Polyimide compound type high-temperature-aging-resistant auxiliary agent, preparation method thereof, insulating paper and preparation method of insulating paper

A technology of polyimide and high temperature resistance, which is applied in the direction of anti-paper aging agent addition, non-polymer organic compound addition, paper, etc., which can solve the problem of unstable raw material source and quality, influence of additives on insulation performance, and ineffectiveness of nitrogen content And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

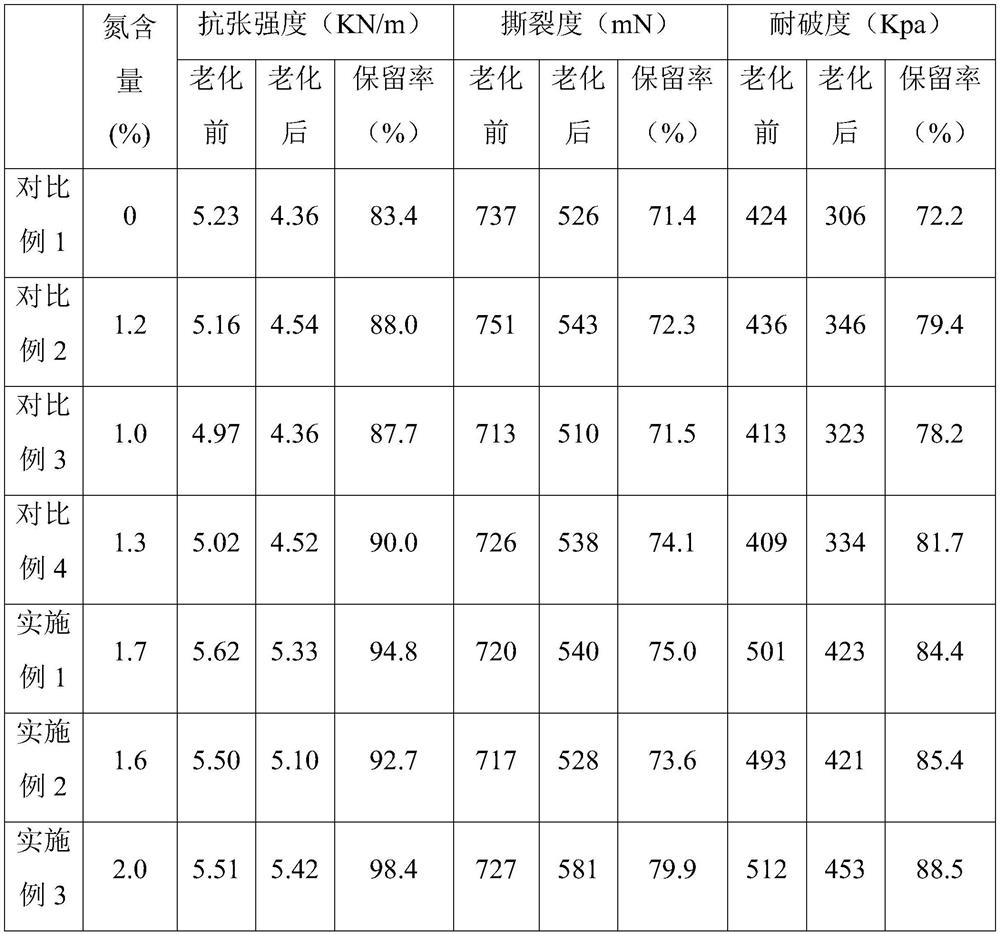

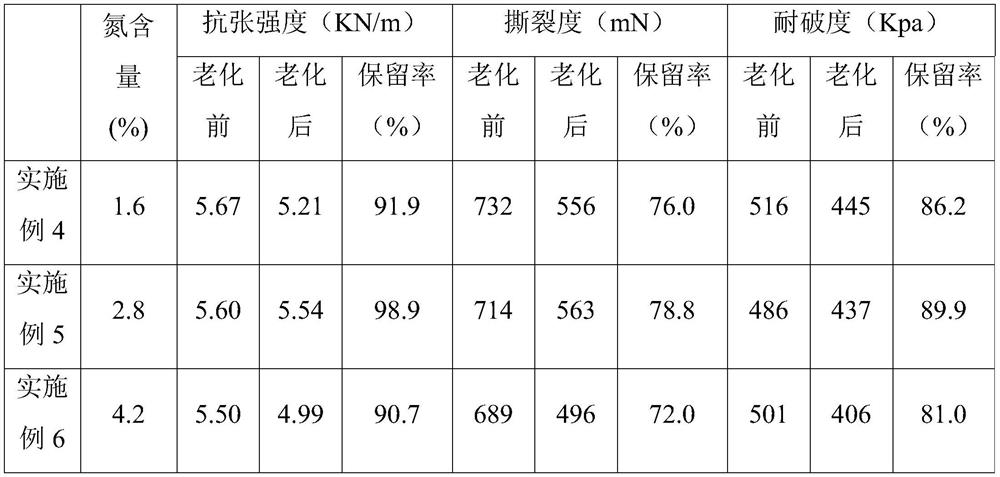

[0037] Mix polyimide, melamine and polyacrylamide in a weight ratio of 1:2:0.1, stir with water at 90°C for 2 hours to dissolve and disperse, add 20% of the absolute dry pulp into the beaten pure wood pulp and mix evenly, and copy it with a paper sample The extractor is copied to 60g / m 2 Quantitative paper is dried at 105°C for 10 minutes to obtain high-temperature aging-resistant insulating paper. The nitrogen content was tested by elemental analysis, and the mechanical properties tested by aging test are shown in Table 1.

Embodiment 2

[0039] Copy the pure wood pulp to 60g / m with a paper sampler 2 Weighted paper, pre-dried to 80% moisture. Dissolve and disperse polyimide, urea, and melamine in DMSO at 90°C for 2 hours in a weight ratio of 1:2:2, and add this additive to the pre-dried insulating paper by impregnating 10% of the dry pulp Dry at 105°C for 10 minutes to obtain high-temperature aging-resistant insulating paper. The nitrogen content was tested by elemental analysis, and the mechanical properties tested by aging test are shown in Table 1.

Embodiment 3

[0041] According to Example 2, polyimide, dicyandiamide, and melamine are dissolved and dispersed with chloroform at 90°C for 2 hours in a weight ratio of 1:2:2, and the additive is added by immersion at 10% of the dry pulp Put it on the pre-dried insulating paper, and dry it at 105°C for 10 minutes to obtain high-temperature aging-resistant insulating paper. The nitrogen content was tested by elemental analysis, and the mechanical properties tested by aging test are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com