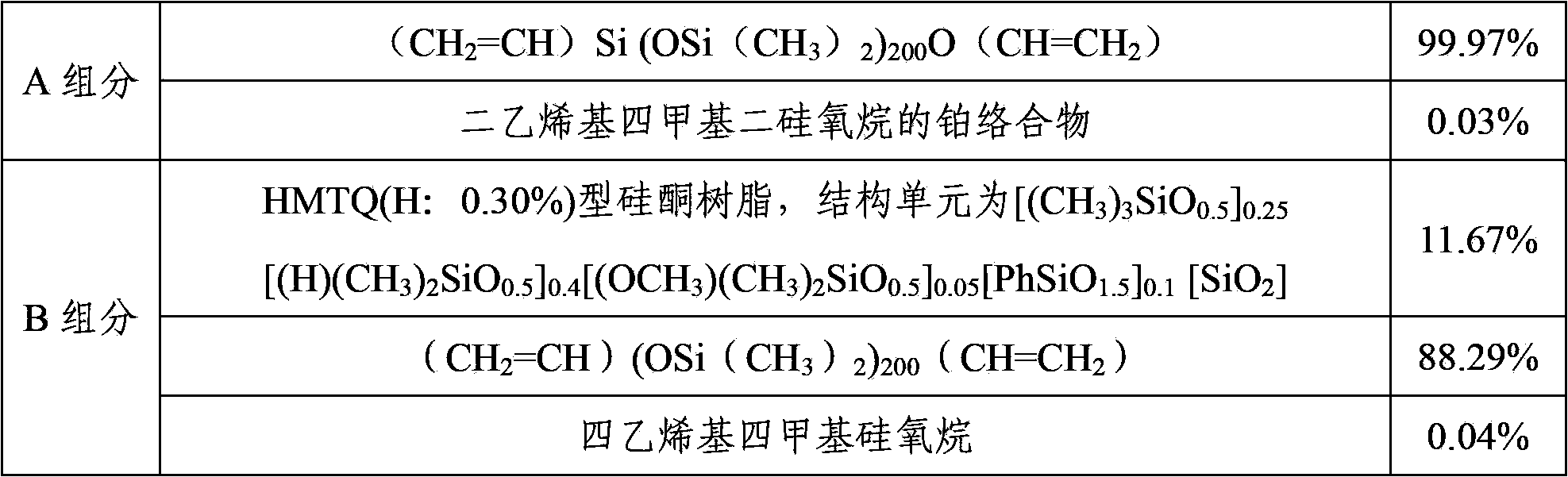

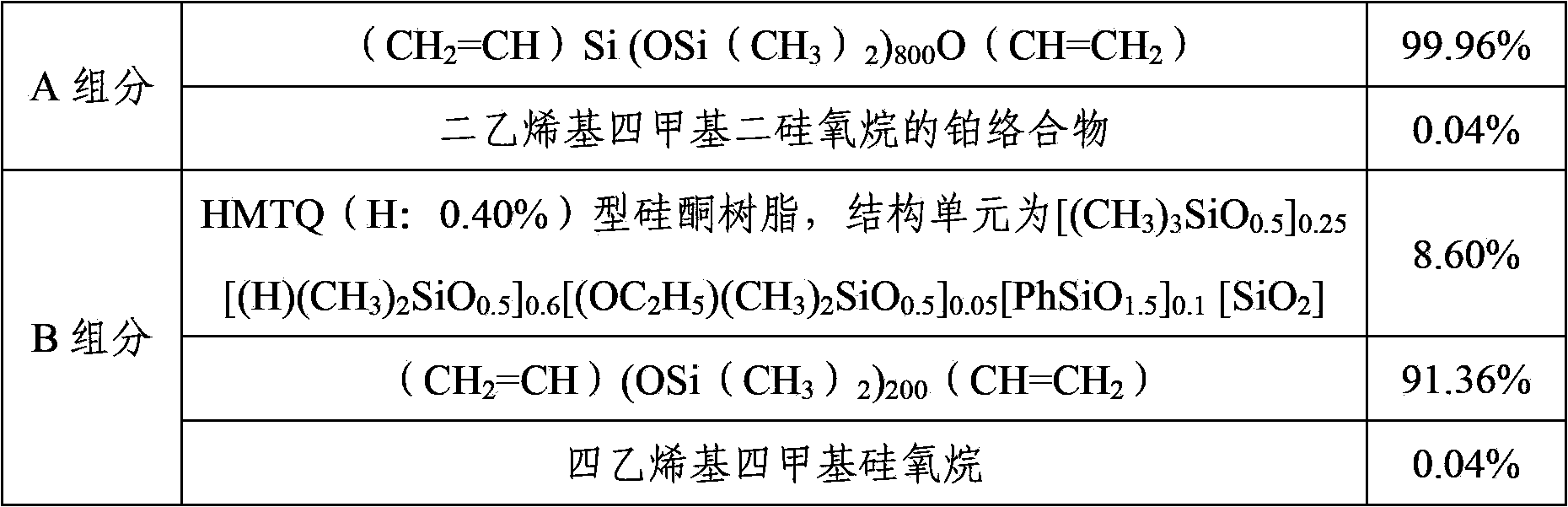

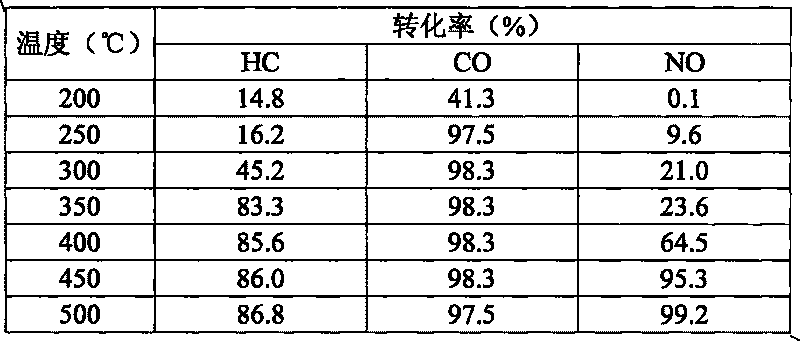

LED (light-emitting diode) organosilicon pouring sealant and application thereof

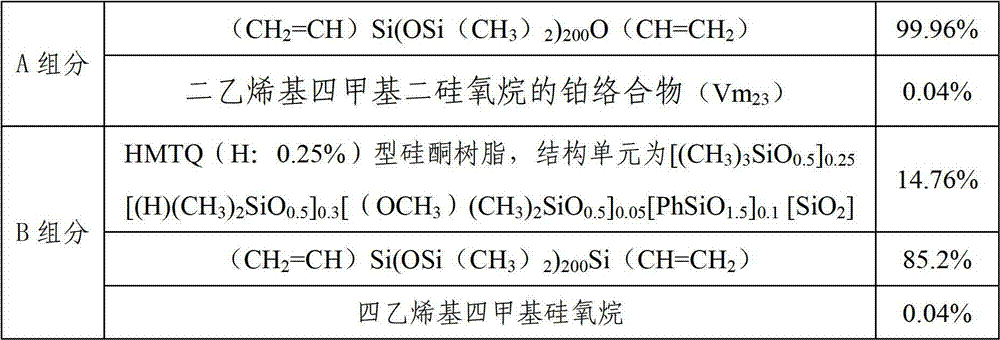

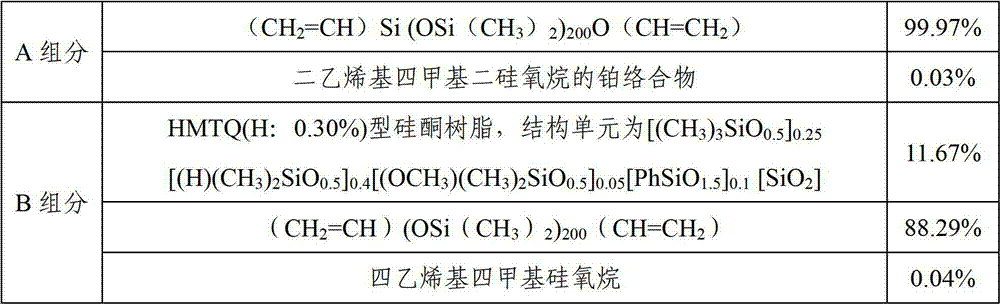

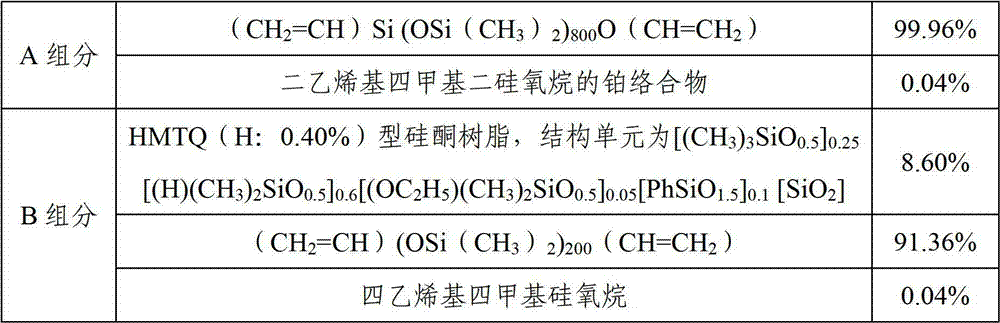

ActiveCN103666367AGood compatibilityHigh light transmittanceAdhesivesSemiconductor devicesOrganosiliconOrganic Silicon Compounds

The invention provides an LED (light-emitting diode) organosilicon pouring sealant. The LED organosilicon pouring sealant is composed of a component A and a component B, wherein the component A and the component B respectively comprise the following components that the component A is organopolysiloxane with a structural unit containing a -SiCH=CH2 group and a hydrogen silicide platinum family polysiloxane catalyst; the component B is organopolysiloxane with a structural unit containing a -SiCH=CH2 group, organopolysiloxane with a structural unit containing -SiH and at least one alkoxy, and alkynol or polyvinyl siloxane. When the pouring sealant provided by the invention is used for LED elements, the mixture is clear and transparent, and the compatibility is good; the pouring sealant has a good adhesive force on materials such as PPA (phenyl-propanolamine), PC (polycarbonate), zinc-plated aluminum and fluorescent powder in the LED elements after being cured at 50-60 DEG.C or room temperature, and the interlayer phenomenon is avoided; the organosilicon pouring sealant is high in transparency, cold and hot impact resistant, high temperature aging resistant and light aging resistant and has an excellent dielectric property.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

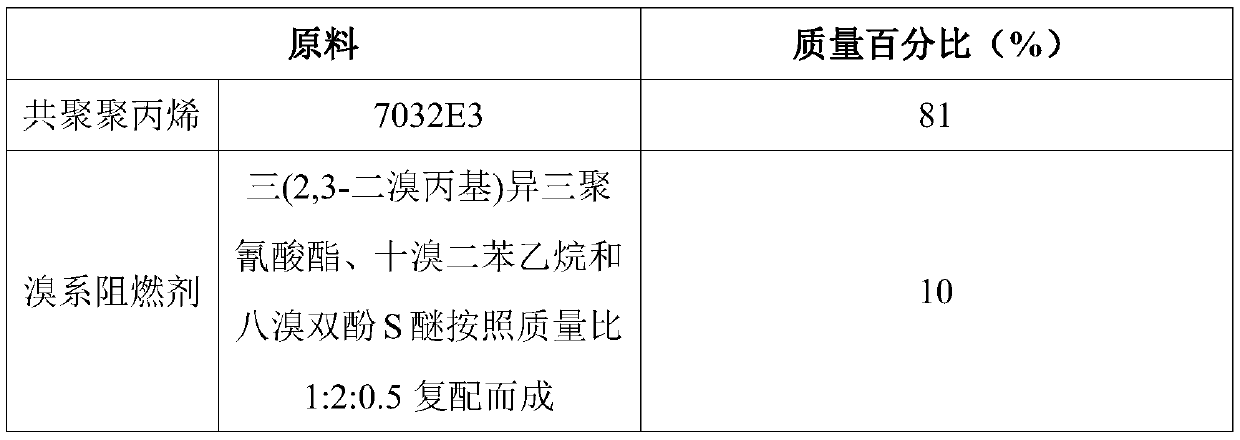

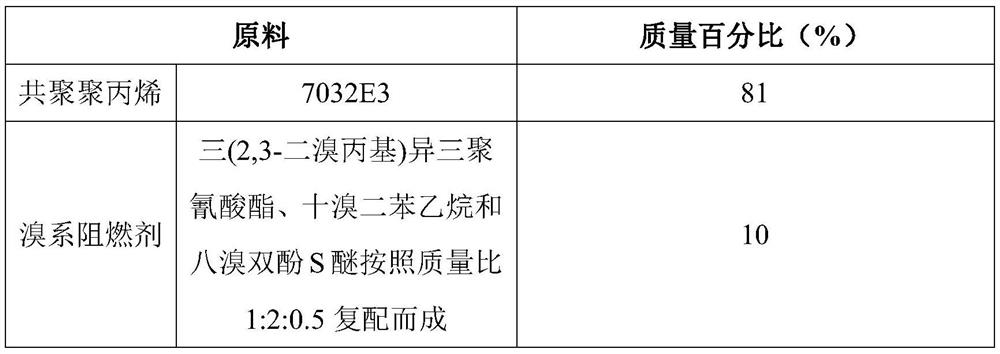

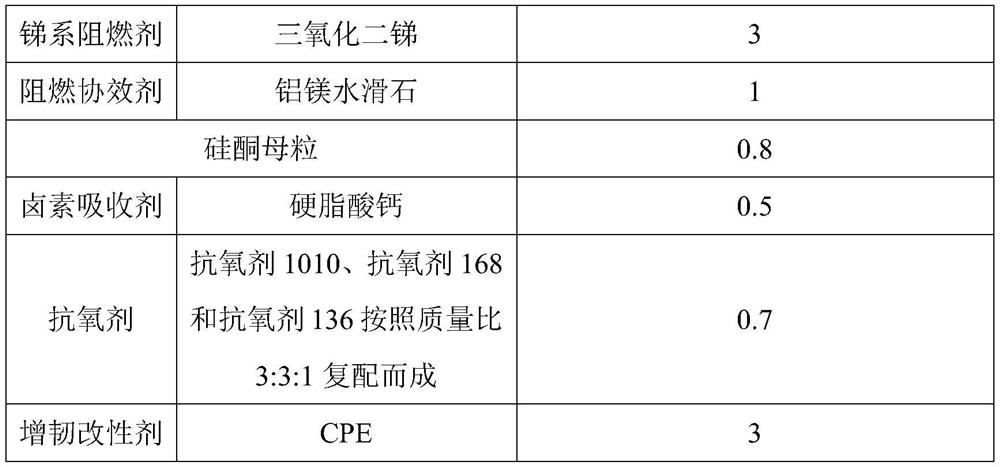

High-temperature ageing resistant and flame-resistant polypropylene material used for corrugated pipes and preparation method of polypropylene material

ActiveCN110079021AImprove flame retardant performanceGood high temperature aging resistanceAntioxidantPolypropylene

The invention discloses a high-temperature ageing resistant and flame-resistant polypropylene material used for corrugated pipes and a preparation method of the polypropylene material. The flame-resistant polypropylene material is prepared from co-polypropylene, a brominated flame retardant, an antimony flame retardant, a flame-retardant synergist, silicone master batch, a halogen absorber, an antioxidant and a toughening modifier. The preparation method of the polypropylene material is very simple and comprises steps as follows: firstly, all components are sufficiently and uniformly mixed inbatches, and then, extrusion, cooling, bracing and granulation are performed. The flame-resistant polypropylene material has a good flame retardant effect, has the flame-retardant grade up to grade UL92 V-2 and even grade V-0, has good high-temperature ageing resistance, can be baked at the temperature of 150 DEG C without embrittlement crack, is stable in processing performance, can realize continuous production, can allow laser carving and has smooth surfaces without granular sensation, the flame retardants are not separated, and the extruded corrugated pipes touch good and are not prone toburst by extrusion.

