High-temperature ageing resistant and flame-resistant polypropylene material used for corrugated pipes and preparation method of polypropylene material

A flame-retardant polypropylene and high-temperature-resistant technology, which is applied in the field of high-temperature aging-resistant flame-retardant polypropylene materials and their preparation, can solve problems such as affecting production efficiency and product quality, easy rupture of corrugated pipes, and uneven surface of corrugated pipes, etc. It is not easy to squeeze and burst, the preparation method is simple and efficient, and the flame retardant effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

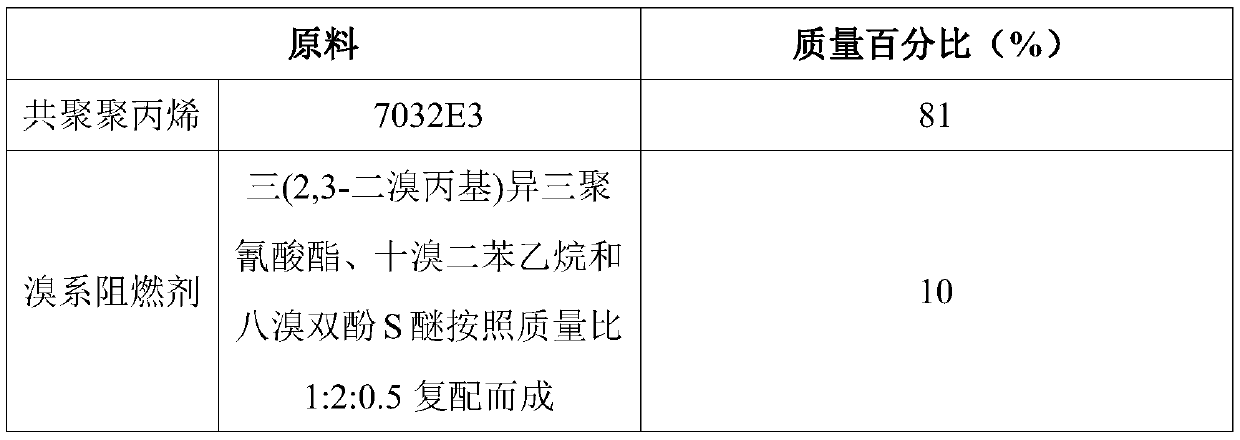

[0053] A high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes, its raw material composition is shown in the following table:

[0054] Table 1 A raw material composition table of a high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes

[0055]

[0056]

[0057] The preparation method of the above-mentioned high-temperature aging-resistant flame-retardant polypropylene material for bellows comprises the following steps:

[0058] 1) Add brominated flame retardants, antimony-based flame retardants, flame retardant synergists, silicone masterbatches, halogen absorbers and antioxidants into a high-speed mixer, mix evenly at 50°C, and then add copolymerized polypropylene and Toughness modifier, mixed uniformly at 50°C;

[0059] 2) Transfer the material in the high-speed mixer to the extruder for extrusion (extrusion temperature is 170-190°C), cooling, stranding, and pelletizing to obtain h...

Embodiment 2

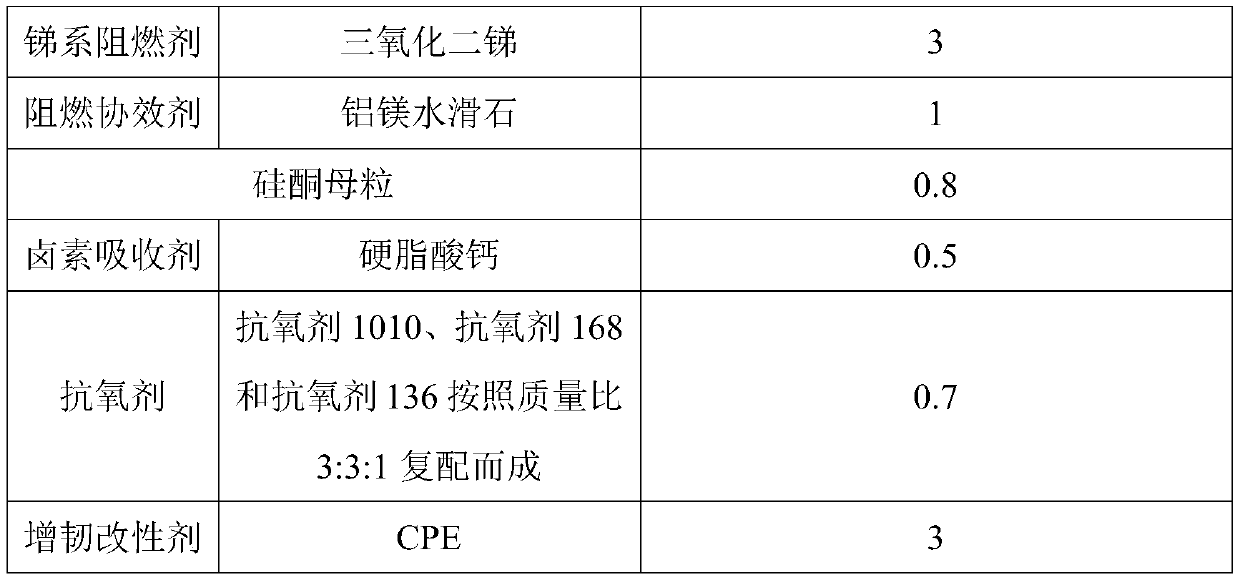

[0061] A high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes, its raw material composition is shown in the following table:

[0062] Table 2 A raw material composition table of a high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes

[0063]

[0064]

[0065] The preparation method of the above-mentioned high-temperature aging-resistant flame-retardant polypropylene material for bellows comprises the following steps:

[0066] 1) Add brominated flame retardants, antimony-based flame retardants, flame retardant synergists, silicone masterbatches, halogen absorbers and antioxidants into a high-speed mixer, mix evenly at 50°C, and then add copolymerized polypropylene and Toughness modifier, mixed uniformly at 50°C;

[0067] 2) Transfer the material in the high-speed mixer to the extruder for extrusion (extrusion temperature is 170-190°C), cooling, stranding, and pelletizing to obtain h...

