Cerium-zirconium-barium-copper oxide catalyst for purifying tail gas of lean-burn engine and preparation method thereof

A lean-burn engine, copper oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low copper content, unsatisfactory treatment effect, Reduce NO conversion temperature and other issues to achieve good high temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

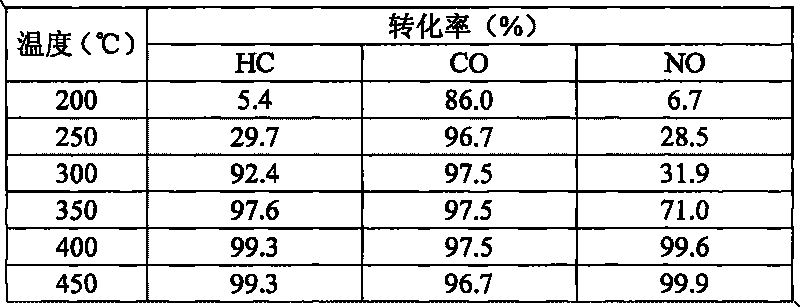

[0020] Example 1: Ce 7 Zr 28 Ba 1 Cu 1.25 The catalytic effect of the catalyst

[0021] 0.00583mol of Ce(NO 3 ) 3 ·6H 2 O, 0.0233mol of Zr(NO 3 ) 4 ·5H 2 O and 0.000833mol of Ba(NO 3 ) 2 Soluble in water to form Ce 3+ 、Zr 4+ and Ba 2+ A cation solution with a molar ratio of 7:28:1 and a total cation concentration of 0.2mol / L.

[0022] Weigh 0.05mol of NH 4 HCO 3 Solid, dissolved in water to form a 0.2mol / L aqueous solution, and heated in a constant temperature water bath at 35°C, and the cationic solution was added dropwise with stirring at a rate of 10ml / min. After the dropwise addition was completed, the reaction was continued for two hours to complete the reaction. Then it was aged at room temperature for 18 hours, and the solid obtained by filtering was dried at 110°C for 11 hours, ground, and calcined at 700°C for 2 hours to obtain the Ce-Zr-Ba composite oxide. According to X-ray diffraction analysis, the Ce-Zr-Ba composite oxide forms a solid solution s...

Embodiment 2

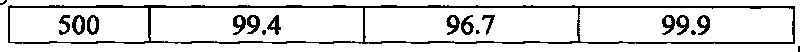

[0028] Example 2: Ce 5.5 Zr 22 Ba 1 Cu 1 The catalytic effect of the catalyst

[0029] Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Ba(NO 3 ) 2 and Cu(NO 3 ) 2 ·3H 2 O, NH 4 HCO 3 The number of moles is Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O and Ba(NO 3 ) 2 2 times of the sum of the number of moles, the Ce, Zr, Ba and Cu oxide mol ratios are 5.5: 22: 1: 1 obtained by the operation steps of Example 1 5.5 Zr 22 Ba 1 Cu 1 Catalyst, test activity under the activity evaluation condition of embodiment 1. The conversion rates of HC, CO and NO on the catalyst are as follows:

[0030]

[0031] Visible, by the above Ce 5.5 Zr 22 Ba 1 Cu 1 Catalyst purification treatment simulates lean-burn motor vehicle exhaust, and can basically remove HC (conversion rate above 80%) above 350°C, and can completely remove CO at the same time, and can also completely remove NO when it reaches 400-450°C.

Embodiment 3

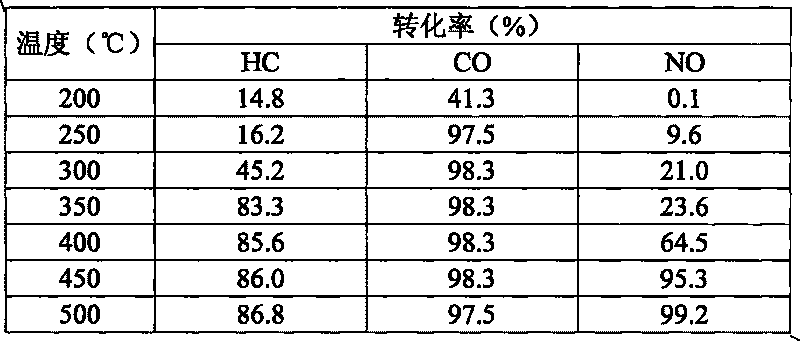

[0032] Example 3: Ce 4.5 Zr 18 Ba 1 Cu 0.83 The catalytic effect of the catalyst

[0033] Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Ba(NO 3 ) 2 and Cu(NO 3 ) 2 ·3H 2 O, NH 4 HCO 3 The number of moles is Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O and Ba(NO 3 ) 2 2 times of the sum of the number of moles, the Ce, Zr, Ba and Cu oxide mol ratios are 4.5: 18: 1: 0.83 obtained by the operation steps of Example 1 4.5 Zr 18 Ba 1 Cu 0.83 Catalyst, and test activity under the activity evaluation condition of embodiment 1. The conversion rates of HC, CO and NO on the catalyst are as follows:

[0034]

[0035] Visible, by the above Ce 4.5 Zr 18 Ba 1 Cu 0.83 Catalyst purification treatment simulates lean-burn motor vehicle exhaust, HC and CO can be completely removed at 300-350°C, and NO can also be completely removed at 400-450°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com