Owner:GUANGDONG JUSHI CHEM CO LTD

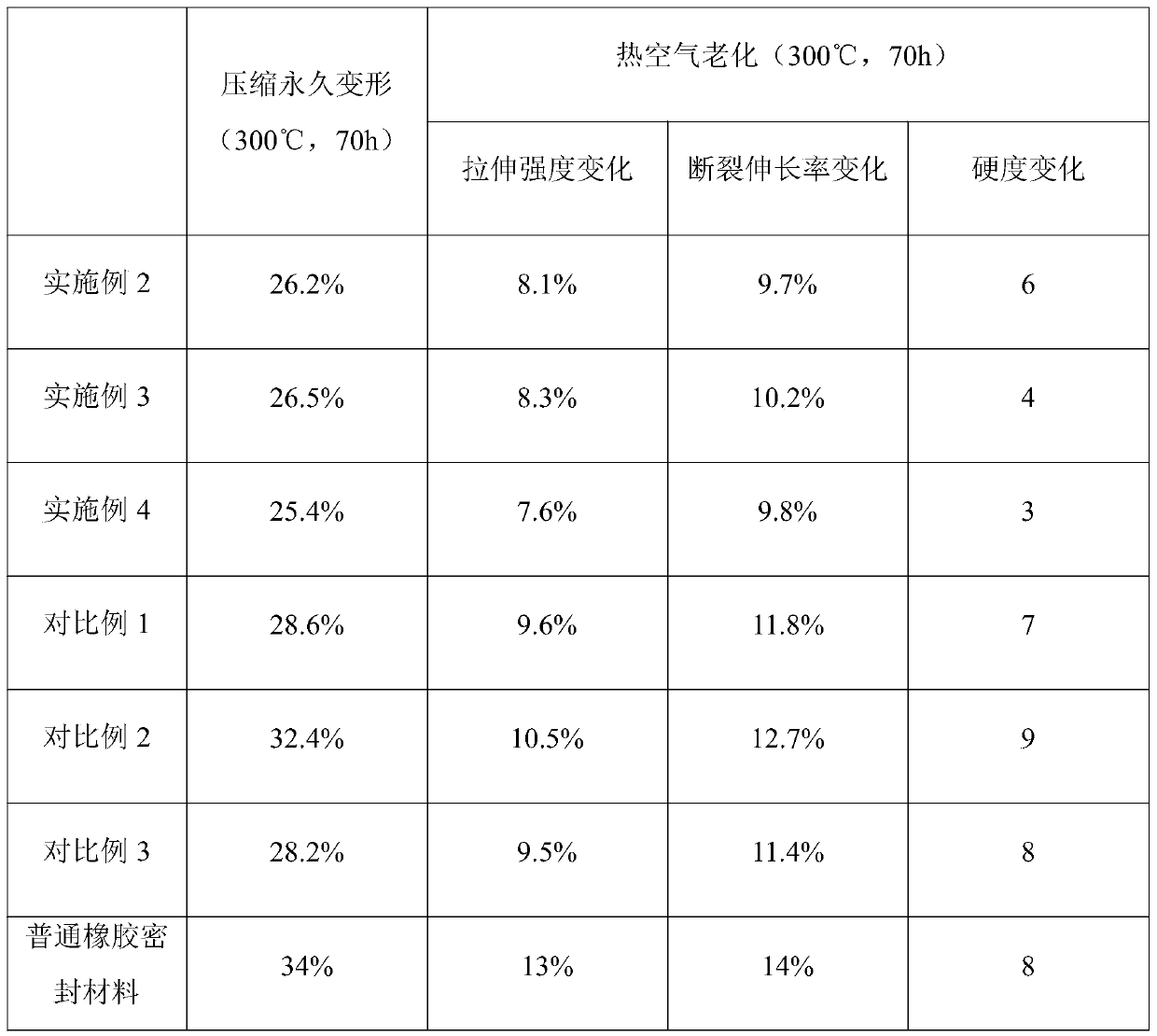

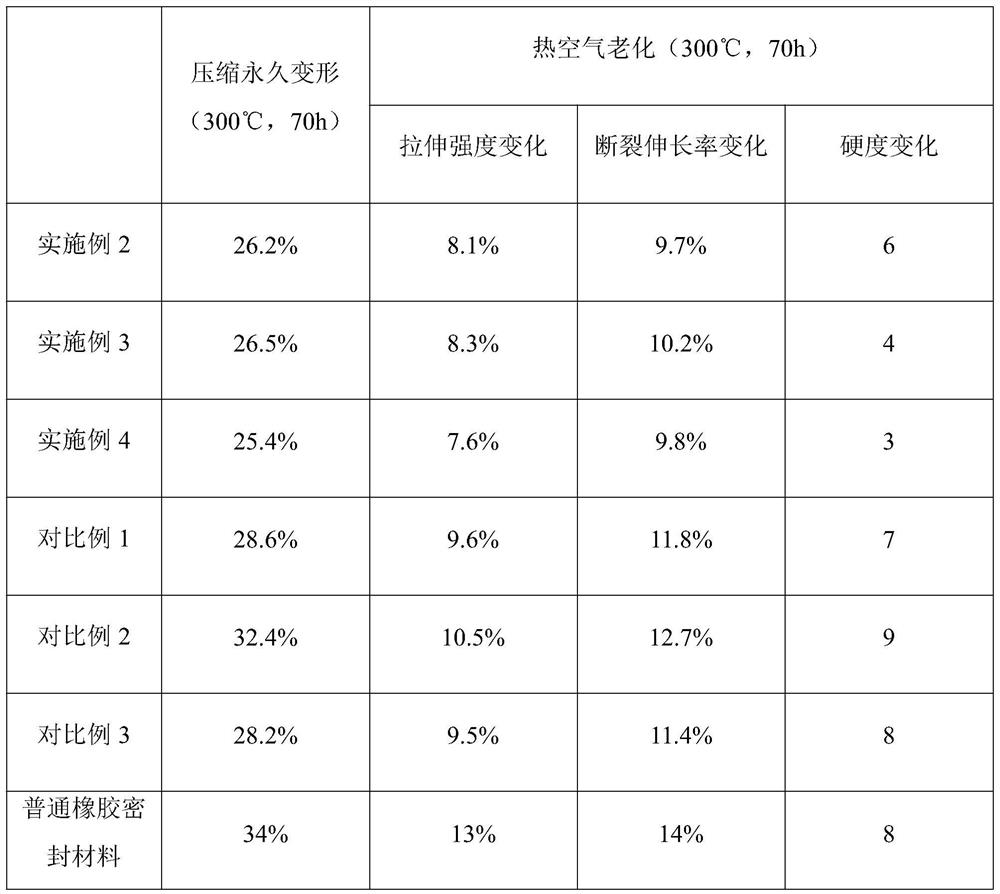

Anti-aging silicone rubber sealing material for high-speed rail sealing element and preparation method thereof

The invention discloses an anti-aging silicone rubber sealing material for a high-speed rail sealing element. The formula comprises the following raw materials in parts by weight: 60-70 parts of methyl vinyl silicone rubber, 25-30 parts of fluorosilicone rubber, 6-8 parts of hydroxyl-terminated polydimethylsiloxane, 0.7-0.9 part of a silane coupling agent, 0.12-0.15 part of toluene diisocyanate, 3-5 parts of white carbon black, 2-3 parts of fumed silica, 1.5-1.8 parts of zinc oxide, 2.5-4.5 parts of an anti-aging agent, 2-4 parts of a heat stabilizer and 2-4 parts of a cross-linking agent. Theanti-aging silicone rubber sealing material for the high-speed rail sealing element not only has good sealing performance, but also has excellent anti-aging performance, long service life, good oil resistance and solvent resistance, and good high-temperature aging resistance; in addition, the material also has the advantages of good elasticity, low compression set rate, high temperature resistance, good mechanical properties and the like.

Owner:XIANGYUSL PARTS

Modified phenol-formaldehyde resin adhesive and preparation method thereof

InactiveCN103911101AImprove adhesionIncrease polarityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveHexamethylenetetramine

The invention discloses a modified phenol-formaldehyde resin adhesive. The phenol-formaldehyde resin adhesive is composed of the following components by weight: 100-200 parts of a phenol-formaldehyde resin, 60-80 parts of polyvinylformal acetal, 20-40 parts of tetraethoxysilane, 3-6 parts of propyl gallate, 3-5 parts of hexamethylenetetramine, 2-4 parts of triethanolamine, 300-500 parts of ethyl acetate and 50-80 parts of anhydrous ethanol. Compared with a conventional phenol-formaldehyde resin adhesive, the modified phenol-formaldehyde resin adhesive provided by the invention has the following beneficial effects that (1) the phenol-formaldehyde resin contains a lot of hydroxymethyl and phenolic hydroxyl groups, so that the modified phenol-formaldehyde resin adhesive has large polarity, high bonding strength and good bonding property for metals and nonmetals; (2) the modified phenol-formaldehyde resin adhesive has relatively large rigidity and excellent heat-resistant property; and (3) the modified phenol-formaldehyde resin adhesive has relatively good high temperature ageing resistance and naturally ageing resistance in air.

Owner:WUJIANG KAIYING TRADE

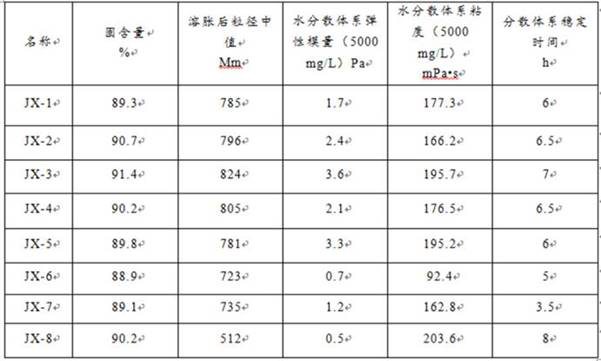

Temperature-resistant and salt-resistant multi-component copolymerization pre-crosslinked gel particle and preparation method and application thereof

The invention provides a temperature-resistant and salt-resistant multi-component copolymerization pre-crosslinked gel particle and a preparation method and application thereof, and belongs to the technical field of oil exploitation, transportation and chemical engineering. The pre-crosslinked gel particle is formed by copolymerization of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, is stable in copolymer structure, relatively good in high-temperature aging resistance, not easy to hydrolyze and good in compatibility with a polymer, greatly improves the viscosity of the system, andimproves the suspension performance of the pre-crosslinked gel particles in the system, and thus the oil displacement capacity of the system is higher, and the oil displacement efficiency is higher.