Embodiment 3

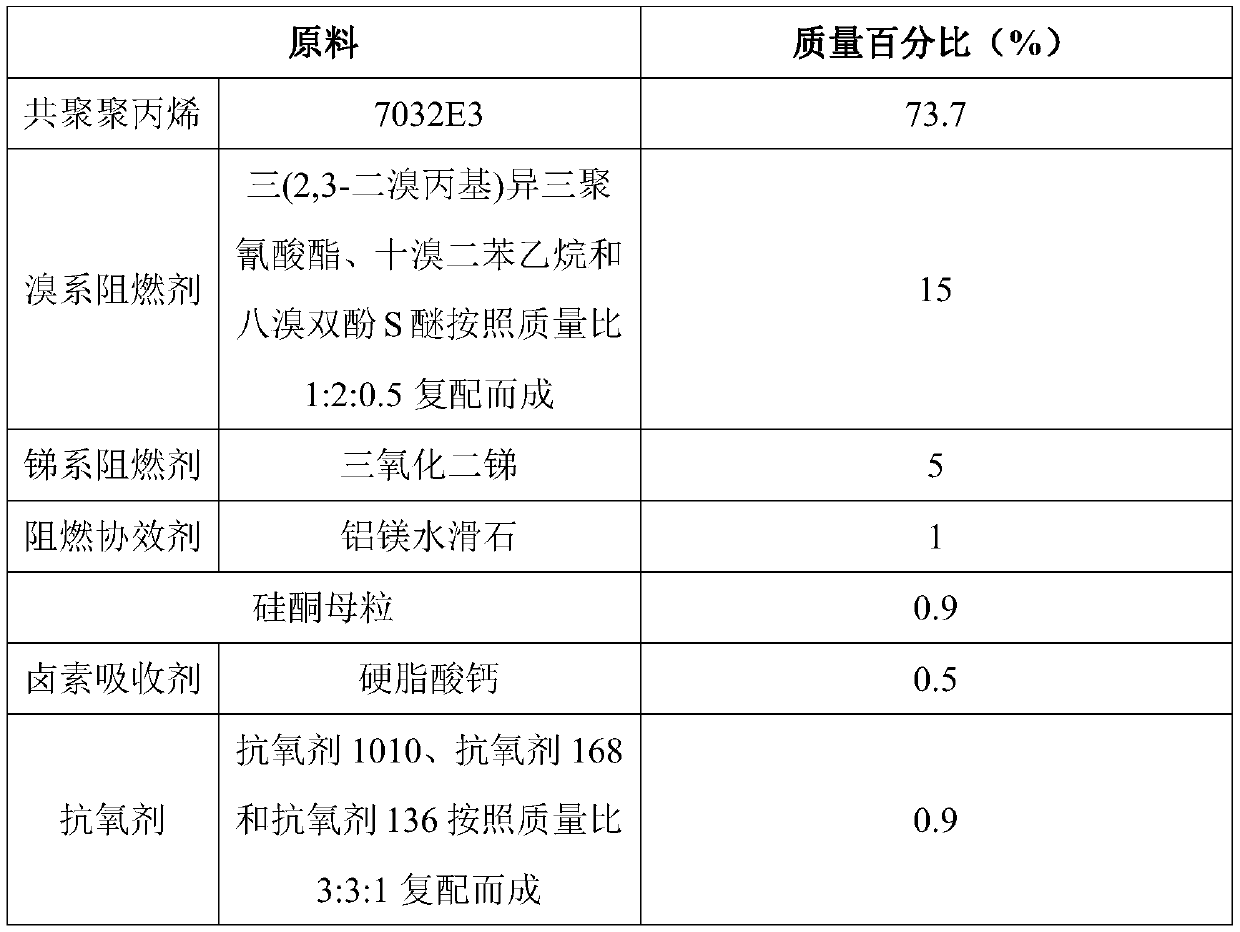

[0069] A high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes, its raw material composition is shown in the following table:

[0070] Table 3 A raw material composition table of a high-temperature aging-resistant flame-retardant polypropylene material used for corrugated pipes

[0071]

[0072] The preparation method of the above-mentioned high-temperature aging-resistant flame-retardant polypropylene material for bellows comprises the following steps:

[0073] 1) Add brominated flame retardants, antimony-based flame retardants, flame retardant synergists, silicone masterbatches, halogen absorbers and antioxidants into a high-speed mixer, mix evenly at 50°C, and then add copolymerized polypropylene and Toughness modifier, mixed uniformly at 50°C;

[0074] 2) Transfer the material in the high-speed mixer to the extruder for extrusion (extrusion temperature is 170-190°C), cooling, stranding, and pelletizing to obtain high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com