LED (light-emitting diode) organosilicon pouring sealant and application thereof

A silicone potting glue, organic technology, applied in adhesives, electrical components, circuits, etc., can solve the problems of poor selectivity of tackifier, low amount of tackifier, transparency, etc., and achieve light aging resistance, dielectric properties, excellent Effects of dielectric properties and excellent decompression capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

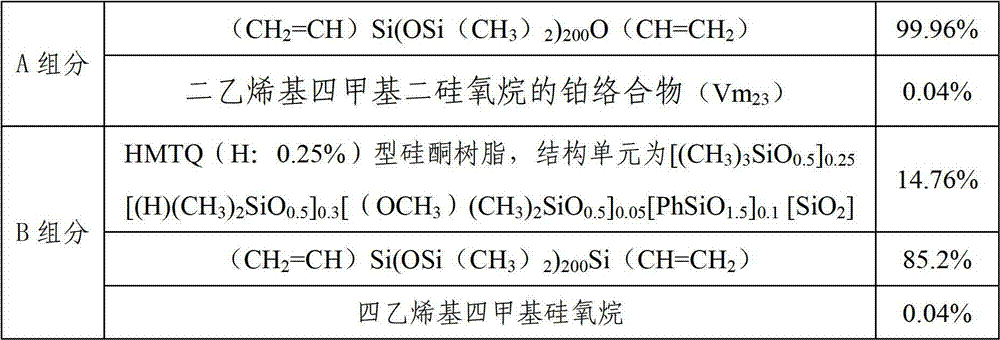

[0029] Table 1: Ingredients and Proportions

[0030]

[0031] The appearance of component A is clear and transparent, and its viscosity is 500mm 2 / s, the appearance of component B is clear and transparent.

[0032] Method for preparing LED components:

[0033] 1. Bake and dry the LED lamp holder and PC lens (Guangdong Hongleida) soldered with chips (Puri 45mil chips) and gold wires.

[0034] 2. Cover the PC lens with the LED lamp holder and press it tightly.

[0035] 3. Mix components A and B evenly to obtain a glue solution of LED silicone potting glue.

[0036] 4. Vacuum the glue solution for defoaming.

[0037] 5. Pour the defoamed glue into the syringe and defoam again.

[0038] 6. Inject the glue into the LED lamp beads.

[0039] 7. Place the LED lamp beads injected with glue at a room temperature of 10-30°C to cure naturally for 24 hours or place them at 50-60°C for 4 hours. In this embodiment, curing is carried out at 25° C. for 24 hours. An LED lamp is prod...

Embodiment 2

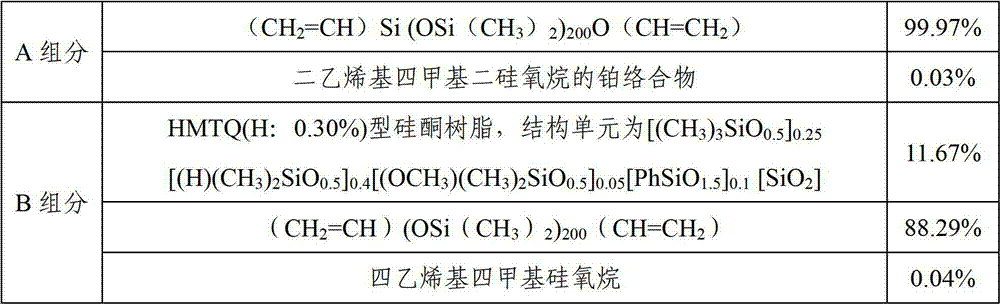

[0043] Table 2: Ingredients and Proportions

[0044]

[0045] A: The appearance of the component is clear and transparent, and its viscosity is 600mm 2 / s B: The appearance of the component is clear and transparent.

[0046] The LED lamp beads injected with the glue solution were placed at room temperature at 30° C. to cure naturally for 24 hours, and other steps were the same as in Example 1 to prepare LED components. The prepared LED lamp was baked at 120°C for 30 minutes and then frozen at -30°C for 30 minutes for a cycle test, and compared after 20 cycles. There is no interlayer between the packaging material and the LED lamp bead bracket, and no interlayer between the PC lens. At a wavelength of 450nm, the light transmittance is 99%, and the dielectric strength is 20kv / mm.

Embodiment 3

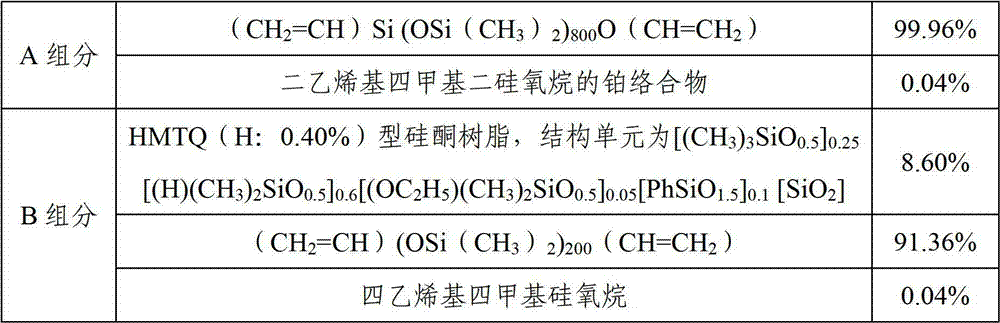

[0048] Table 3: Ingredients and Proportions

[0049]

[0050] The appearance of component A is clear and transparent, and its viscosity is 1000mm 2 / s, the appearance of component B is clear and transparent. Put the glue-injected LED beads at 50-60°C and bake for 4 hours, and other steps are the same as in Example 1 to prepare LED components. In this embodiment, bake at 55° C. for 4 hours. The prepared LED lamp was baked at 120°C for 30 minutes and then frozen at -30°C for 30 minutes for a cycle test, and compared after 20 cycles. There is no interlayer between the packaging material and the LED lamp bead bracket, and no interlayer between the PC lens. At a wavelength of 450nm, the light transmittance is 99%, and the dielectric strength is 20kv / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com