Owner:山东聚星石油科技有限公司

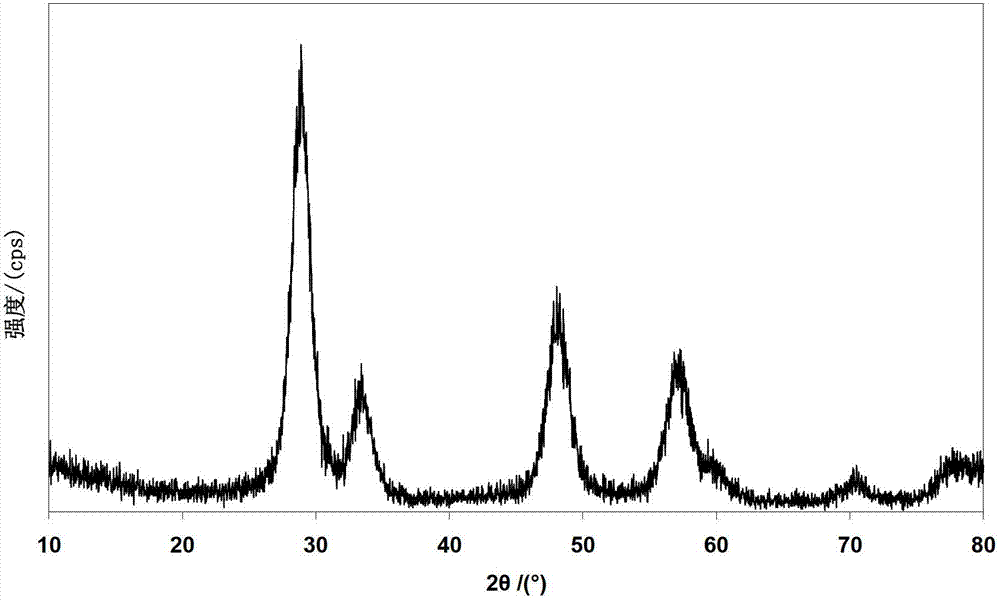

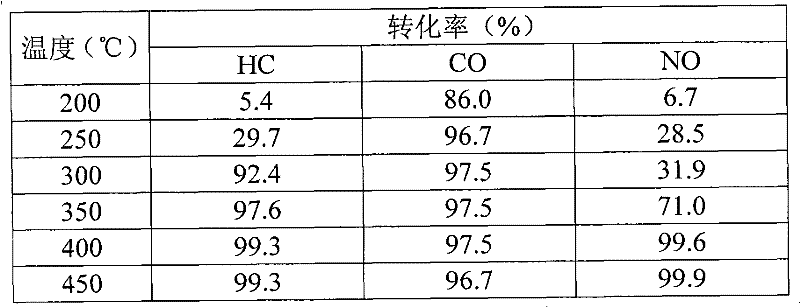

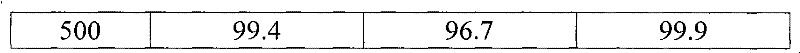

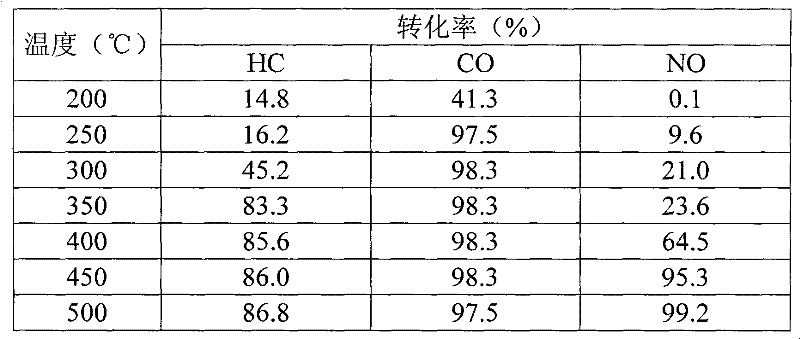

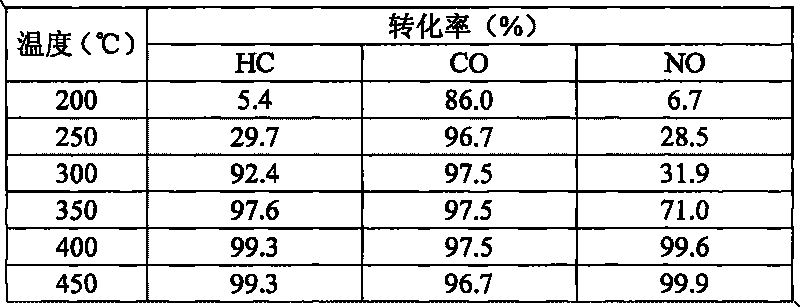

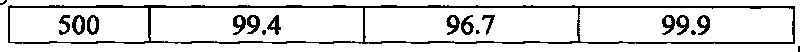

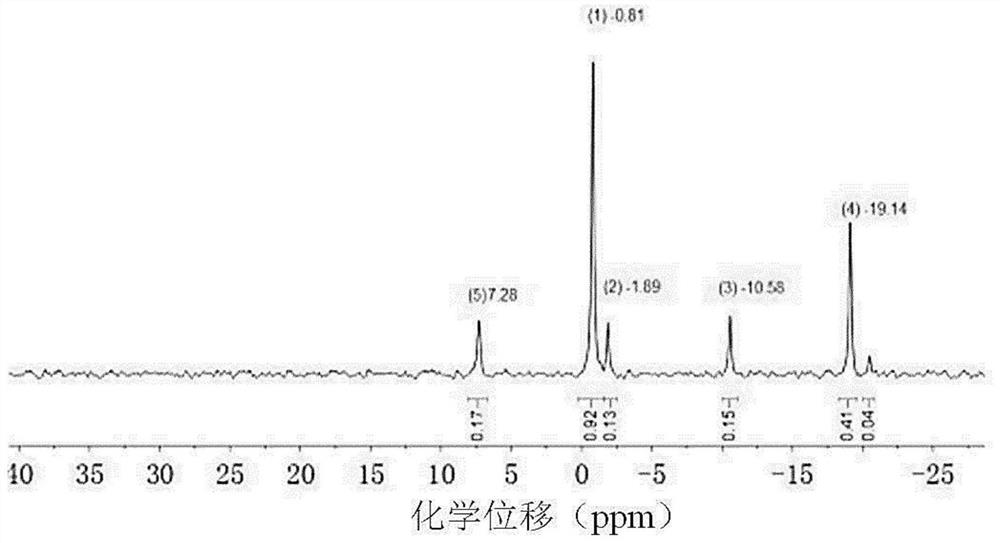

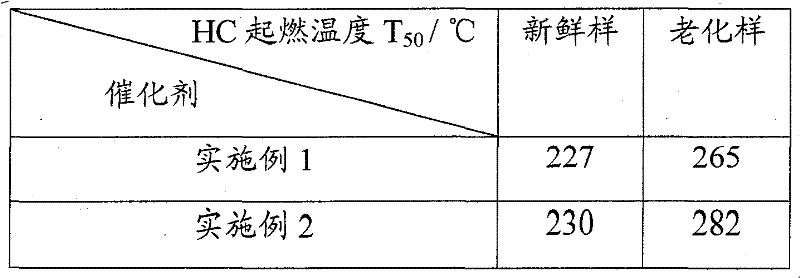

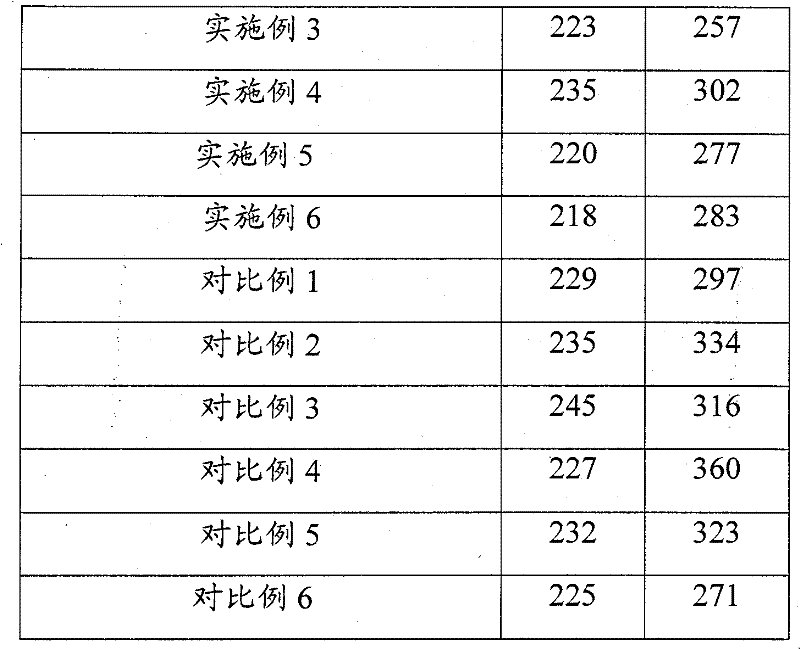

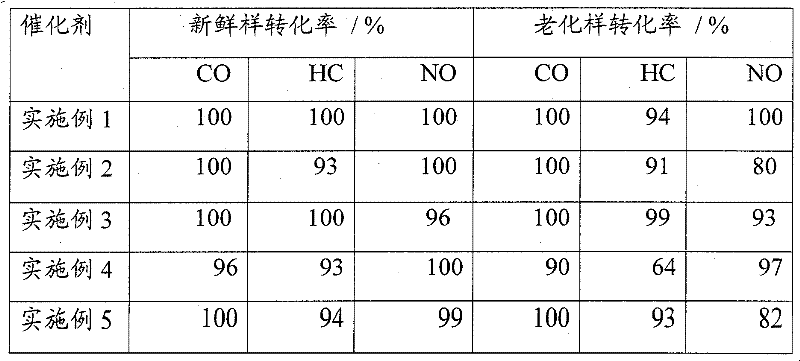

Cerium-zirconium-barium-copper oxide catalyst for purifying tail gas of lean-burn engine and preparation method thereof

InactiveCN101695661BReduce the catalytic oxidation temperatureGood high temperature aging resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBarium saltCatalytic oxidation

The invention discloses a three-way catalyst for improving the processing effect of hydrocarbons (HC) in the tail gas of a lean-burn engine and being capable of purifying carbon monoxide (CO) and nitrogen oxide (NO) and a preparation method thereof. The catalyst contains oxides of cerium, zirconium, barium and copper, wherein the mol ratio of the cerium to the zirconium to the barium to the copper is (2-15):(5-40):1:(0.5-1.5). Water-soluble cerate, zirconium salt and barium salt form an aqueous solution composition which is dropwise added into precipitator aqueous solution; solid substances are dried, ground and roasted at a temperature between 500 DEG C and 800 DEG C to obtain cerium-zirconium-barium oxide; the cerium-zirconium-barium oxide is impregnated into copper slat aqueous solution; and the mixture is dried and roasted at a temperature between 500 DEG C and 650 DEG C to obtain the catalyst. The invention can reduce the catalytic oxidation temperature of HC, has better high-temperature and ageing resistant performances and can be used for an exhaust system of the lean-burn engine to eliminate the pollution of HC, CO and NO on the environment.

Owner:SHANTOU UNIV

Environmentally-friendly super fiber leather for massage chair, and preparation method thereof

InactiveCN108824010AMeet environmental protection requirementsGood physical propertiesFurniture partsTextiles and paperPolymer scienceMassage

The invention provides an environmentally-friendly super fiber leather for a massage chair, and a preparation method thereof. The super fiber leather comprises a PU leather layer, a finishing layer applied to the upper surface of the PU leather layer, and an ultrafine fiber layer arranged under the lower surface of the PU leather layer; the PU leather layer comprises a base fabric and a surface layer applied to the surface of the base fabric; and the surface layer comprises, by weight, 90-110 parts of polyurethane resin, 80-100 parts of a solvent, 5-10 parts of a color paste and 0.1-0.5 part of a catalyst. The super fiber leather has the appearance effect of real leather, meets the requirements of environmental protection and the requirements of the massage chair for high physical properties, and also has a long service life.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

