A method for improving catalytic oxidation activity of vocs catalyst

A catalytic oxidation and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of limited resources, limited large-scale sustainable application, high use cost, and achieve lower catalytic oxidation temperature, Good low temperature catalytic oxidation activity and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

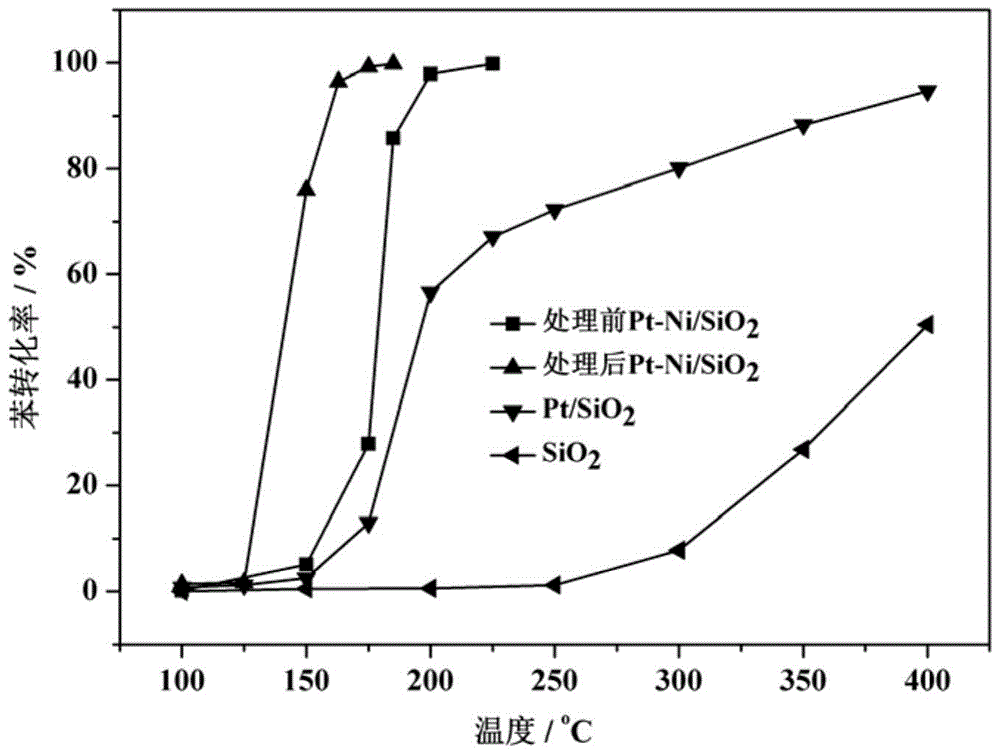

Embodiment 1

[0046] Pt-Ni / SiO prepared by flame spray pyrolysis 2 Catalyst powder (Pt, Ni molar ratio is 1:1), at 300°C, in H 2 After the atmosphere was reduced for 1 hour, it was naturally cooled to room temperature, and the reduced powder was immersed in 0.1 mol / L nitric acid, and etched for 12 hours. The acid liquid and the powder are separated by centrifugation, washed with distilled water, centrifuged, and vacuum-dried in a vacuum oven to obtain a catalyst powder product with an active component content of 1%.

