A process for microwave synergistic catalytic oxidation of vocs

A technology of synergistic catalysis and catalytic oxidation, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of small specific surface area and limit the use of catalyst carriers, achieve rapid temperature rise, facilitate engineering applications, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

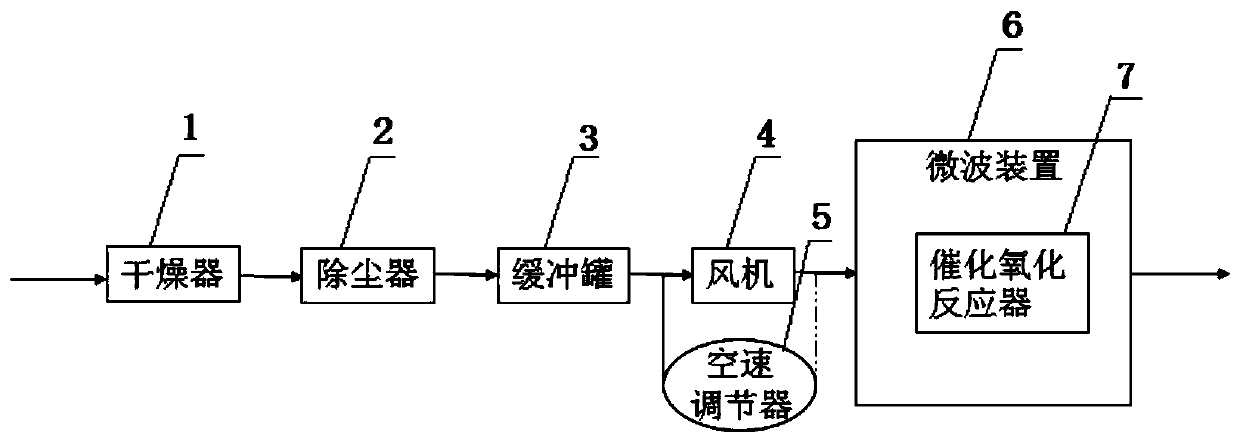

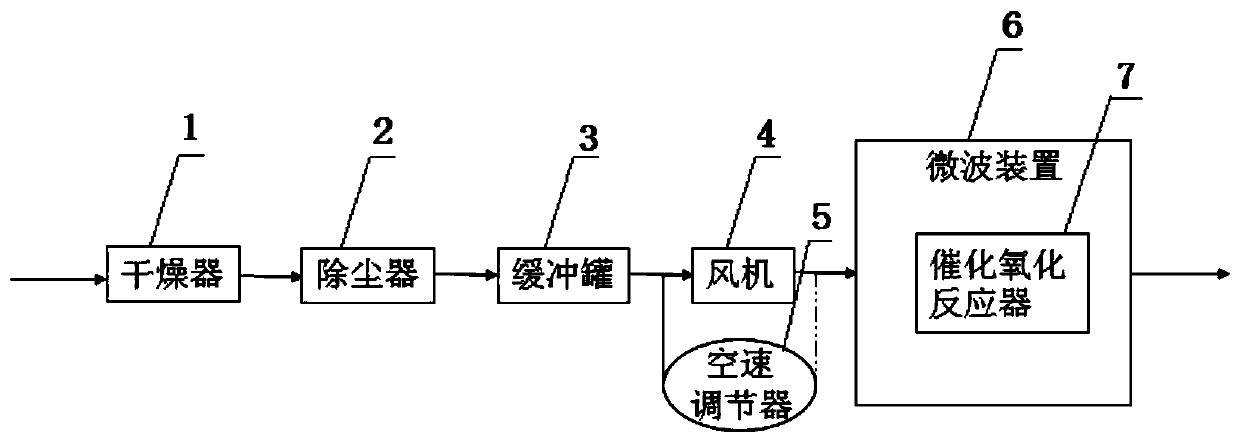

[0035] The waste gas containing toluene was degraded by microwave synergistic catalytic oxidation technology on the gas dynamic simulation experiment system. The catalyst mixed and diluted with quartz sand is filled in the catalytic reactor, the inlet and outlet gases are analyzed by gas chromatography (GCT890), and the chromatographic column filler is 5A molecular sieve. The catalyst is silicon carbide modified alumina supported Co 3 o 4 and CeO 2 , where SiC doping mass fraction is 5%, Co 3 o 4 The loading amount is 5%, CeO 2 The loading is 2.5% and the rest is alumina. The composition of the reaction gas is: toluene injection concentration: 600ppm; air flow rate 0.08m 3 / h, microwave power 100w. The reaction gas is pumped into the catalytic oxidation reactor in the microwave device through the fan, relying on microwave heating and inducing catalytic oxidation, cooperating with the adsorption and catalytic oxidation of the catalyst, the degradation efficiency of tolue...

Embodiment 2

[0037] The waste gas containing toluene was degraded by microwave synergistic catalytic oxidation technology on the gas dynamic simulation experiment system. The catalyst mixed and diluted with quartz sand is filled in the catalytic reactor, and the inlet and outlet gases are analyzed by gas chromatography (GCT890), and the chromatographic column filler is 5A molecular sieve. The catalyst is silicon carbide modified alumina supported Co 3 o 4 and CeO 2 , where SiC doping mass fraction is 5%, Co 3 o 4 The loading amount is 5%, CeO 2 The loading is 2.5% and the rest is alumina. The composition of the reaction gas is: toluene injection concentration: 600ppm; air flow rate 0.08m 3 / h, microwave power 300w. At 240°C, the degradation efficiency of toluene can reach 94.5%.

Embodiment 3

[0039] The waste gas containing toluene was degraded by microwave synergistic catalytic oxidation technology on the gas dynamic simulation experiment system. The catalyst mixed and diluted with quartz sand is filled in the catalytic reactor, and the inlet and outlet gases are analyzed by gas chromatography (GCT890), and the chromatographic column filler is 5A molecular sieve. The catalyst is silicon carbide modified alumina supported Co 3 o 4 and CeO 2, where SiC doping mass fraction is 5%, Co 3 o 4 The loading amount is 10%, CeO 2 The loading is 5% and the rest is alumina. The composition of the reaction gas is: toluene injection concentration: 600ppm; air flow rate 0.08m 3 / h, microwave power 300w. At 240°C, the degradation efficiency of toluene can reach 95.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com