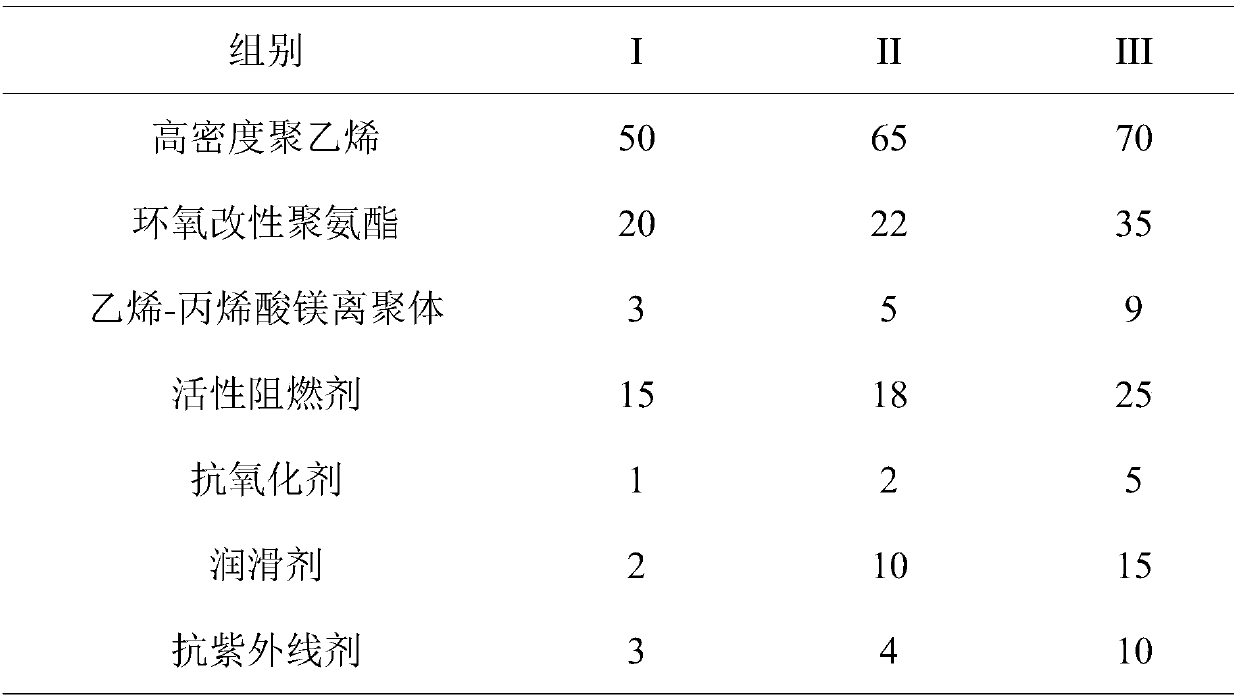

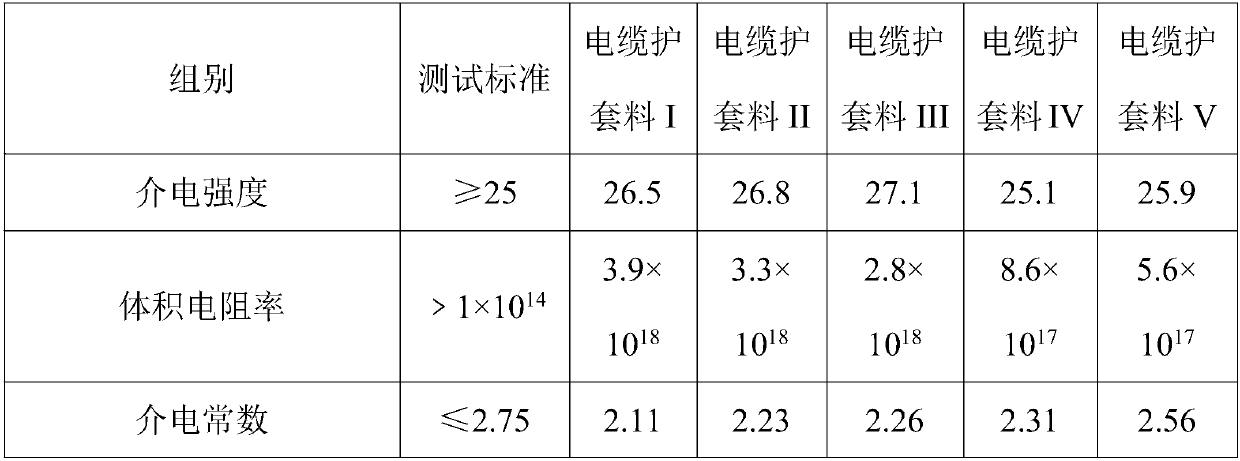

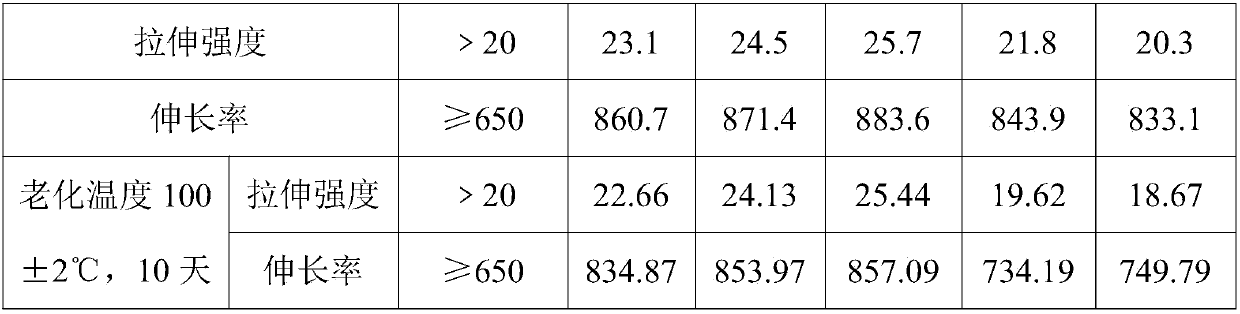

High-performance environment-friendly flame-retardant communication cable sheathing compound and preparation method thereof

InactiveCN108017827ALow dielectric lossHigh dielectric strengthPlastic/resin/waxes insulatorsHeavy metalsMagnesium

The invention discloses a high-performance environment-friendly flame-retardant communication cable sheathing compound and a preparation method thereof. The high-performance environment-friendly flame-retardant communication cable sheathing compound is prepared from high density polyethylene, epoxy modified polyurethane, an ethylene-magnesium acrylate ionomer, an active flame retardant, an antioxidant, a lubricating agent and an anti-ultraviolet agent. The high-performance environment-friendly flame-retardant communication cable sheathing compound provided by the invention has favorable fillerinclusiveness and crosslinkability by adopting the polyethylene as a main material and adding the epoxy modified polyurethane and the ethylene-magnesium acrylate ionomer for using cooperatively, so that the tensile strength and the elongation are improved; the active flame retardant is introduced to be modified through dimethyldichlorosilane so as to be uniformly and stably dispersed into a reaction system, so that a flame retardant effect of the high-performance environment-friendly flame-retardant communication cable sheathing compound provided by the invention is remarkably improved. The high-performance environment-friendly flame-retardant communication cable sheathing compound provided by the invention does not contain harmful heavy metal and halogenated hydrocarbon, has an excellentflame retardant effect, has electrical performance including low dielectric loss and high dielectric strength, has favorable processability and heat resistance, high strength, and high temperature aging resistance, and can satisfy a specific use environment; the preparation method is simple to operate with a high safety factor.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

Temperature-resistant and salt-resistant multi-component copolymerized pre-crosslinked gel particles and its preparation method and application

ActiveCN112279963BStable structureGood high temperature aging resistanceDrilling compositionChemical industryPolymer science

The invention proposes a temperature-resistant and salt-resistant multi-component copolymerized pre-crosslinked gel particle and its preparation method and application, which belong to the technical fields of petroleum exploitation, transportation and chemical industry. The pre-crosslinked gel particles provided by the present invention are formed by the copolymerization of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid. The copolymer has a stable structure, good high-temperature aging resistance, is not easy to hydrolyze, and has good contact with polymers. The compatibility of the system greatly increases the viscosity of the system, improves the suspension performance of the pre-crosslinked gel particles in the system, and makes the oil displacement capacity of the system stronger and the oil displacement efficiency higher.

Owner:山东聚星石油科技有限公司

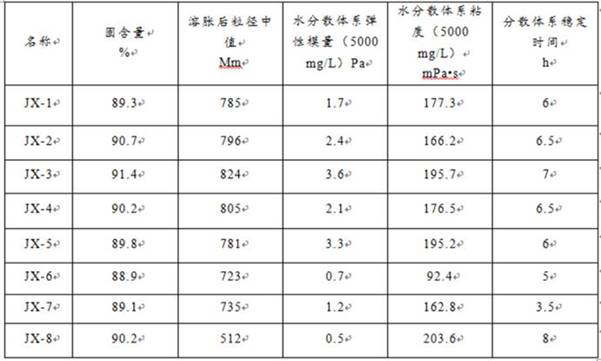

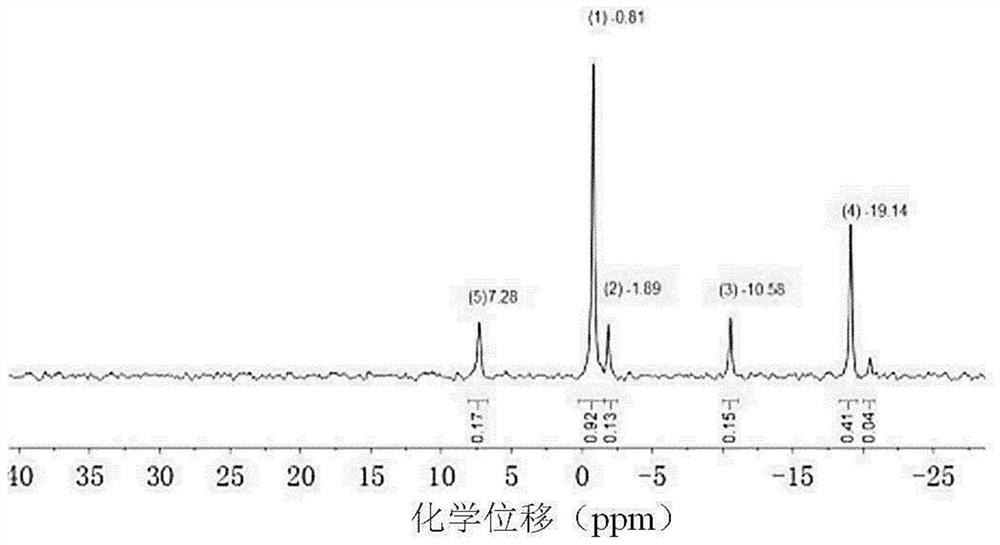

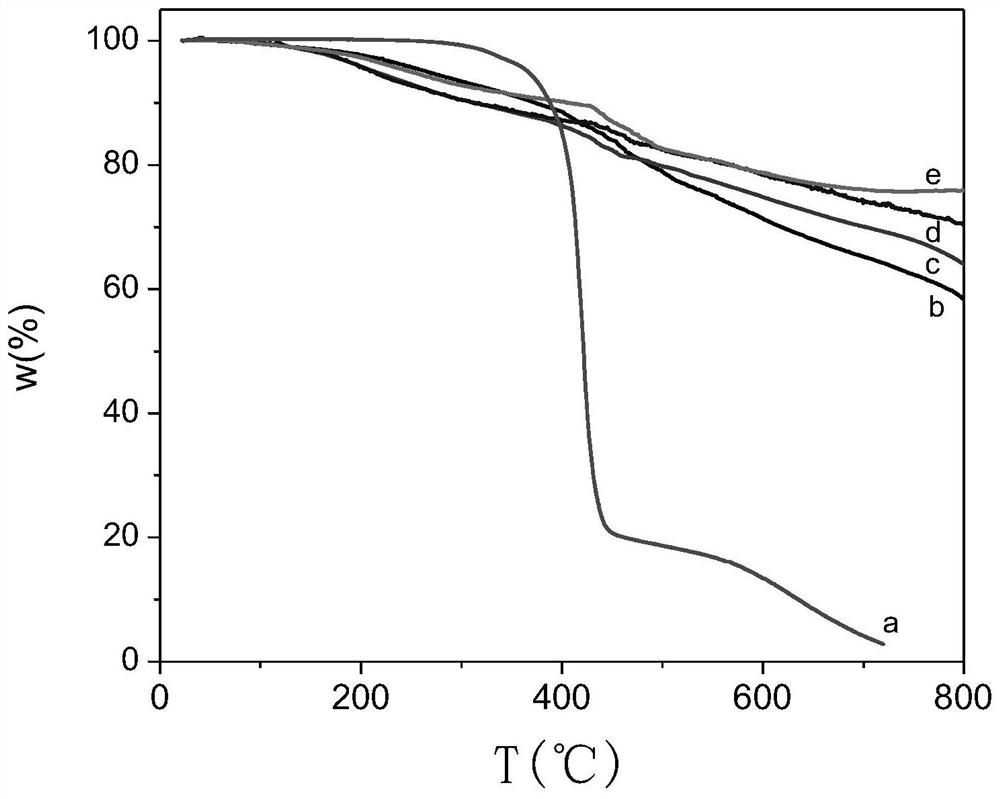

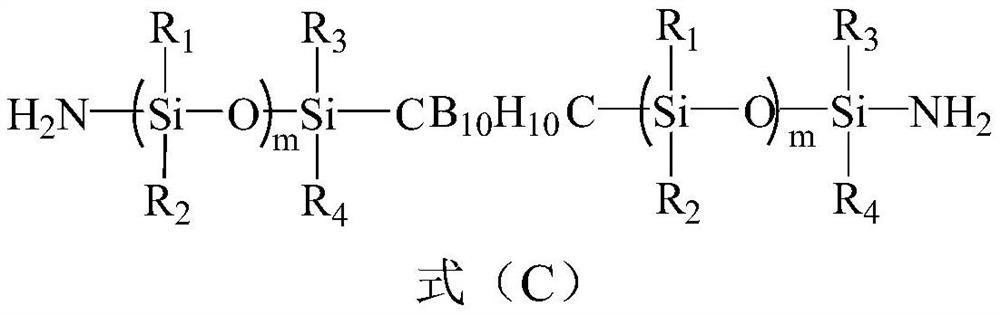

Amino curing agent, high-temperature-resistant epoxy resin containing curing agent and preparation method and application thereof