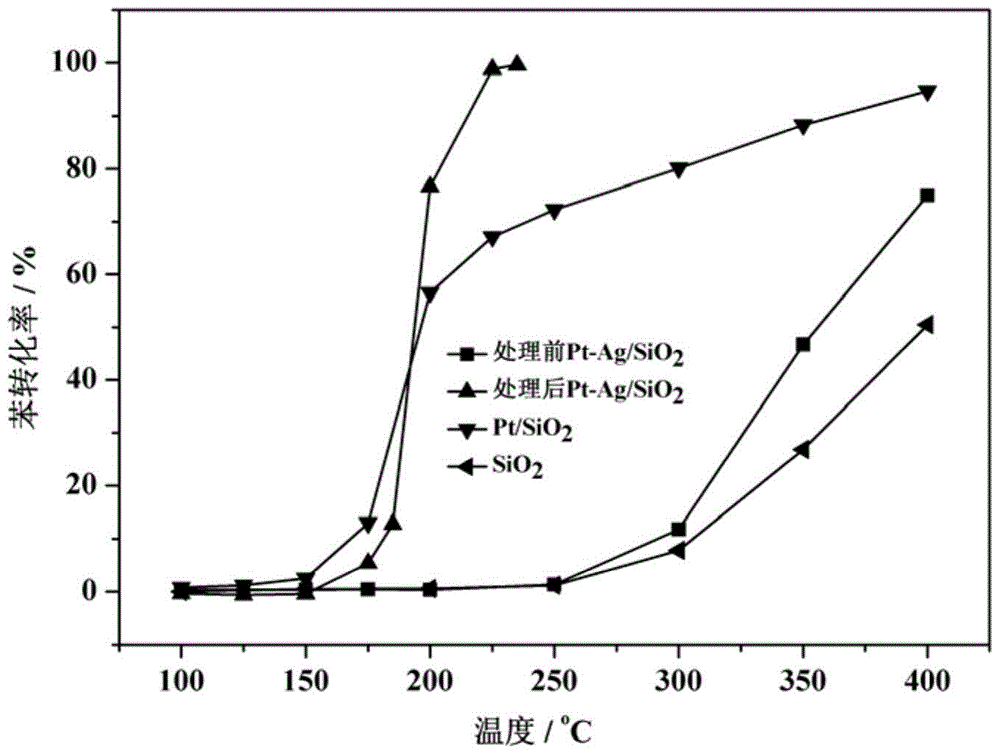

Embodiment 2

[0048] Pt-Ag / SiO prepared by flame spray pyrolysis 2 Catalyst powder (Pt, Ag molar ratio is 1:1), at 1100°C, in H 2 After the atmosphere was reduced for 1 hour, it was naturally cooled to room temperature, and the reduced powder was immersed in 2mol / L nitric acid, and etched for 6 hours. The acid liquid and the powder are separated by centrifugation, washed with distilled water, centrifuged, and vacuum-dried in a vacuum oven at 50°C to obtain a catalyst powder product with an active component content of 1%.

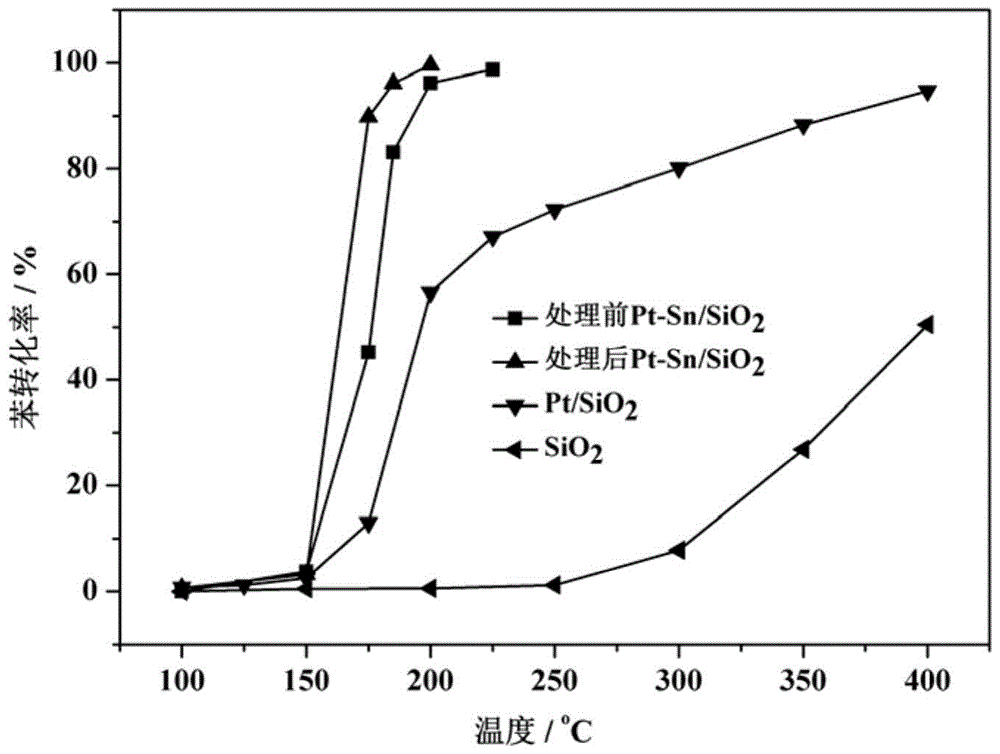

Embodiment 3

[0050] Pt-Ni / TiO prepared by flame spray pyrolysis 2 Catalyst powder (Pt, Ni molar ratio is 1:1), at 500°C, in H 2 After the atmosphere was reduced for 2 hours, it was naturally cooled to room temperature, and the reduced powder was immersed in 1 mol / L hydrochloric acid, and etched for 12 hours. The acid liquid and the powder are separated by centrifugation, washed with distilled water, centrifuged, and vacuum-dried in a vacuum oven at 50°C to obtain a catalyst powder product with an active component content of 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com