Anti-corrosion two-component adhesive for thermal power plant desulfurization chimney lining and preparation method thereof

A chimney lining, two-component technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor bonding performance, long curing time, and limited promotion, and achieve improved Effect of application value, short curing time, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

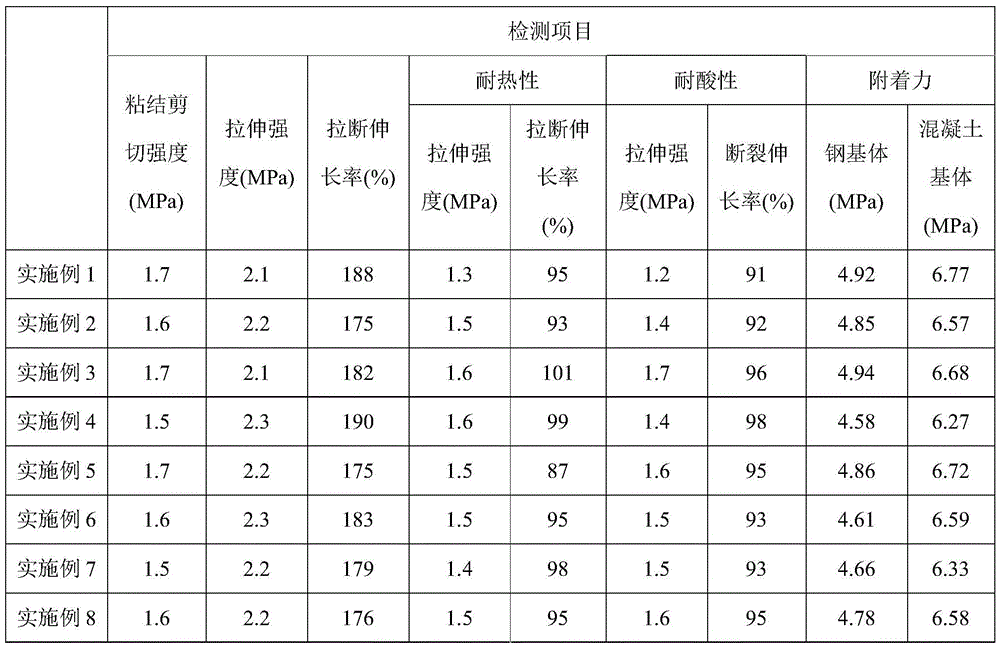

Examples

Embodiment l

[0029] 1) Preparation of component A: Add 100 parts by mass of 107 gum and 30 parts by mass of simethicone to the reaction kettle, vacuumize at 95°C for 5 minutes, continue stirring for 1 hour, then add 8 parts by mass of A mixture of fumed silica (200 mesh) and 1 mass part of coupling-treated glass flakes (200 mesh), after stirring evenly, add 60 mass parts of xylene and petroleum ether mixed solvent (volume ratio is 5:1) and 0.5 parts by mass of KH-550, stirred evenly and cooled to room temperature, then poured out to obtain component A.

[0030] 2) Preparation of component B: at room temperature, mix 1 mass part of methyltrimethoxysilane, 0.4 mass part of dibutyltin dilaurate, 2.5 mass parts of n-butyl titanate, 2.5 mass parts of n-butyl borate Add 10 parts by mass of xylene and petroleum ether mixture (volume ratio 5:1) into the mixer, and stir evenly to obtain component B.

[0031] 3) Prepare component A and component B according to the mass ratio of 12:1, and stir evenl...

Embodiment 2

[0033] 1) Preparation of component A: Add 100 parts by mass of 107 gum and 35 parts by mass of simethicone to the reaction kettle, vacuumize at 95°C for 5 minutes, continue stirring for 1 hour, then add 8 parts by mass of The mixture of fumed white carbon black (200 mesh) and the glass flakes (200 mesh) of coupling treatment of 1 mass part, after stirring evenly, add 55 mass parts of xylene and sherwood oil mixed solvent (volume ratio is 5:1) and 0.5 parts by mass of KH-550, stirred evenly and cooled to room temperature, then poured out to obtain component A.

[0034]2) Preparation of component B: 1.5 parts by mass of methyltrimethoxysilane, 0.5 parts by mass of dibutyltin dilaurate, 2.5 parts by mass of n-butyl titanate, 2.0 parts by mass of n-butyl borate Add 10 parts by mass of xylene and petroleum ether mixture (volume ratio 5:1) into the mixer, and stir evenly to obtain component B.

[0035] 3) Prepare component A and component B according to the mass ratio of 12:1, and ...

Embodiment 3

[0037] 1) Preparation of component A: Add 100 parts by mass of 107 gum and 40 parts by mass of simethicone to the reaction kettle, vacuumize at 95°C for 5 minutes, continue stirring for 1 hour, then add 10 parts by mass of The mixture of fumed white carbon black (200 mesh) and the glass flakes (200 mesh) of coupling treatment of 3 mass parts, after stirring evenly, add 50 mass parts of xylene and sherwood oil mixed solvent (volume ratio is 5:1) and 0.5 parts by mass of KH-550, stirred evenly and cooled to room temperature, then poured out to obtain component A.

[0038] 2) Preparation of component B: 2.0 parts by mass of methyltrimethoxysilane, 0.6 parts by mass of dibutyltin dilaurate, 2.0 parts by mass of n-butyl titanate, 2.0 parts by mass of n-butyl borate Add 10 parts by mass of xylene and petroleum ether mixture (volume ratio 5:1) into the mixer, and stir evenly to obtain component B.

[0039] 3) Prepare component A and component B at a mass ratio of 12:1, stir evenly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com