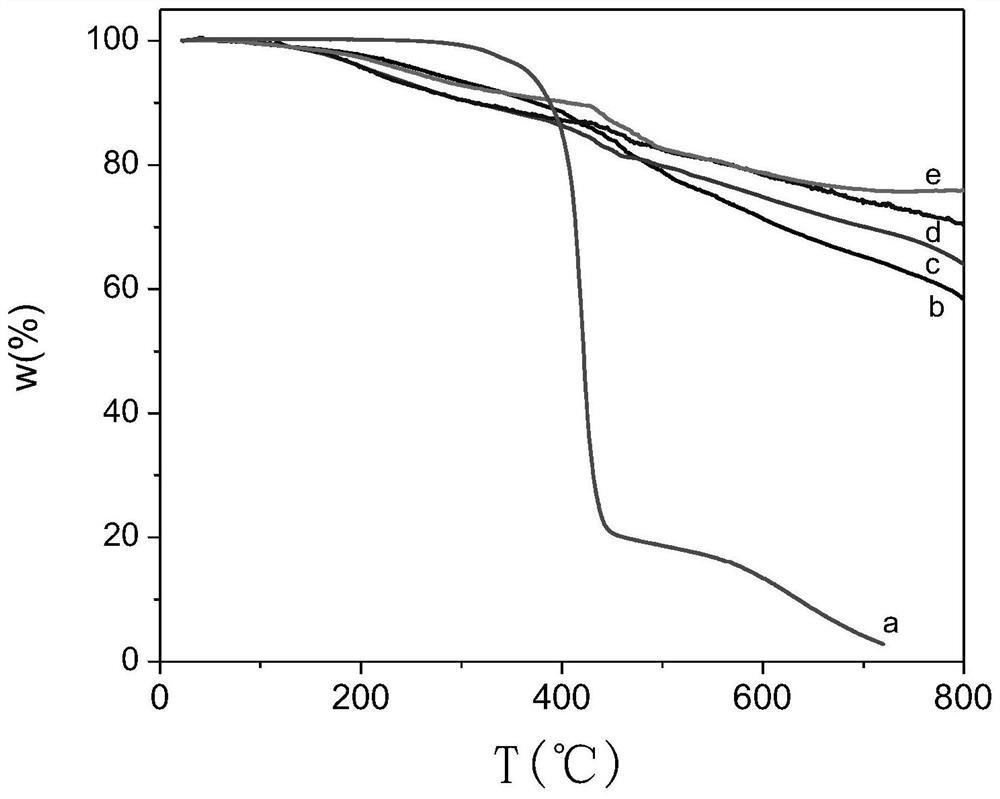

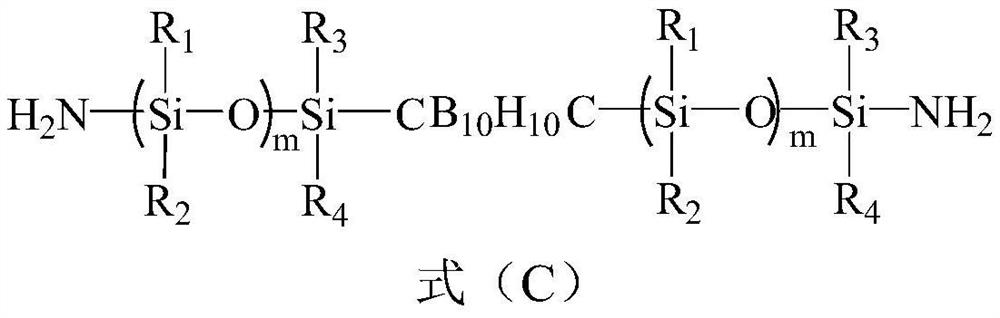

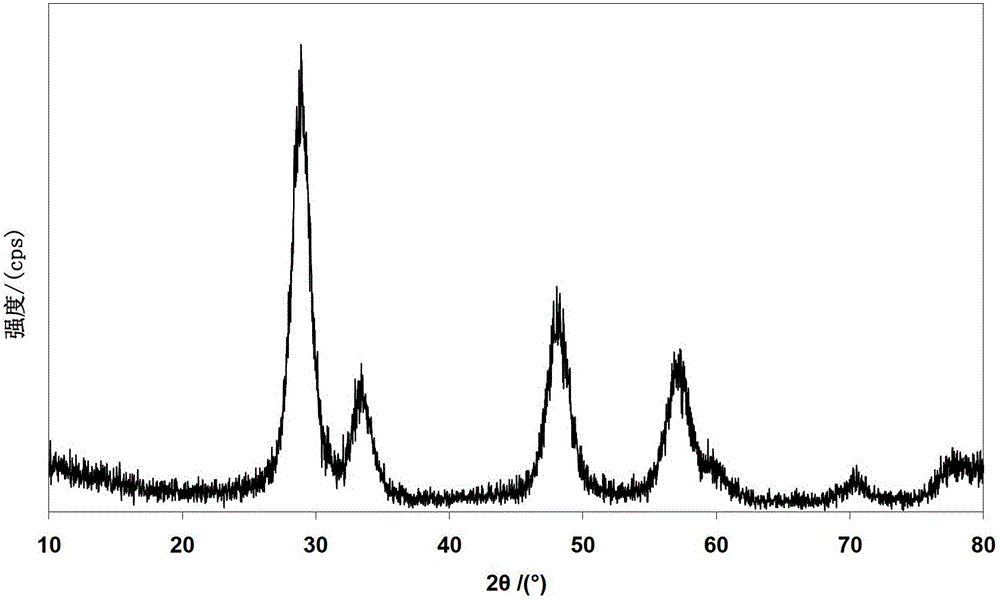

ActiveCN112011032AImprove high temperature resistanceGood bonding strength at room temperatureEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceAdhesive

The invention discloses an amino curing agent, high-temperature-resistant epoxy resin containing the curing agent and a preparation method and application thereof. The amino curing agent has a structure represented by the following formula (C). Raw materials for preparing the epoxy resin comprise an epoxy resin matrix and the amino curing agent, the amino curing agent comprises carborane and two amino groups, the two amino groups are end groups of the amino curing agent respectively, and the amino groups are directly connected with carborane groups, or the amino groups are connected with the carborane groups through aromatic hydrocarbon structures, silicon groups or siloxy groups respectively. The epoxy resin cured product is good in room-temperature bonding strength and can be used at thehigh temperature of 600 DEG C. The epoxy resin is suitable for being used as a resin matrix of a high-temperature-resistant adhesive and a high-temperature-resistant coating.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-temperature-resistant polyvinyl chloride pipe

The invention discloses a high-temperature-resistant polyvinyl chloride pipe, which is prepared from the following raw materials in parts by weight: 40-50 parts of polyvinyl chloride, 15-24 parts of methyl vinyl silicone rubber, 1-2 parts of 1, 3-bis (tert-butyl peroxy isopropyl) benzene, 0.2-0.8 part of N-cyclohexyl-2-benzothiazolesulfenamide, 1-2 parts of zinc oxide, 40-50 parts of a filling reinforcing agent, 1-3 parts of magnesium oxide, 1-2 parts of carboxymethyl cellulose, 1-3 parts of an anti-aging agent, 1-2 parts of poly-metaphosphoric acid and 3-6 parts of a plasticizer. The high-temperature-resistant polyvinyl chloride pipe provided by the invention has high temperature aging resistance, thus being used for a long time at the temperature of 230 DEG C and better maintaining the physical properties at the temperature of 280 DEG C; the high-temperature-resistant polyvinyl chloride pipe has ultra-low compression permanent deformation, thus achieving the effect of effective sealing in a using process.

Owner:ANHUI LANTONG TECH CO LTD

Cerium-zirconium-barium-copper oxide catalyst for purifying tail gas of lean-burn engine and preparation method thereof

InactiveCN101695661AReduce the catalytic oxidation temperatureGood high temperature aging resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBarium saltCatalytic oxidation

The invention discloses a three-way catalyst for improving the processing effect of hydrocarbons (HC) in the tail gas of a lean-burn engine and being capable of purifying carbon monoxide (CO) and nitrogen oxide (NO) and a preparation method thereof. The catalyst contains oxides of cerium, zirconium, barium and copper, wherein the mol ratio of the cerium to the zirconium to the barium to the copper is (2-15):(5-40):1:(0.5-1.5). Water-soluble cerate, zirconium salt and barium salt form an aqueous solution composition which is dropwise added into precipitator aqueous solution; solid substances are dried, ground and roasted at a temperature between 500 DEG C and 800 DEG C to obtain cerium-zirconium-barium oxide; the cerium-zirconium-barium oxide is impregnated into copper slat aqueous solution; and the mixture is dried and roasted at a temperature between 500 DEG C and 650 DEG C to obtain the catalyst. The invention can reduce the catalytic oxidation temperature of HC, has better high-temperature and ageing resistant performances and can be used for an exhaust system of the lean-burn engine to eliminate the pollution of HC, CO and NO on the environment.

Owner:SHANTOU UNIV

An amine-based curing agent, a high-temperature-resistant epoxy resin containing the curing agent, its preparation method and application

ActiveCN112011032BImprove high temperature resistanceGood bonding strength at room temperatureEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceAdhesive

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-sealing silicone rubber material

The invention provides a high-sealing silicone rubber material which comprises nano kaolin, a water blocking agent, a damping agent, low phenyl silicone rubber, nano ceramic powder, high-temperature-resistant resin, a fire retardant, zinc oxide, a heat stabilizer, a nano anti-wear agent, fluorinated silicone rubber and a cross-linking agent. Concretely, the silicone rubber is prepared from the following components in parts by weight: 3 to 5 parts of nano kaolin, 1 to 2 parts of water blocking agent, 1 to 2 parts of damping agent, 60 to 75 parts of low phenyl silicone rubber, 5 to 7 parts of nano ceramic powder, 10 to 15 parts of high-temperature-resistant resin, 2 to 3 parts of fire retardant, 1 to 2 parts of zinc oxide, 1.3 to 1.7 parts of heat stabilizer, 2 to 3 parts of nano anti-wear agent, 20 to 30 parts of fluorinated silicone rubber and 2 to 4 parts of cross-linking agent. The high-sealing silicone rubber material has the advantages of favorable sealing property, excellent aging resistance, long service life, favorable oil resistance, favorable solvent resistance and favorable high-temperature aging resistance. In addition, the material also has the advantages of high elasticity, low compression set rate, high temperature resistance, high mechanical properties and the like.

Owner:惠州市兴华源家居用品有限公司

Aluminum-cerium-zirconium composite oxide catalyst material and preparation method thereof

ActiveCN102824904BEnhanced interactionGuaranteed uniformityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumRare earth

The invention aims to disclose a composite aluminium, cerium and zirconium oxide catalytic material and a method for producing the same. The composite aluminium, cerium and zirconium oxide catalytic material is a composite oxide which consists of 15-30% of cerium oxide, 5-20% of zirconium oxide, 50-75% of aluminium oxide and 0-5% of other rear earth oxides expect cerium by weight. Compared with the prior art, the aluminium oxide is subjected to surface treatment, on one hand, the interaction of the aluminium oxide and the cerium and zirconium-base composite oxides is enhanced; and on the other hand, the uniformity of the aluminium oxide and the cerium and zirconium-base composite oxides is fully ensured; through the modification of a structural directing agent and a dispersing agent, the pore diameter and pore volume of the composite aluminium, cerium and zirconium oxide catalytic material are further improved, and good temperature resistance and aging resistance are obtained; and moreover, the composite aluminium, cerium and zirconium oxide catalytic material has the advantages of high oxygen storage capability and high oxygen storage and release velocities, so the purpose of the invention is realized.

Owner:上海华明高纳稀土新材料有限公司

LED (light-emitting diode) organosilicon pouring sealant and application thereof

ActiveCN103666367BGood compatibilityImprove liquidityAdhesivesSemiconductor devicesPolymer sciencePolycarbonate

The invention provides an LED (light-emitting diode) organosilicon pouring sealant. The LED organosilicon pouring sealant is composed of a component A and a component B, wherein the component A and the component B respectively comprise the following components that the component A is organopolysiloxane with a structural unit containing a -SiCH=CH2 group and a hydrogen silicide platinum family polysiloxane catalyst; the component B is organopolysiloxane with a structural unit containing a -SiCH=CH2 group, organopolysiloxane with a structural unit containing -SiH and at least one alkoxy, and alkynol or polyvinyl siloxane. When the pouring sealant provided by the invention is used for LED elements, the mixture is clear and transparent, and the compatibility is good; the pouring sealant has a good adhesive force on materials such as PPA (phenyl-propanolamine), PC (polycarbonate), zinc-plated aluminum and fluorescent powder in the LED elements after being cured at 50-60 DEG.C or room temperature, and the interlayer phenomenon is avoided; the organosilicon pouring sealant is high in transparency, cold and hot impact resistant, high temperature aging resistant and light aging resistant and has an excellent dielectric property.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

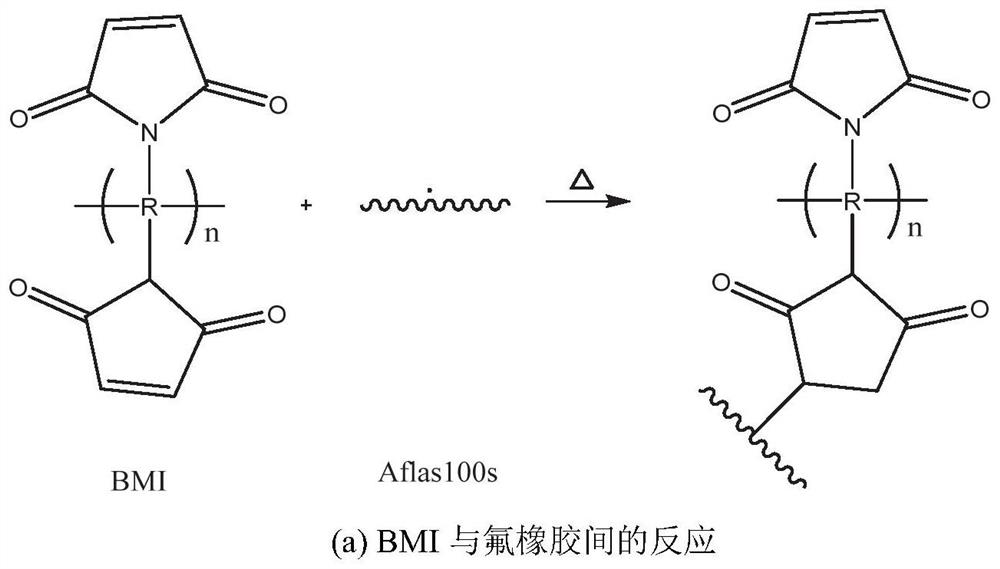

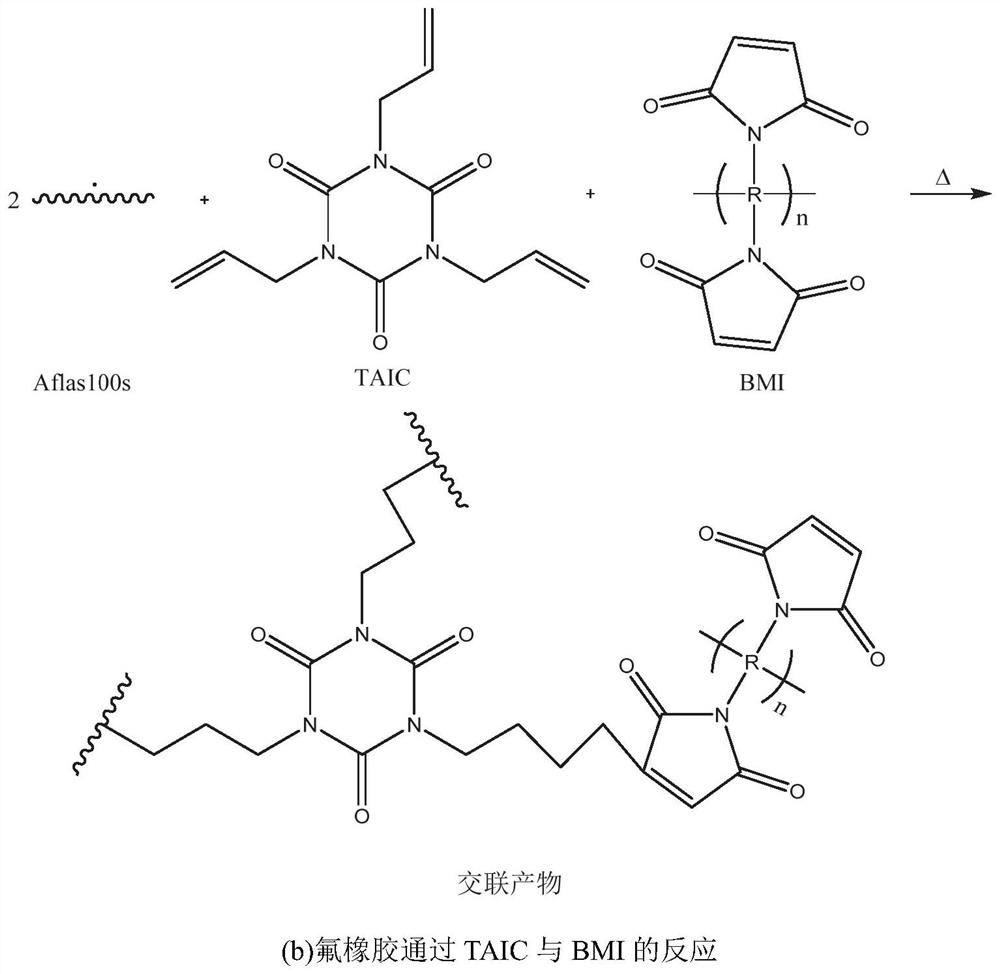

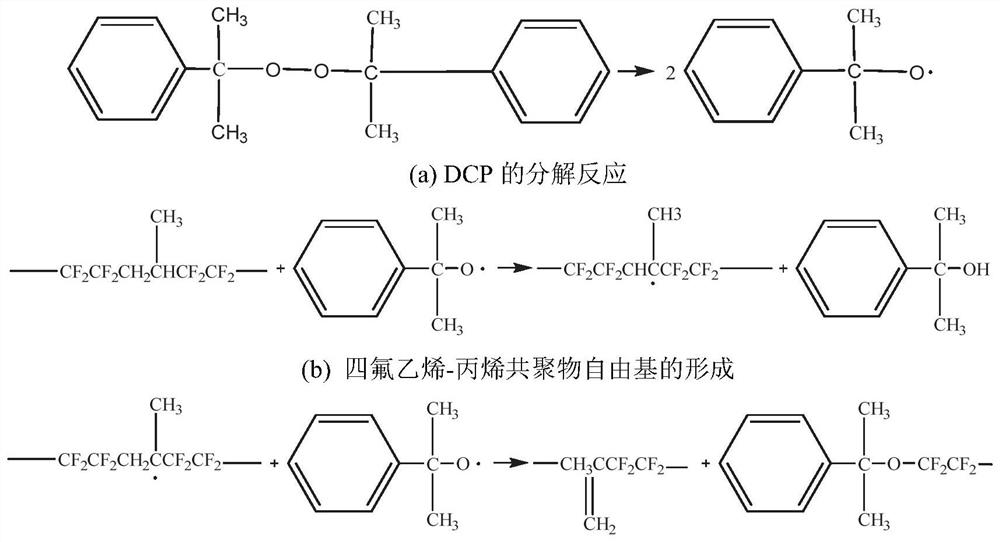

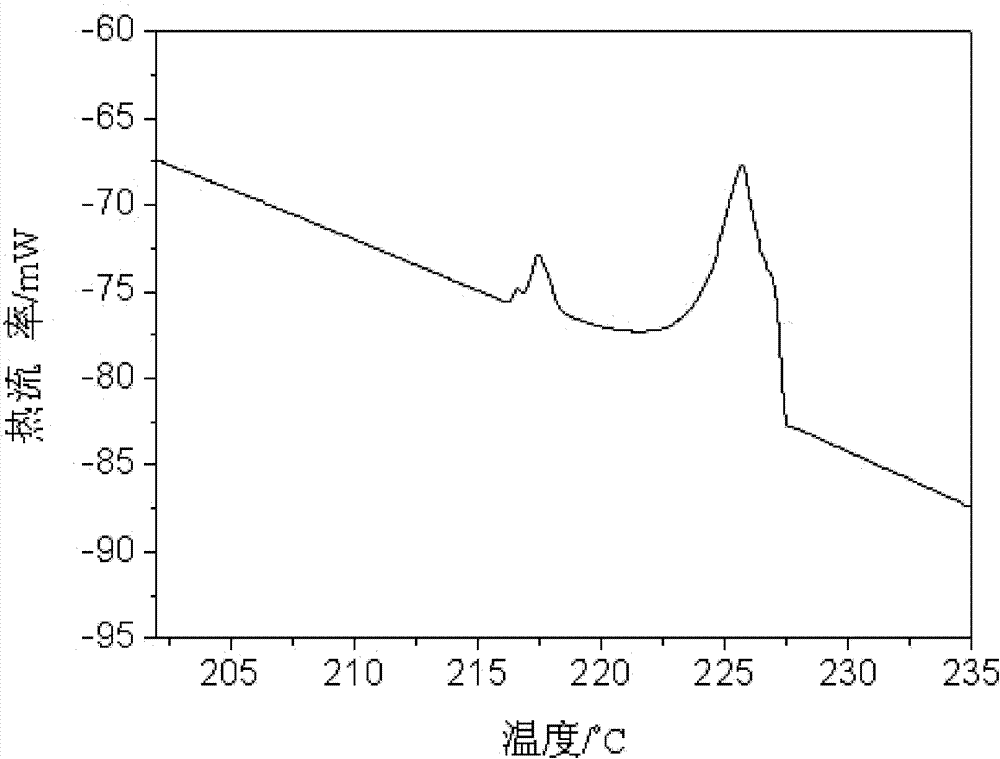

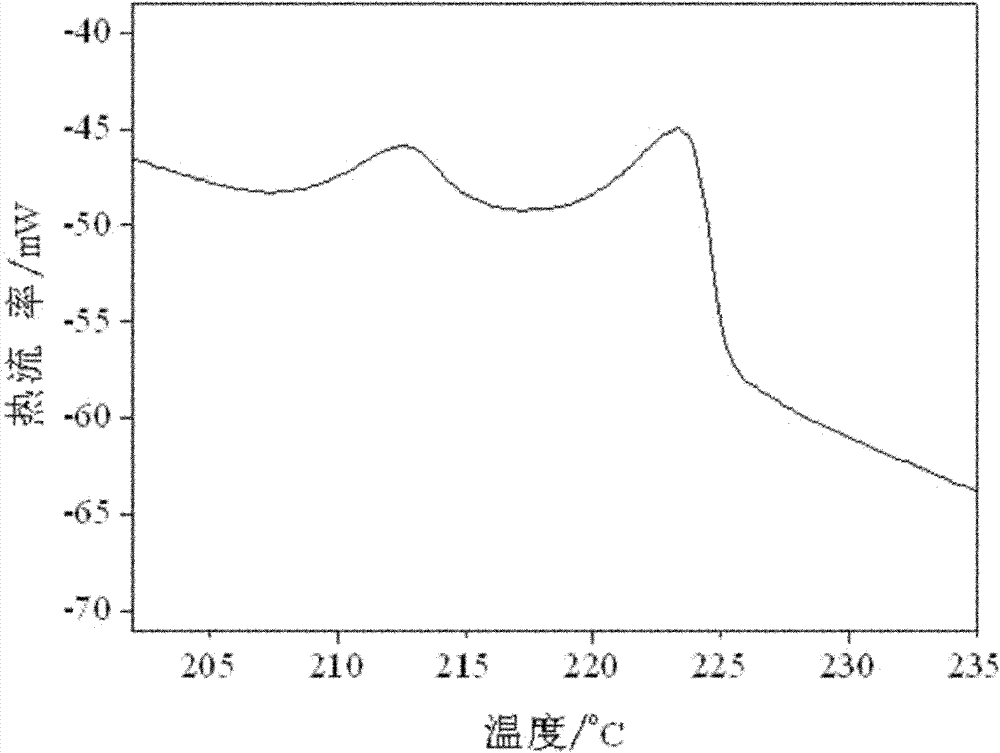

Viscoelastic sandwich material, large-damping sandwich composite material and preparation method and application thereof

The invention relates to the technical field of high polymer materials, in particular to a viscoelastic sandwich material, a large-damping sandwich composite material and a preparation method and application thereof. According to the large-damping sandwich composite material, a carbon fiber prepreg serves as a neutral layer to be embedded into a bismaleimide resin matrix composite material, the surface of the carbon fiber prepreg is provided with viscoelastic sandwich materials with different thicknesses, and the viscoelastic sandwich materials comprise the following components in parts by mass: 90-110 parts of tetrafluoroethylene-propylene rubber; 4-6 parts of a cross-linking agent TAIC; 4-6 parts of a vulcanizing aid HVA-2; 1-1.5 parts of a vulcanizing agent BIBP; 30-50 parts of ZDMA; 1-2 parts of an activator NASA; and 10-20 parts of short fibers. The large-damping sandwich composite material has good high-temperature resistance and high interface shear strength, meanwhile, the fracture surface of the large-damping sandwich composite material occurs in the sandwich material of the neutral layer, and the composite structure has excellent mechanical properties; and the damping performance of the composite material is greatly improved through embedding of the sandwich material, and the material has a wide application prospect in aerospace.

Owner:WEIFANG UNIV OF SCI & TECH

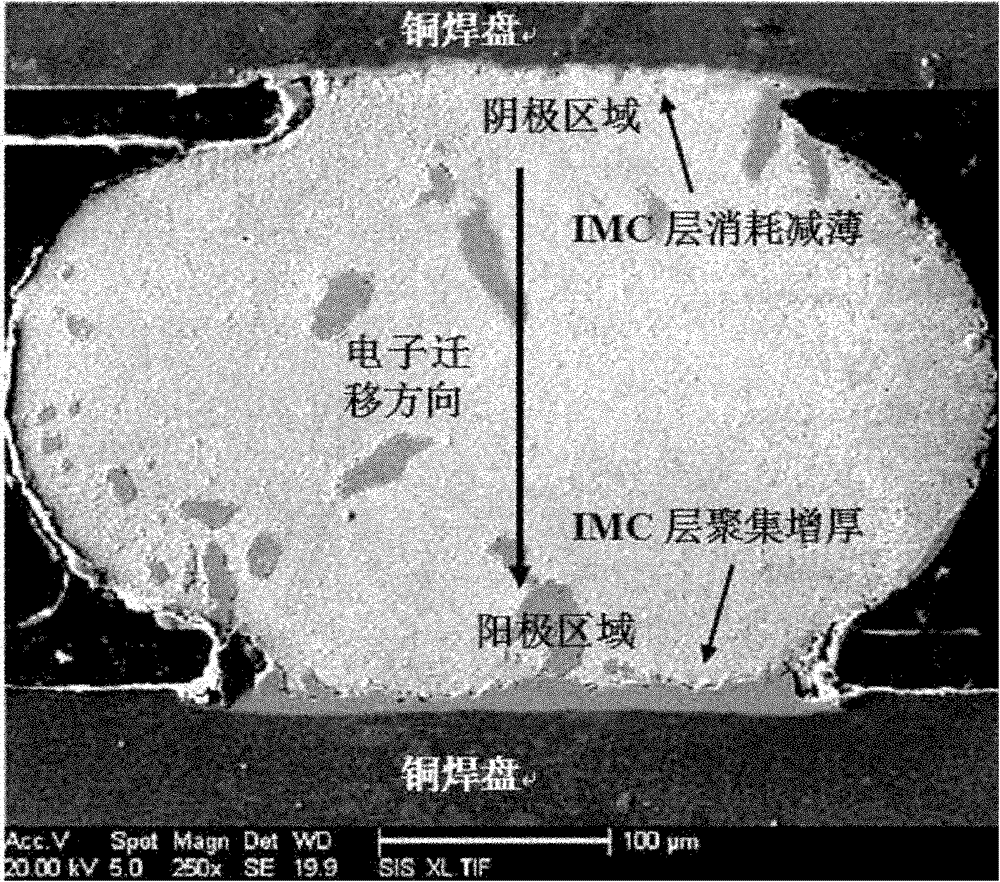

Low-cost anti-aging brazing filler material used for electronic packaging and preparation method thereof

InactiveCN102172805BLow silver contentHigh melting pointWelding/cutting media/materialsSoldering mediaFiller metalElectron

Owner:HARBIN UNIV OF SCI & TECH

A kind of anti-aging silicone rubber sealing material for high-speed rail seal and preparation method thereof

The invention discloses an aging-resistant silicone rubber sealing material for high-speed rail sealing parts. 6-8 parts of oxane, 0.7-0.9 parts of silane coupling agent, 0.12-0.15 parts of tolyl diisocyanate, 3-5 parts of silica, 2-3 parts of fumed silica, 1.5-1.8 parts of zinc oxide , 2.5 to 4.5 parts of anti-aging agent, 2 to 4 parts of heat stabilizer, and 2 to 4 parts of crosslinking agent. The aging-resistant silicone rubber sealing material for high-speed rail seals of the present invention not only has good sealing performance, but also has excellent aging resistance, long service life, good oil and solvent resistance, and high temperature aging resistance; Good elasticity, low compression set, high temperature resistance and good mechanical properties.

Owner:XIANGYUSL PARTS

Automobile tail gas cleaning catalyst and its preparation method

ActiveCN101362091BImprove anti-poisoning performanceLow costDispersed particle separationCatalyst activation/preparationSlurryPt element

The invention provides a catalyst used for purifying motor vehicle exhaust, and a preparation method thereof. The catalyst comprises a carrier with one coating or a plurality of coatings; and each coating contains alumina carrying silver and an oxygen storage material carrying platinum / palladium, wherein the silver is impregnated to be carried on the active alumina by a mixed solution of soluble silver salt and citric acid, and the platinum and the palladium are respectively impregnated to be carried on the oxygen storage material by the salt solutions thereof, so that the platinum and the palladium are not carried on the same oxygen storage material, the oxygen storage material is a mixture of cerium oxide and zirconia, the cerium oxide or ceria-zirconia solid solution, the Ag and Pt / Pd are separately carried on different oxide carriers. The preparation method comprises the following steps: (1) preparing the alumina carrying the silver, the oxygen storage material carrying the platinum and the oxygen storage material carrying the palladium; (2) preparing coating slurry; and (3) coating the coating slurry on the catalyst carrier. The catalyst provided by the invention for purifying the motor vehicle exhaust has low cost, good combustion activity and good resistance to aging.

Owner:BYD CO LTD

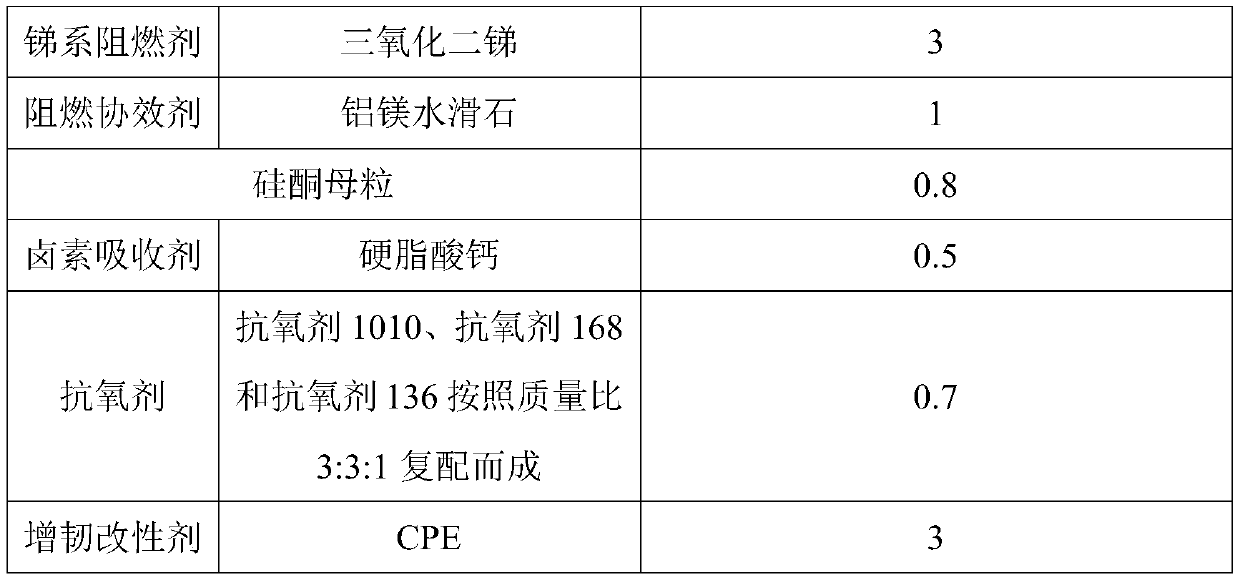

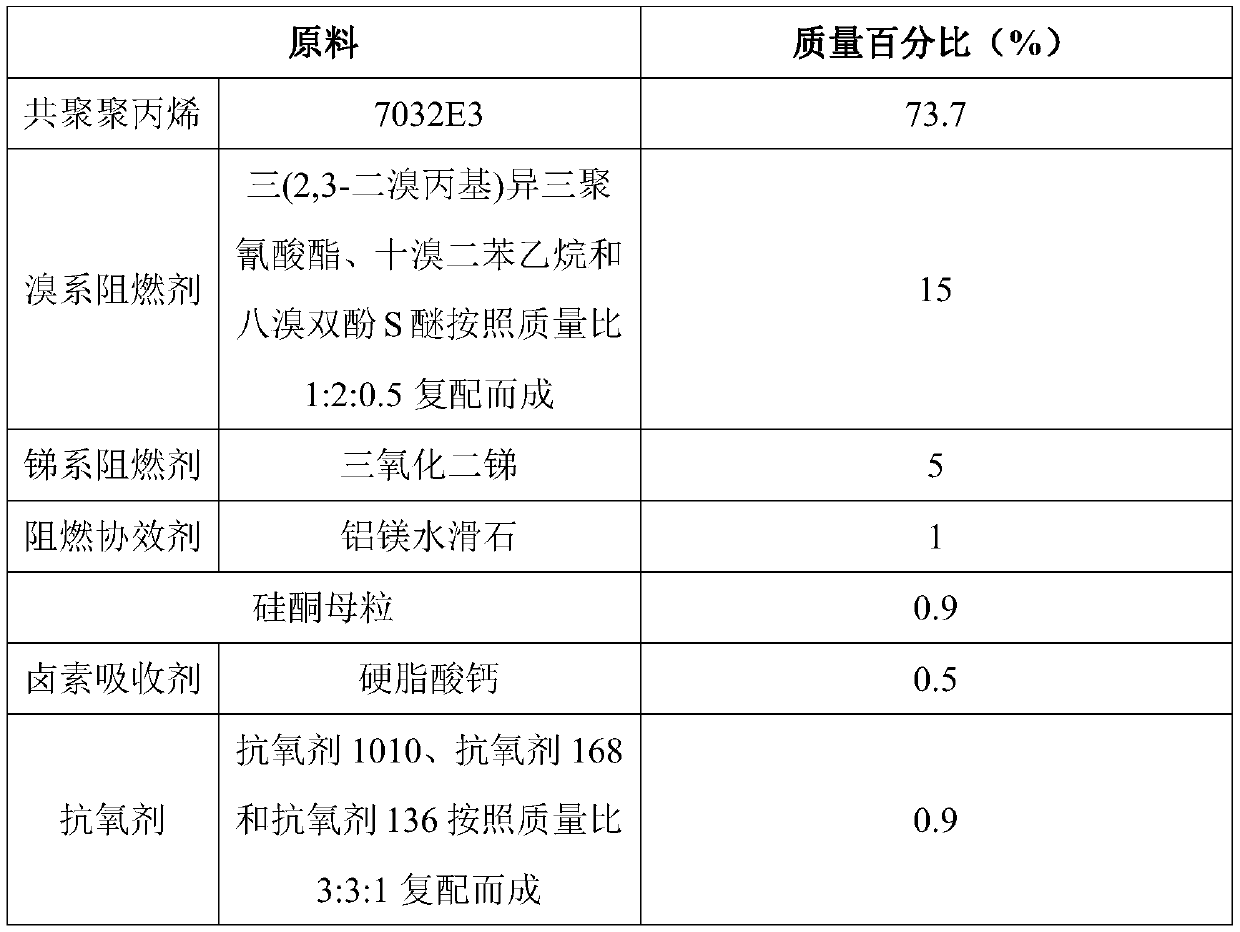

A high-temperature aging-resistant flame-retardant polypropylene material for bellows and its preparation method

ActiveCN110079021BImprove flame retardant performanceGood high temperature aging resistanceMasterbatchAntioxidant

The invention discloses a high-temperature aging-resistant flame-retardant polypropylene material for bellows and a preparation method thereof. The flame-retardant polypropylene material is composed of copolymerized polypropylene, a brominated flame retardant, an antimony-based flame It is composed of effect agent, silicone masterbatch, halogen absorber, antioxidant and toughening modifier. The preparation method is very simple. First, the components are fully mixed in batches, and then extrusion, cooling, drawing, Finely dice. The flame-retardant polypropylene material of the present invention has a good flame-retardant effect, and the flame-retardant grade can reach UL94 V-2 level, or even V-0 level, has good high-temperature aging resistance, and can be baked at 150°C for 360 hours without brittle cracking , Stable processing performance, continuous production, laser engraving, smooth surface without graininess, no precipitation of flame retardant, good hand feeling of extruded bellows, not easy to squeeze and burst.

Owner:GUANGDONG JUSHI CHEM CO LTD

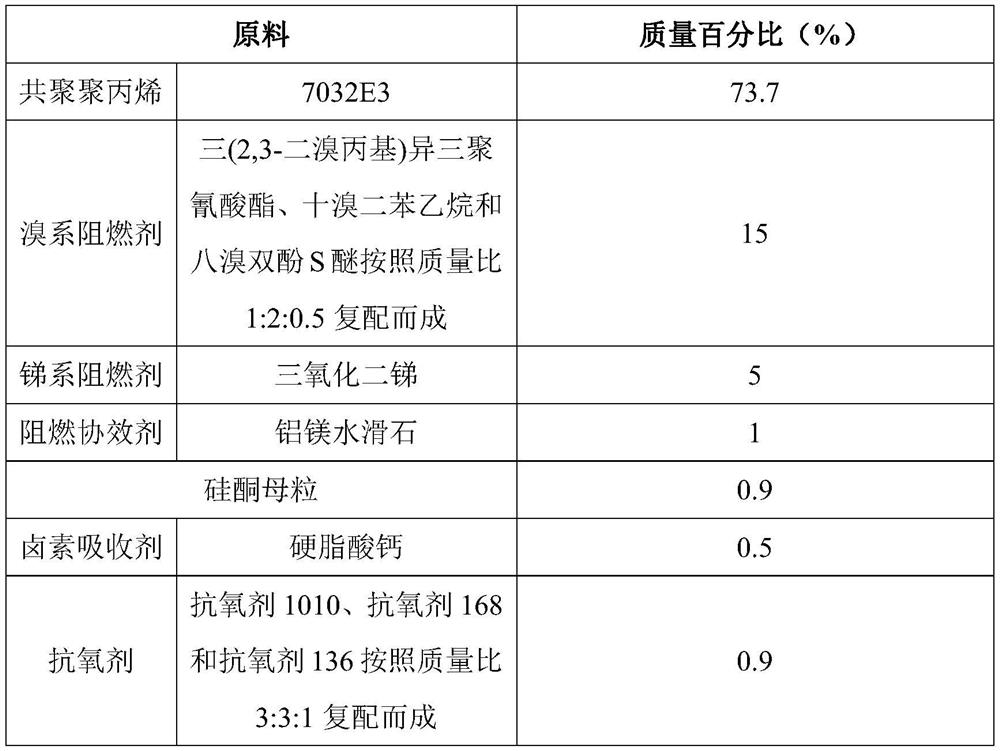

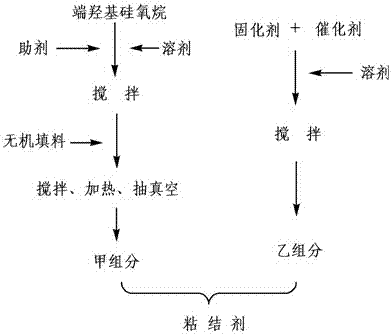

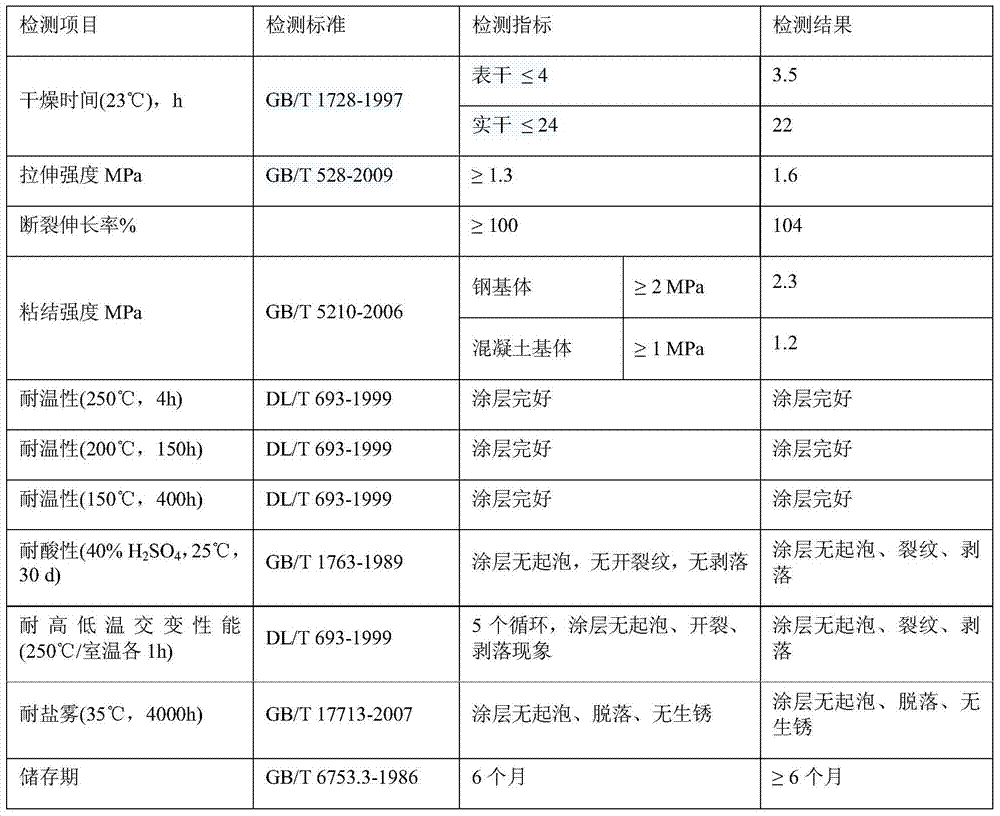

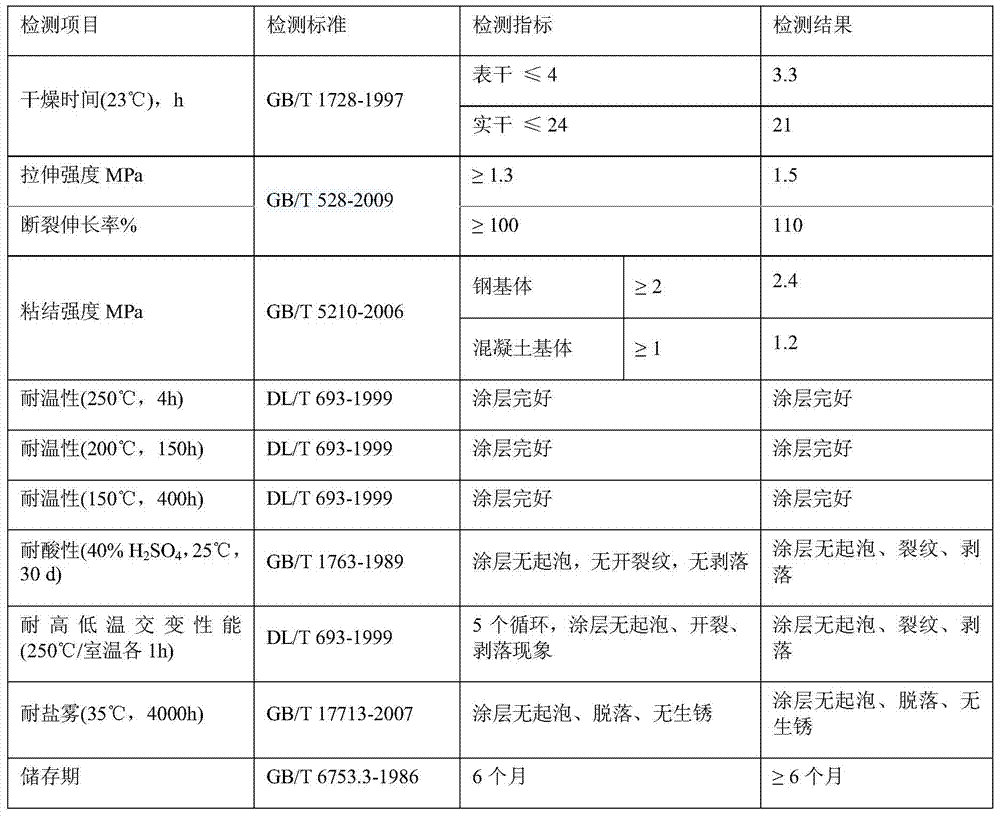

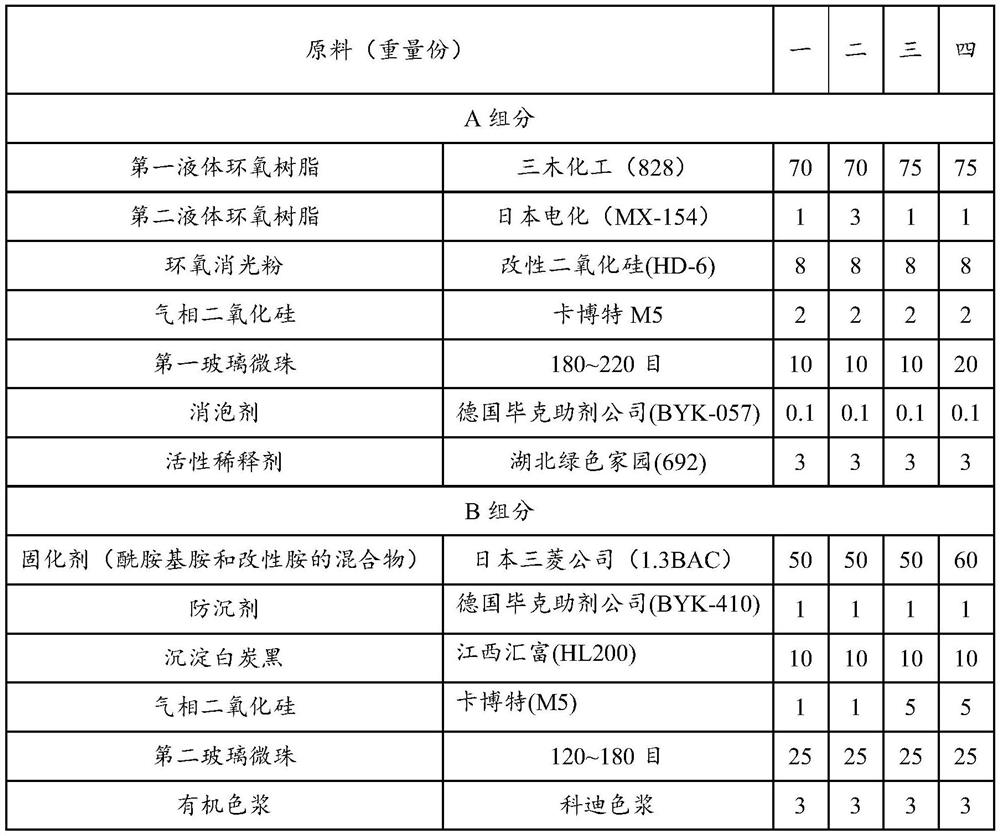

Anti-corrosion two-component adhesive for thermal power plant desulfurization chimney lining and preparation method thereof

ActiveCN104312526BGood resistance to strong acid corrosionGood high temperature aging resistanceNon-macromolecular adhesive additivesMass ratioAdhesive

Owner:CHENGDU LONGZHIQUAN SCI & TECH

A preparation method of an anti-corrosion organic silicon binder for the inner lining of desulfurization chimneys in thermal power plants

InactiveCN105400478BImprove adhesionExcellent resistance to strong acid and alkali corrosionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyethylene glycolStrong acids

The invention relates to a preparing method for a corrosion prevention organic silicon binding agent for a desulfurization chimney liner of a thermal power plant. The preparing method comprises the following steps that firstly, a first component is prepared, wherein hydroxyl-terminated polydimethylsiloxane, polyethylene glycol PEG 600, a defoaming agent, a coupling agent and a solvent a are added into a reaction kettle according to a certain proportion and stirred evenly, then inorganic filler is added multiple times with a small amount, vacuum stirring is carried out for 60 minutes under the condition of the vacuum degree of 0.08 MPa, and the first component of the binding agent is obtained; secondly, a second component is prepared, wherein the curing agent polyisocyanate, a catalyst and a solvent b are added into a reaction kettle according to a certain proportion and stirred evenly, and the second component of the binding agent is obtained; thirdly, the first component and the second component are blended at the mass ration of 20:1 at the room temperature and stirred evenly, and the organic silicon binding agent is obtained. The organic silicon binding agent prepared through the method is high in binding performance, excellent in strong acid and strong base corrosion resistance, and good in high-temperature aging resistance and high-low temperature alternating resistance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

A two-component beautifying agent and its preparation method

ActiveCN111978902BImprove environmental adaptabilityEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesBrickProcess engineering

Owner:中山市卡施力顿建材有限公司

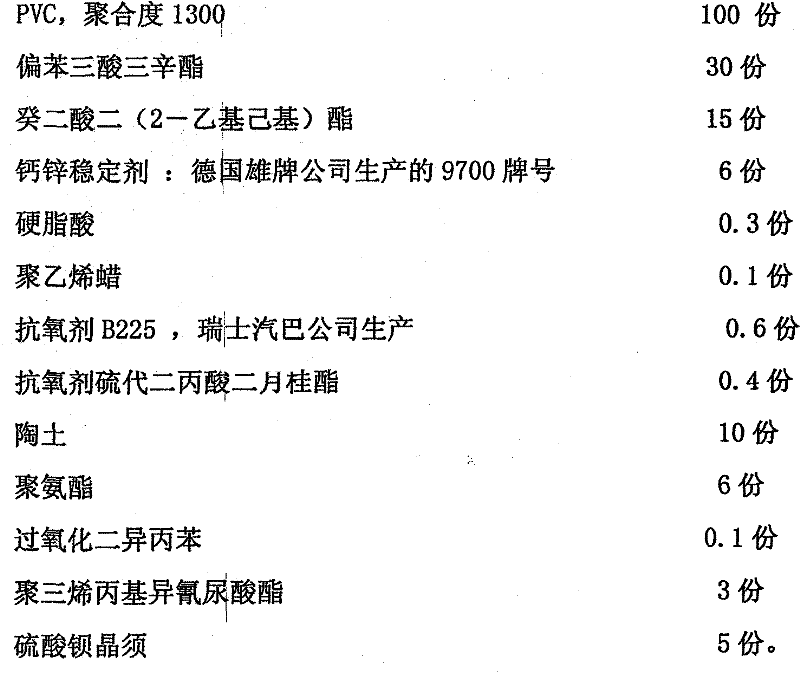

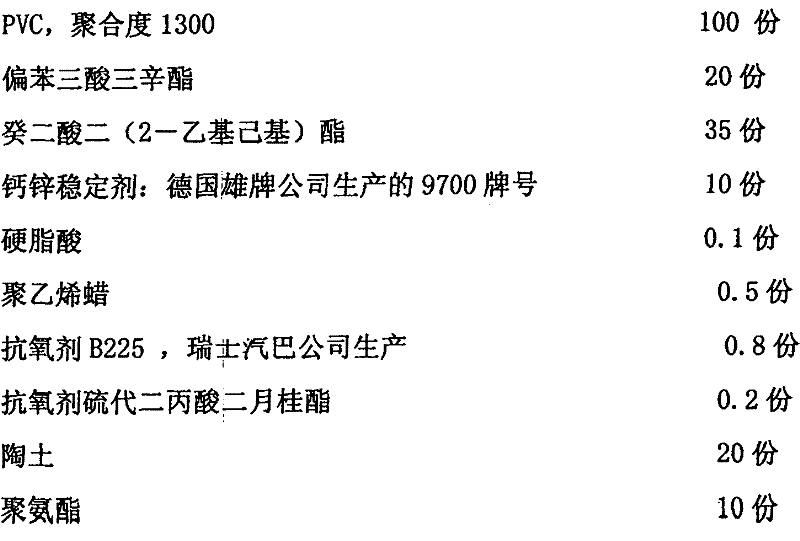

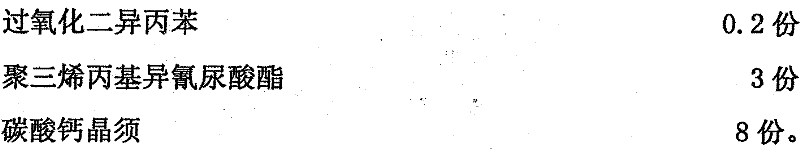

Electric wire and cable soft polychloroethylene plastics for vehicle and preparation method thereof

ActiveCN101386697BHigh tensile strengthImprove wear resistancePlastic/resin/waxes insulatorsPolymer sciencePlastic materials

The invention relates to a cord-cable polyvinyl chloride (PVC) plastic for an automobile, which is formed by chemical crosslinking and mainly comprises PVC, a plasticizing agent, a heat stabilizer, a lubricating agent, an antioxidant, stuffing, a crosslinking agent, an evocating agent, a crosslinking assistant agent and an abrasion resistance modifier. The polymer crosslinking plastic material has the advantages of good abrasion resistance, excellent mechanical property, good high temperature resistance (the heat resistant grade can reach 120 DEG C and the low temperature can reach 40 DEG C below zero), over 70 percent of tensile strength and elongation at break under the ageing condition at 150 DEG C for 168 hours, little weight loss and simple processing technique.

Owner:CHINA PETROLEUM & CHEM CORP

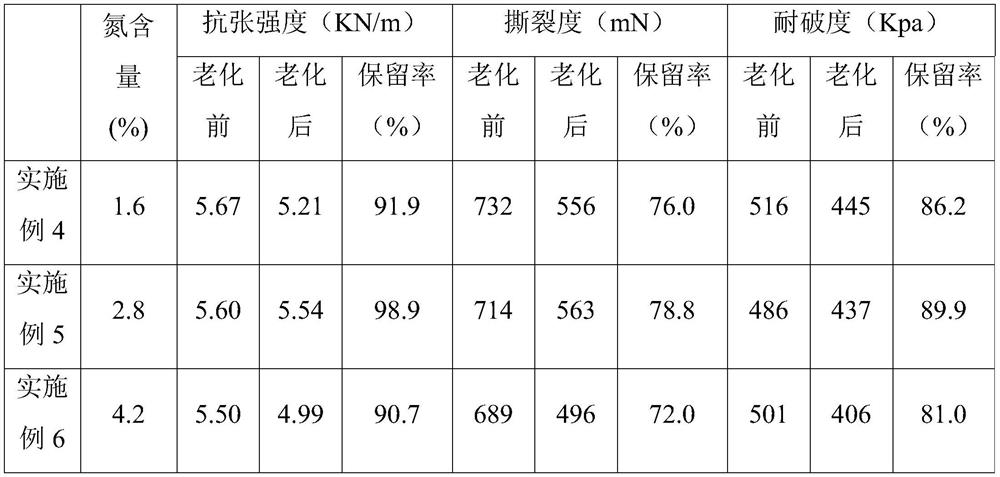

Polyimide compound type high-temperature-aging-resistant auxiliary agent, preparation method thereof, insulating paper and preparation method of insulating paper

ActiveCN113322714AFlexibleThermally stableAgeing prevention agents additionNon-macromolecular organic additionPolyamine CompoundImide

The invention provides a polyimide compound type high-temperature-aging-resistant auxiliary agent, a preparation method thereof, and application of the polyimide compound type high-temperature-aging-resistant auxiliary agent in transformer insulating paper. According to the invention, a polyamine compound and a small molecule amine compound are compounded to obtain the high-temperature-aging-resistant auxiliary agent, the high-temperature-aging-resistant auxiliary agent is added to insulating paper in an adding, spraying, dipping or brushing manner, and finally drying is carried out. The insulating paper obtained by the preparation method provided by the invention has very good insulation performance and very good high-temperature aging resistance, and does not pollute transformer oil.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Nanometer ceria-zirconium solid solution and preparation method thereof

ActiveCN102580719BLarge apertureLarge hole volumeDispersed particle separationIncinerator apparatusRare earthPore diameter

The invention aims to disclose a nanometer ceria-zirconium solid solution and a preparation method thereof. The nanometer ceria-zirconia solid solution comprises the following components according to weight percent: 15 to 65% of cerium oxide, 12 to 70% of zirconia and 10 to 30% of compound oxide composed of other tombarthite oxide except for ceria and zirconium. Compared with the conventional products, the nanometer ceria-zirconium solid solution obtains larger pore diameter and pore volume through modification of a structural directing agent and a dispersing agent, has a favorable capability of resisting high temperature and ageing, and has the advantages of high oxygen storage capability and high speed in oxygen storage and discharge, so that the purposes of the invention are achieved.

Owner:方复(上海)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com